Design for Stampings - University of Detroit Mercy

advertisement

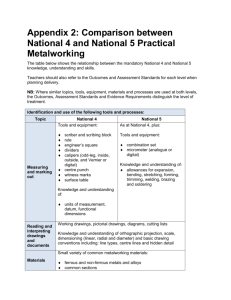

Design for Stamping Terry Sizemore University of Detroit-Mercy MPD Cohort 5 References Eary and Reed: Techniques of Pressworking Sheet Metal, 2nd ed. Prentice Hall Boothroyd, Dewhurst, Knight: Product Design for Manufacture and Assembly, 2nd ed. Marcel Decker Brallia: Design for Manufacturability Handbook, 2nd ed., McGraw Hill Sizemore: EMU MFG 316 Lecture Notes Ulrich and Eppenger Design for Stamping (DFS) Assumptions DFS will be “Design for Stamping” in this lecture DFS applies to sheet materials from .035 to .1875 Successful use of DFS is measured by: Improvement in quality by decreasing Quality Loss (Taguchi’s quality loss function) $$$’s of Die Cost Avoidance Number of processes eliminated Number reduced parts due to adding “Free” features Number of re-orientations eliminated Product Development Process Ulrich and Eppenger, 1995 Mission Statement Design for Stamping Concept Development System Design Detail Design Testing/ Refinement Production Ramp up Product Launch Agenda Cutting Properties of Metals (stress strain curve, spring back, etc) Forming Theory of Cutting Sheet Metal Forces for Cutting Die Cutting Operations Bending Embossing and Miscellaneous Forming Drawing Tooling Design Practices Agenda Cutting Properties of Metals (stress strain curve, spring back, etc) Forming Theory of Cutting Sheet Metal Forces for Cutting Die Cutting Operations Bending Embossing and Miscellaneous Forming Drawing Tooling Design Practices Theory of Cutting Assumptions Theory of Cutting also applies to the trimming of forgings, extrusions and castings and the cutting of bar stock Sheet metal is anything <.125, Plate is anything >.125 These rules do not apply to very brittle materials such as magnesium Analysis of Cutting Forces applied by the punch and die are shearing forces, which apply a shearing stress to the material until fracture Material deformation occurs in the plane of shear As the tool wears and the clearance between the punch and die grow the material will begin to experience more tensile deformation and less shear deformation prior to fracture (insert figures from pg 3) Characteristics of a Die Cut Edge Roll Over – Flow of material around the punch and die The larger the clearance the greater the roll over Burnish – The rubbed or “cut” portion of the edge The sharper the punch the wider the burnish Fracture – The angled surface where the material separates from the parent material Burr – The very sharp projection caused by a dull cutting on the punch or die. General Rules: The more dull the tool the greater the burr. The softer the material the greater the burr. *These characteristics are evident on both the hole and slug Penetration Roll Over + Burnish = Penetration Percent Penetrations Material Silicon Steel Aluminum % Penetration 30 60 .10 C Steel Annealed .10 C Steel Cold Rolled .20 C Steel Annealed .20 C Steel Cold Rolled .30 C Steel Annealed .30 C Cold Rolled 50 38 40 28 33 22 E.V. crane, Plastic Working in Presses, John Wiley and Sons, Inc., New York, 1948, p. 36 Die and Punch Clearance Proper Clearance Too Big – Blank ends up with rollover and/or a crown effect. Too Small – Results in large stripping force and secondary shear. Secondary shear is when the fracture propagating from the punch misses the fracture propagating from the die. When proper clearance exists the fractures meet, which yields a preferable break edge. Die and Punch Clearance Force Curves – Using strain gages or other transducers to create force vs. displacement curves is a common tool for analyzing various clearance conditions. Poor clearance conditions result in less than ideal force curves (may put in curves???) Other Characteristics Dish Distortion Spacing Distortion – When holes are punched next to each other in sequence distortion in the circularity and position of the first hole will occur. If possible punch closely proximate holes simultaneously. See attached table for recommended design practices. (insert figure and chart from page 20) Forces for Cutting For Cutting: In general ferrous stamping materials, shear strength is 70-80% ultimate tensile strength Force=Shear Strength*Perimeter of Cut*Thickness When calculating tonnage required it is recommended that ultimate tensile strength be used instead of shear strength to compensate for die wear. Tonnage=(UTS*Perimeter*Thickness)/2000 Forces for Cutting Take caution in what number is used for shear strength or UTS. Consideration must be made for prior operations that may affect the material properties. Work Hardening Annealing or Tempering Other processes that affect the mechanical properties of the material Work and Energy In terms of metal cutting: Work=average