Controllers - Engr. Ijlal Haider

advertisement

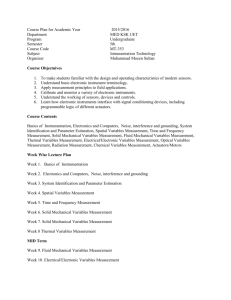

1 In The Name of Allah The Most Beneficent The Most Merciful ECE4545: Control Systems Lecture: Elements of Control Systems Design Engr. Ijlal Haider UoL, Lahore 2 A modern industrial plant: A section of the OMV Oil Refinery in Austria 4 Outline Control Talk Open Loop to Closed Loop Instruments Desirable Attributes of Instruments System Integration Process Facility Consideration Cost Benefit Analysis Various Sensor Types Actuators and Control 5 Control Talk Manual vs. Automatic Control in a Heat Exchanger (an example of process control) 6 Control Talk In a process-control facility the controller is not necessarily limited to one variable, but can measure and control many variables. A good example of the measurement and control of multivariable that we encounter on a daily basis is given by the processor in the automobile engine. List of some functions performed by the engine processor. Most of the controlled variables are six or eight devices depending on the number of cylinders in the engine. The engine processor has to perform all these functions in approximately 5 ms. 7 Control Talk Automobile Engine Control Processor: Multivariable Control Talk Signals & Systems Terminology Control Talk Typical Control Hierarchy 10 Open Loop to Closed Loop Approach Control System Design, Goodwin, Graebe, Salgado 11 Instruments Instrument is the name of any of the various device types for measuring, indicating or computing physical quantities or conditions, performance, position, direction, and the like. Transducers are devices that can change one form of energy to another, e.g. a resistance thermometer or a thermocouple gives output that is proportional to temperature Converters are devices that are used to change the format of a signal without changing the energy form, i.e. a change from a voltage to a current signal. 12 Instruments Sensors are devices that can detect physical variables and have the ability to give a measurable output that varies in relation to the amplitude of the physical variable. The human body has sensors in the fingers that can detect surface roughness, temperature, and force. A thermometer is a good example of a line-of-sight sensor Diaphragm pressure sensor, a strain transducer may be required to convert the deformation of the diaphragm into an electrical or pneumatic signal before it can be measured. 13 Instruments Actuators are devices that are used to control an input variable in response to a signal from a controller. typical actuator will be a flow-control valve that can control the rate of flow of a fluid in proportion to the amplitude of an electrical signal from the controller. magnetic relays that turn electrical power on and off. 14 Instruments Controllers are devices that monitor signals from transducers and take the necessary action to keep the process within specified limits according to a predefined program (algorithm) by activating and controlling the necessary actuators. PLC, Microcontrollers, PC etc. PLC are industrial computers, Graphical programming (Ladder Logic) 15 16 Transmissions Transmitters Current 4-20 mA, 10-50mA Voltage 0-5 V, 0-10 V, 0-12 V Pneumatic 3-15 psi, 6-30 psi Digital Transmission Fast and requires less power Samplers and Reconstructors Conversions Smart Sensors for 17 Transmissions Industrial Networks Foundation Fieldbus (US) and Profibus (EU) Telemetry (Wireless transmission) Desirable Attributes of Instruments Reliability. It should operate within the necessary range. Accuracy. For a variable with a constant value, they should settle to the correct value. Responsiveness. If the variable changes, the measurement should be able to follow the changes. Slow responding measurements can, not only affect the quality of control but can actually make the feedback loop unstable. Loop instability may arise even though the loop has been designed to be stable assuming an exact measurement of the process variable. Desirable Attributes of Instruments Noise immunity. The instruments, including the transmission path, should not be significantly affected by exogenous signals such as measurement noise. Linearity. If the instrument system is not linear, then at least the nonlinearity should be known so that it can be compensated. Non intrusive. The instrument should not significantly affect the behaviour of the plant. System Integration Success in control engineering depends on taking a holistic viewpoint. Some of the issues are: plant, i.e. the process to be controlled objectives sensors actuators communications computing architectures and interfacing algorithms accounting for disturbances and uncertainty homogeneity Plant The physical layout of a plant is an intrinsic part of control problems. Thus a control engineer needs to be familiar with the "physics" of the process under study. This includes a rudimentary knowledge of the basic energy