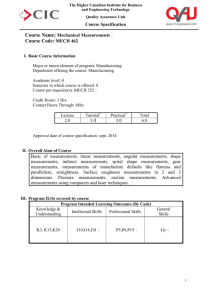

COURSE TITLE (COURSE CODE)

advertisement

The Higher Canadian Institute for Business and Engineering Technology Quality Assurance Unit Course Specification Course Name: Manufacturing Technology II Course Code: MECH 252 I. Basic Course Information Major or minor element of program Manufacturing: Department offering the course: Manufacturing Academic level:2nd Semester in which course is offered: Fall Course pre-requisite(s): MECH 151 Credit Hours: 3 Contact Hours Through: Lecture 2.0 Tutorial* 1.0 Practical* 2.0 Total 5.0 Approval date of course specification: September 2013 II. Overall Aims of Course Automation principles- cutting tool materials- tool and operation of machining, drilling operation and tools, plant planning, milling tool and operations, sharpening tools and operations, tools and work pieces fixtures, cutting time calculation, non traditional cutting process, metal forming: mechanical behaviour of metals- plastic deformation- temperature effect on the plastic behavior, cold and hot work operations, sheet metal forming, forming processes, forging types, planning, extrusion, types of drawing ( bars, wires, tubes and deep drawing. Sheet metal working (stamping, pressing, trimming, bending and coining). heat treatments for alloys, melting and phase change in alloys. Ferrous alloy heat treatment. Nonferrous alloy heat treatment. III. Program ILOs covered by course Program Intended Learning Outcomes (By Code) Knowledge & Intellectual Skills Professional Skills Understanding K3,K8,K13 I8,I18 P1,P2,P4 General Skills Gc 1 The Higher Canadian Institute for Business and Engineering Technology Quality Assurance Unit Course Specification IV. Intended Learning Outcomes of Course (ILOs) a. Knowledge and Understanding On completing the course, students should be able to: K3. Characteristics of engineering materials related to the discipline. K8.Current engineering technologies as related to disciplines. K13. Concepts, principles and theories relevant to Mechanical Engineering and manufacture; b. Intellectual/Cognitive Skills On completing the course, students should be able to: I8. Select and appraise appropriate ICT tools to a variety of engineering problems. I18.Select appropriate manufacturing method considering design requirements c. Practical/Professional Skills On completing the course, students should be able to: P1. Apply knowledge of mathematics, science, information technology, design,business context and engineering practice integrally to solve engineering problems. P2. Professionally merge the engineering knowledge, understanding, and feedback to improve design, products and/or services. P4. Practice the neatness and aesthetics in design and approach. d. General and Transferable Skills On completing the course, students should be able to: Gc. Communicate effectively. V. Course Matrix Contents Main Topics / Chapters 1- Introduction 2- Automation principles 34567891011121314- cutting tool materials, tool and operation of machining drilling operation and tools , plant planning milling tool and operations sharpening tools and operations tools and work pieces fixtures cutting time calculation non traditional cutting process metal forming: mechanical behaviour of metalssheet metal forming, forming processes forging types, planning, extrusion, types of drawing heat treatments for alloys, melting and phase change in alloys Ferrous alloy heat treatment. Nonferrous alloy heat treatment Net Teaching Weeks 1 1 1 Course ILOs Covered by Topic (By ILO Code) K&U I.S. P.S. G.S. K3,K8 I8 P1,P2 Gc K8,K13 I8,I18 P2,P4 Gc Gc K3,K8 I18 P4 1 K3,K13 I8 P2 Gc 1 1 1 1 1 1 K8,K13 K3,K8 K8 K13 K3,K13 I8,I18 I8 I8 I18 I8 P1,P2 P4 P2,P4 P2 P4 K8,K13 I18 P1,P4 Gc Gc Gc Gc Gc Gc 1 K3,K8 I8 P2,P4 Gc 1 K8,K13 I18 P2 Gc K3,K13 I8,I18 P4 K8,K13 I8,I18 P1,P2 Duration (Weeks) 1 1 Gc Gc 14 2 The Higher Canadian Institute for Business and Engineering Technology Quality Assurance Unit Course Specification VI. Course Weekly Detailed Topics / hours / ILOs Week No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Total Hours Sub-Topics Introduction Automation principles cutting tool materials, tool and operation of machining drilling operation and tools , plant planning milling tool and operations sharpening tools and operations 5 2 3 5 5 5 Midterm Exam 5 5 5 2 2 2 3 3 3 2 2 2 3 3 3 5 2 3 5 2 3 5 2 3 5 2 3 Final Exam 63 26 36 tools and work pieces fixtures cutting time calculation non traditional cutting process metal forming: mechanical behaviour of metalssheet metal forming, forming processes forging types, planning, extrusion, types of drawing heat treatments for alloys, melting and phase change in alloys , Ferrous alloy heat treatment. Nonferrous alloy heat treatment 15 Teaching/Learning Method Lectures & Seminars Tutorials Computer lab Sessions Practical lab Work Reading Materials Web-site Searches Research & Reporting Problem Solving / Problem-based Learning Projects Independent Work Group Work Case Studies Presentations Simulation Analysis Selected Method Total Teaching Hours VII. Teaching and Learning Methods 3 5 Contact Hours Theoretical Practical Hours Hours* 2 2 3 Course ILOs Covered by Method (By ILO Code) K3,K8,K13 K3,K8,K13 Intellectual Skills I8,I18 I8,I18 Professional Skills P1,P2,P4 P1,P2,P4 General Skills Gc Gc K3,K8,K13 I8,I18 P1,P2,P4 Gc √ K3,K8,K13 I8,I18 P1,P2,P4 Gc √ K3,K8,K13 I8,I18 P1,P2,P4 Gc √ √ K&U Others (Specify): 3 The Higher Canadian Institute for Business and Engineering Technology Quality Assurance Unit Course Specification Selected Method VIII. Assessment Methods, Schedule and Grade Distribution Course ILOs Covered by Method (By ILO Code) Assessment Method K&U I.S. P.S. G.S. Midterm Exam Final Exam Quizzes Course Work Report Writing Case Study Analysis Oral Presentations Practical Group Project Individual Project Others (Specify): √ √ √ √ K3,K8,K13 K3,K8,K13 K3,K8,K13 K3,K8,K13 I8,I18 I8,I18 I8,I18 I8,I18 P1,P2,P4 P1,P2,P4 P1,P2,P4 P1,P2,P4 Gc Gc Gc Gc √ K3,K8,K13 I8,I18 P1,P2,P4 Gc √ K3,K8,K13 I8,I18 P1,P2,P4 Gc Assessment Weight / Percentage 20 50 5 10 5 Week No. 7 15 10 IX. List of References - Manufacturing Engineering and Technology, Schmid - Textbook ISBN #: 131489658 Course notes Powerpoint slides Recommended books Periodicals, Web sites, etc … Essential Text Books X. Facilities required for teaching and learning Data show, computer Course coordinator :Dr Ziad Ibrahim Head of Department: Dr Hamdy Hussein Date: September 2014 4