force*distance Force: Since the force/displacement curve for cutting sheet metal is nearly rectangular use the maximum force prior to fracture as the average force Distance: The distance used in this calculation is percent penetration (see earlier slide) multiplied by material thickness. This calculation assumes no secondary shear, which will require additional energy during cutting. Example 10 inch diameter aluminum blank made from .032 inch 3003 aluminum (3003 UTS is 11000 psi) Force=(11000)(3.14)(10)(.032) =11053 lbs Tonnage=11053/2000=5.5 tons Work=(5.500)(.600)(.032)=.1056 inch tons* (Need to insert penetration chart page 10) *Most press flywheels are rated in inch ton capacity Cutting Operations Blanking – Material removed is the work-piece Piercing – Material removed is scrap Lancing – No metal removed, bending and cutting Cut-off/Parting- Separating parts or reducing scrap strip size Notching – Removing material from the outer edges of the strip Shaving – Removing the break edge Trimming – Removing “Flash” from drawn parts Blanking Piercing Lancing Cut-Off/Parting Notching Shaving Trimming Agenda Cutting Properties of Metals (stress strain curve, spring back, etc) Forming Theory of Cutting Sheet Metal Forces for Cutting Die Cutting Operations Bending Embossing and Miscellaneous Forming Drawing Tooling Design Practices Stress/Strain Curves Insert Curve with details Geology of Stress Strain Curve Elastic Region Yield Point Necking Region Ultimate Point Elongation Spring Back Spring Back Agenda Cutting Properties of Metals (stress strain curve, spring back, etc) Forming Theory of Cutting Sheet Metal Forces for Cutting Die Cutting Operations Bending Embossing and Miscellaneous Forming Drawing Tooling Design Practices Forming Limit Diagram Bending Embossing Drawing Hydro-forming Agenda Cutting Properties of Metals (stress strain curve, spring back, etc) Forming Theory of Cutting Sheet Metal Forces for Cutting Die Cutting Operations Bending Embossing and Miscellaneous Forming Drawing Tooling Design Practices Transfer Dies Most automotive stampings created by transfer press Automation “transfers” part from die to die First picture shows stampings transferred from the side Second picture shows stampings transferred from the front and back Hydro-forming - Bladder press Create only bottom half of the die (cheaper and faster) Sheet metal placed over die Rubber-like material placed over sheet metal High pressure water forms part Progressive Dies Dies fed directly from steel coil No need for blanking operation Scrap get cut away as part gets formed Restricted to simple parts Flexible Forming Dies Rubber Pad Dies Tooling Materials Agenda Cutting Properties of Metals (stress strain curve, spring back, etc) Forming Theory of Cutting Sheet Metal Forces for Cutting Die Cutting Operations Bending Embossing and Miscellaneous Forming Drawing Tooling Design Practices Stamping Applications Can accommodate many functional features and attachment features Natural uniform wall thickness Can incorporate Springs Snap fit Tabs Spot welding Material Thickness from .001 in to .790 in Production 35 to 500 parts per minute 250000 per year minimum to justify using progressive die Progressive Die should eliminate at least two secondary operations before consideration Short run press tooling – Short run is when the cost of the tool exceeds the cost of the parts Punch presses should be used for low volume parts when possible Materials Any material that can be produced in sheet can be press-worked Deep drawn parts require “Draw Quality” steels Non-ferrous metals may require modified processing or additional processing steps Design Recommendations Shaping and nesting on strip Stamp multiple parts on same strip to increase strip utilization Design part/strip so part can be “cut-off ”, not “blanked” Holes Diameter not less then T, spacing should be 2T to 3T 1.5 to 2T between a hole and edge 1.5T + bending radius spacing between surface and hole Use pilot holes Design Recommendations Avoid sharp corners Improves tool wear Increases bur size Lowers stress Minimum radius of .5T or .03125 Be aware of grain direction Long sections should greater than 1.5T wide to avoid distortion and a weak problematic tool design Design Recommendations Use stiffening ribs or darts when more strength is needed Use extruded holes when threaded fasteners must be used (1.5 T is the max thread contact you can achieve) Set-outs – used for location, rivets, etc. Height to be .5T Be aware of the burr Dimensional Considerations Spring-back, die wear, material variation (temper, thickness, content) are sources of variation Short run prototype stampings should represent the dimensional population of the production tooled parts to prevent system failures when part goes into production