The business case for implementing machine vision

advertisement

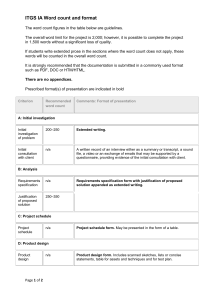

THE BUSINESS CASE FOR IMPLEMENTING MACHINE VISION Vision Systems International Established in 1984 Consultancy concentrating on machine vision Services include: Training Application related: Application engineering Specification writing Vendor identification/evaluation Market related Market research strategic development and planning partnering activities market analysis/competitive analysis due diligence Technology transfer Introduction Electronic Imaging Where is Machine Vision Used Why Machine Vision Now Machine Vision Industry/Market Compared to Human Vision Why Consider Machine Vision Applications Systematic Deployment What is Machine Vision Electronic Imaging vs.. Machine Vision Computers generating images CAD Animation Scientific Visualization GIS Computers operating on acquired images - Computer vision Security/surveillance Security/baggage handling Retail security Biometric/access control ATMs/OCR/security ITA/IVHS Biomedical/scientific/microscope Radiology - CAT/MRI/PET Automotive - autonomous vehicles Automotive aftermarket 2D symbology/bar code Document/form reading/OCR Machine Vision Where is Machine Vision Being Used Machine Vision is in use in virtually all manufacturing industries In some industries one can no longer produce without machine vision Why Machine Vision Now Technology Readiness Underlying technology for machine vision has evolved Components developed with features required to succeed in machine vision applications Lighting - LED - stable, long life Cameras - solid state, progressive scan, asynchronous scan, exposure control, color, high resolution Optics - telecentric, computer controlled zoom Compute power - PCs, DSPs, etc. Software - GUI - Windows - Standard PCI Interface, IEEE 1394 Technology Pull Quality emphasis (ISO 9000, 6 sigma, etc.) Productivity gains sought/downsizing eliminates eyes/requires substitute sensing Government regulations Machine Vision Industry/Market Not homogenous Segmented supply side GPMV/IPBS ASMV VAR demand side by industry process end package end applications that cut across industries e.g. web scanners GPMV Application Specific Modules PRINTING: INSPECTION, REGISTRATION CONTROL, COLOR CONTROL PHARMACEUTICAL: BLISTER PACK, VIAL/AMPULE, SOLID DOSAGES, OCR/OCV WELDING WEB PRODUCT OFF-LINE GAUGING MECH ASSY VERIFY CONSUMER PKG INSP FILLED CONTAINER: METAL, PLASTIC, GLASS, CLOSURES 2D LOCATION ANALYSIS ELEC. PKG. INSP: INSPECTION, QUALITY OF MARKINGS, CO-PLANARITY, BALL GRID ARRAY, OCR/OCV ELECTRICAL/ELECTRONIC CONN OCR/OCV 1D BAR CODES/2D BAR CODES/SYMBOLOGY EMPTY CAVITY INSPECTION COMPACT DISC APPLICATIONS CRT ELECTRONIC DISPLAYS DATA STORAGE Container Market Glass glassware manufacturer filler Can Plastic Closure For glass and can in late majority phase; for plastic in early adopter phase; for closure in early majority phase Pharmaceutical Market Process end Packaging end vials, filled/unfilled solid dosages label issues In process end in early adopter phase; in packaging in early/late majority phase Compared to Human Vision Machine vision does not compare well! We use 1011 neurons to perform about 1015 operations per second 2 billion years of evolutionary programming So Why Machine Vision? Humans only 70 85% effective! People Attention span/distractions Eye response Relative gauging Availability (breaks, vacations, sick, etc.) Consistency individual between individuals from day-to-day People Overload Boring Detect anomalies Adapt/make adjustments Interpret true nature of condition Machine Vision vs. People Speed Accuracy Repeatability Production Errors System Random Machine Vision vs. Human Vision Machine vision: best for quantitative measurement of structured scene Human vision: best for qualitative interpretation of complex unstructured scene Why machine vision works Because variables can be controlled parts can be presented consistently scene can be constrained MACHINE VISION Technology to improve quality reduce scrap/rework reduce cost improve productivity improve product reliability increase customer satisfaction increase market share Why Consider Machine Vision Technology to lower inventories avoid equipment breakdowns eliminate adding value to scrap avoid inspection bottlenecks yield consistent and predictable quality Machine Vision Applications Throughout a manufacturing facility incoming receiving forming operations assembly operations test packaging operations warehousing etc. Generic Applications Inspection 2D, 3D Metrology surface flaw/cosmetic analysis mechanical/electronic assembly verification location analysis visual servoing (2D and 3D) robot guidance pattern recognition character recognition part recognition 2D symbol reading Systematic Deployment Success Requires Senior management must foster atmosphere to encourage change support change