balance, mass balance and material flows in the system. Objectives Before designing sensors, actuators or control architectures, it is important to know the goal, that is, to formulate the control objectives. This includes what does one want reduction, yield increase,...) achieve (energy what variables need to be controlled to achieve these objectives what level of (accuracy, speed,...) to performance is necessary Sensors Sensors are the eyes of control enabling one to see what is going on. Indeed, one statement that is sometimes made about control is: If you can measure it, you can control it. Actuators Once sensors are in place to report on the state of a process, then the next issue is the ability to affect, or actuate, the system in order to move the process from the current state to a desired state A Modern Rolling Mill A typical industrial control problem will usually involve many different actuators - see below: Typical flatness control set-up for rolling mill A Modern Rolling Mill Communications Interconnecting sensors to controllers and actuators, involves the use of communication systems. A typical plant can have many thousands of separate signals to be sent over long distances. Thus the design of communication systems and their associated protocols is an increasingly important aspect of modern control engineering. Computing In modern control systems, the connection between sensors and actuators is invariably made via a computer of some sort. Thus, computer issues are necessarily part of the overall design. Current control systems use a variety of computational devices including DCS's (Distributed Control Systems), PLC's (Programmable Logic Controllers), PC's (Personal Computers), etc. Architectures and Interfacing The issue of what to connect to what is a nontrivial one in control system design. One may feel that the best solution would always be to bring all signals to a central point so that each control action would be based on complete information (leading to so called, centralized control). However, this is rarely (if ever) the best solution in practice. Indeed, there are very good reasons why one may not wish to bring all signals to a common point. Obvious objections to this include complexity, cost, time constraints in computation, maintainability, reliability, etc. Algorithms (Controller) Finally, we come to the real heart of control engineering i.e. the algorithms that connect the sensors to the actuators. It is all to easy to underestimate this final aspect of the problem. As a simple example from our everyday experience, consider the problem of playing tennis at top international level. One can readily accept that one needs good eye sight (sensors) and strong muscles (actuators) to play tennis at this level, but these attributes are not sufficient. Indeed eye-hand coordination (i.e. control) is also crucial to success. In summary: Sensors provide the eyes and actuators the muscle but control science provides the finesse Better Sensors Provide better Vision Better Actuators Better Control Provide more Muscle Provides more finesse by combining sensors and actuators in more intelligent ways Disturbances and Uncertainty One of the things that makes control science interesting is that all real life systems are acted on by noise and external disturbances. These factors can have a significant impact on the performance of the system. As a simple example, aircraft are subject to disturbances in the form of windgusts, and cruise controllers in cars have to cope with different road gradients and different car loadings. Homogeneity A final point is that all interconnected systems, including control systems, are only as good as their weakest element. The implications of this in control system design are that one should aim to have all components (plant, sensors, actuators, communications, computing, interfaces, algorithms, etc) of roughly comparable accuracy and performance. 35 Process Facility Consideration The process facility has a number of basic requirements including Safety Precautions for Human, Machine and Facility Environmental and Social Impact Waste treatment, Disposal, Emissions, Noise Well-regulated, reliable supply of Sensors, Alarms, Switches, Grounding, EMI (isolating transformers) Electricity, Water and Air Installation and Maintenance Cost Benefit Analysis In order to make progress in control engineering (as in any field) it is important to be able to justify the associated expenditure. This usually takes the form of a cost benefit analysis. 37 Various Sensors Temperature and Heat Flow Pressure Level Light and Sound Humidity, Density, Viscosity and pH Motion and Position Force, Torque and Load Smoke, Fire and Chemical 38 Actuators and Control Pressure Control Actuators Flow Control Actuators Globe Valve Other Valves Power Control Actuators Regulators Valves Electronic Control Devices Magnetic Control Devices Motors Servo Stepper 39 Thank You!