Fin Design for Maximum Thermal Dissipation

advertisement

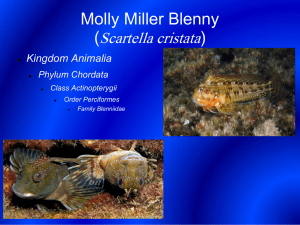

Fin Design for Maximum Thermal Dissipation ME 450: Computer Aided Engineering Analysis Instructor: Dr. Nema Group Members: Wei-Yuan Chu, Brad Holtsclaw, Nick Metzger, Breanne Walters Objectives Maximize Thermal Dissipation by Designing a Fin System that will Draw Heat Away from the Engine Casing Using Aluminum Alloy and Carbon Steel as Materials, we will analyze which material makes a better fin. Introduction Engine is used to run a small blower It is assumed that the motor casing will be subjected to cooling by a fan or other suitable ventilation. Main area of concern is drawing heat into the fin system in order to dissipate it into the air. Complete Assembly Area of Interest Theoretical Background E in E g E out E st dT dT dT q kT k (i j k ) dr d dz '' ; q '' h(T Ts ) Si Xj X l Sj X Xi l Theoretical Background (Cont.) NA f qt hAt 1 (1 f ) b At At NA f Ab A f 2 wLc Lc L f t 2 tanh mLc mLc cosh m( L x) (h / mk ) sinh m( L x) b cosh mL (h / mk ) sinh mL Model Details (Solid Modeling) Solid Models were created in Pro-Engineer and Converted to IGES Files to Import into Ansys Model Details (Type I) SOLID 92 Element Type 5,829 Elements 10,706 Nodes Model Details (Type II) SOLID 92 Element Type 16,196 Elements 29,355 Nodes Model Details (Type III) SOLID 92 Element Type 16,196 Elements 29,355 Nodes Boundary Conditions Temperature of 65.56oC applied to Internal Surface to Simulate Operating Conditions Boundary Conditions (Cont.) Ambient Temperature of 10oC Film Coefficient of 100 W/m*oC (for cooling airspeed of 10 m/s) Results and Discussion: S.S. Temperature Distribution (Type I) – Steel Top Fins Carbon Steel Top Fins Max. Temp. in Fins is 55.078oC Results and Discussion: S.S. Temperature Distribution (Type I) – Aluminum Top Fins Aluminum Top Fins Max. Temp. in Fins is 60.218oC Results and Discussion: S.S. Temperature Distribution (Type II) – Steel Top Fins Steel Top Fins Max. Temp. in Fins is 50.885oC Results and Discussion: S.S. Temperature Distribution (Type II) – Aluminum Top Fins Aluminum Top Fins Max. Temp. in Fins is 55.777oC Results and Discussion: S.S. Temperature Distribution (Type III) – Steel Top and Side Fins Steel Top and Side Fins Max. Temp. in Fins is 50.885oC Results and Discussion: S.S. Temperature Distribution (Type III) – Aluminum Top and Side Fins Aluminum Top and Side Fins Max. Temp. in Fins is 55.777oC Results and Discussion: Transient Response (Type III) – Aluminum Top and Side Fins Results and Discussion: Top Fin Design Comparison Solutions Temperature Distribution (Top Fins) Aluminum 1.2 Steel 1 θ/θb 0.8 0.6 0.4 0.2 0 0 0.01 0.02 0.03 0.04 0.05 Length (m) Steel Top Fins Length (m) thickness (m) width (m) 0.019 0.002 0.210 Af Ab At 0.008 0.013 0.064 Aluminum Top Fins Length (m) thickness (m) width (m) 0.019 0.002 0.210 Af Ab At 0.008 0.013 0.064 Lc t 0.020 m P 0.002 nf 43.644 Lc 0.800 t 0.020 m P 0.002 nf 20.015 0.900 h k 100.000 53.000 θb qt 0.632 55.410 651.498 0.423 h k 100.000 252.000 θb qt 0.290 55.410 679.434 0.423 Results and Discussion: Side Fin Design Comparison Solutions Temperature Distribution (Side Fins) Aluminum 1.2 Steel 1 t/tb 0.8 0.6 0.4 0.2 0 0 0.01 0.02 0.03 0.04 0.05 Length (m) Steel Side Fins Length (m) thickness (m) width (m) 0.051 0.004 0.229 Af Ab At 0.024 0.010 0.083 Aluminum Side Fins Length (m) thickness (m) width (m) 0.051 0.004 0.229 Af Ab At 0.024 0.010 0.083 Lc t 0.053 m P 0.004 nf 30.959 Lc 0.580 t 0.053 m P 0.004 nf 14.198 0.850 h k 100.000 53.000 θb qt 1.173 55.410 583.892 0.465 h k 100.000 252.000 θb qt 0.538 55.410 801.786 0.465 Results and Discussion: Heat Transfer Comparison for Type III Design Total Heat Transferred by Aluminum Fins Top Fins (W) 679.434 Side Fins (W) 801.786 Total (W) 1481.220 Total Heat Transferred by Steel Fins Top Fins (W) 651.498 Side Fins (W) 583.892 Total (W) 1235.390 Δq (W) 245.830 Impact Statements The Addition of Fins will Aid in the Heat Dissipation from the Motor Casing, making the Part More Safe for General Use Motor Casing with Type III Fins Will have a Reduced Surface Temperature and Less of a Chance of Overheating the Interior Electronics and Causing a Fire Conclusions Total Heat Transferred from Aluminum Fin is 245.83 W Greater than that from the Steel Fin. Efficiency for Aluminum Fin is Greater than that of Steel. Aluminum is the Best Choice for the Fin Material. References Nematollahi, Khosrow. "Oncourse, ME 450." Scheduled Reading and Assignments. IUPUI. 23 Apr 2007 <https://oncourse.iu.edu/access/content/user/knematol/Filemanager_Public_Fil es/ME450LectureNotesCh13r>. Incropera, Frank, David Dewitt, and Theodore Bergman. Fundamentals of Heat and Mass Transfer. 6th. Hoboken NJ: Wilet & Sons, 2007. Rengifo, Gustavo. "Oncourse, ME 546." ME 546 Resources, Project #1. IUPUI. 23 Apr 2007 <https://oncourse.iu.edu/access/content/group/SP07-IN-ME-54626532/Lab%20Projects/Project%>. Questions