agents demonstrate buy-in to change encourage plant and line to take ownership establish realistic schedule for changes Success is more likely People assigned are interested in new techniques and welcome change begin with easy, non-critical application define the parameters of the project and avoid creeping expectations select applications not critical to labor issues be supportive during learning process plan for replications Success is more likely Obtain people involvement Avoid technology leap that is too far Make certain project is part of an overall plan Implementation Process Assemble task force and study production process task force should develop understanding of what machine vision is define need and evaluate alternatives investigate - select specific applications assess technical feasibility and cost feasibility write comprehensive specification Implementation Process Install and run-in. Conduct acceptance test Provide shop floor support Evaluate system’s performance against goals Look for another machine vision opportunity Implementation Process Solicit 4 - 6 vendors with appropriate expertise Visit vendors to review proposals, policies, expertise, QC procedures Systematically select vendor Purchase Acceptance test at vendor Train all personnel Involved What is Machine Vision? As defined by the AIA: A system capable of acquiring one or more images, using an optical non-contact sensing device, capable of processing, analyzing and measuring various characteristics so decisions can be made. Relevance of Pixels 512 X 512 1300 X 1200 AP Wire Photo 35 mm color film Pixels 1/4M 1.4M 2.5M 20.0M Steps to Take When Buying a Machine Vision System Steps to Take When Buying a Machine Vision System Identifying Machine Vision Opportunities Assess Application Feasibility Understand the Application Understand the Vendors Responsive Proposals Systematic Buy-off Procedure Mistakes in Buying Automation Project Justification Identifying Machine Vision Opportunities Quality concerns Productivity/mechanization Process control Rework Inventory build-up - inspection bottleneck Equipment jams Warranty issues - field returns Employee turnover Identifying Machine Vision Opportunities Lowest value added Expensive fixturing Lengthy set up times 100% inspection required to sort bad parts Hazardous environment Contaminants Capital expansion Operator limitations Profile of Good Machine Vision Opportunity Perceived value Cost justifiable Recurring concern Can do something about it Straight forward Technically feasible Profile of Good Machine Vision Opportunity User friendly potential Dedicated line Long line life Operation champion Management commitment Global Competition Requires Higher manufacturing productivity Increased demand Higher product quality Better customer service Flexible manufacturing Greater return on manufacturing assets Changing standards of manufacturing performance Computer Aided Inspection Provides traceability - records Statistical data base - isolate production problems Real time machine correction/adaptive control Automatic QC data collection and analysis Remove drudgery of humans Hidden Costs Machine Vision Can Help Lost business because product not produced on time Shipment of wrong products Excess inventory Idle labor because parts are not available Doing a job over Loss of valuable information Machine Vision and Factory Automation Data driven automation Machine vision = data ! Statistics Measurements Parts recognized Classification Types of defects Trend analysis Performance assessment Record keeping Process Control Successful Application Requires Comprehensive understanding of needs Proper application process Good equipment and performance specifications Comprehensive understanding of machine vision system capability Steps to Take When Buying a Machine Vision Machine Vision is in Widespread Use Best Justification is Process Control Infrastructure Resources: AIA and MVA How To Select Machine Vision Equipment Understand the technology Assess application feasibility Understand the application Understand the vendors Responsive proposals Systematic buy-off procedure Applications in pharmaceuticals Understand the technology Steps to Take When Buying a Machine Vision System Become Informed Conferences Books Bibliography Assess Application Feasibility Steps to Take When Buying a Machine Vision System Assess Feasibility Basis rests with size of a pixel/FOV MVA slide rule Typical system handles 500 pixels Function of generic application: verification gauging part location flaw detection OCR/OCV/pattern recognition Verification Function of contrast - real or artificial high contrast - feature should cover 3 X 3 pixel area low contrast - feature should cover more pixels Gauging 500 marks on a ruler = resolution subpixel interpolation - factor of 4 to 10 requirements driven by tolerance rules of thumb: repeatability: 1/10th of tolerance accuracy: 1/10th to 1/20th of tolerance sum of accuracy + repeatability = 1/3 tolerance Gauging Discrimination - smallest change in dimension detectable with measuring instrument Discrimination = sub-pixel resolution Repeatability = +/- Discrimination Accuracy - determined by measurement of calibration standard = Discrimination Gauging - Example 2” part and 2” FOV tolerance: +/- 0.005”, total range 0.010” repeatability: 1/10 X 0.010” or 0.001” discrimination/accuracy: 1/20 X 0.010” or 0.0005” with 500 X 500 pixel camera, resolution = 0.004” with sub-pixel resolution 1/10, discrimination = 0.0004” = accuracy, so repeatability is = 0.0008” Part Location Analogous to gauging Can expect to achieve sub-pixel resolution: repeatability and accuracy Flaw Detection Contrast! Contrast! Contrast! Detection Vs. Classification Detection: High Contrast, normalized background (no pattern), can detect a flaw that covers 3 X 3 pixels Classification: flaw should cover 25 X 25 pixels OCR/OCV Stroke width - 3 pixels wide Character should cover 25 X 25 pixels Spacing between characters - 2 pixels Single font style - bold Result - 99.9% read rate effectiveness Linear Array Image Capture 2000 - 8000 pixels Scanning rates up to 2 - 20 KHz Speed should be well regulated Resolution in direction of travel function of speed and sampling rate of camera Understand the Application General Defect prevention is better than the cure! Study application site personally! Consider vision to enhance people! Expect productivity to decline! Steps to Take When Buying a Machine Vision System application issues: generic application variables: part, presentation, etc. material handling operator interface machine interfaces environmental issues system reliability/availability miscellaneous: documentation, warranty, training, software, spares, service acceptance test/buy off procedure responsibilities Tools Job descriptions Present specifications Part drawings Floor space drawings Samples Photos/videos Personnel Steps to Take When Buying a Machine Vision System Write functional specification Use “Machine Vision Requirements Checklist” - available from MVA - forces examination of: production process justification issues application issues System Spec Defines “what” system is and “how” system will work involves examination of implementation details programming standards style control methods System Specification The spec is not what the customer wants! Creeping expectations! Variables - Gotchas! System Specification Adhere to factory standards Adhere to engineering standards Use conventional jargon for part descriptions and to describe the process Use existing frames of reference to develop acceptance test Before RFP Prepare preliminary conceptual design Develop schedule - be realistic Assess cost Determine technical and cost feasibility Developing Functional Requirements What does the system do? What specific function do you want the MV value adder to do? What goals do you expect to achieve with MV? Will the MV system be for a retrofit or next generation product? Developing Functional Requirements Defines “what” system is and “how” system will work involves examination of implementation details programming standards style control methods Developing Functional Requirements Does the application involve: One object at a time Multiple objects How many different objects What are the part numbers? Is it a batch operation or continuous dedicated process? What are the changeover times and frequency of changeovers? Developing Functional Requirements What are the skill levels involved in changeover? How is function currently being performed? Can new variations to the part be expected? What might they be? Where do parts come from? What is material handling surrounding MV? Developing Functional Requirements Can rejected parts be repaired? Where do pass and fail objects go? When does the project have to be completed? How many shifts is the equipment used? If machine vision fails, what is the option? Developing Functional Requirements How many MV systems will be required annually? What are the consequences of a failed MV sequence? What are the consequences of a false reject? Developing Functional Requirements Describe the application Generically, does the application involve Gauging Assembly verification Flaw inspection Pattern recognition Developing Functional Requirements If Gauging What are the tightest tolerances? What is the accuracy design goal? What is the repeatability design goal? Are there reference features? What are calibration requirements? Developing Functional Requirements If assembly verification Dimensions of assembly Is it presence/absence Orientation verification What is the smallest piece to be verified and dimensions of that piece? Is part correctness also required? Developing Functional Requirements If flaw inspection Describe flaw types What is the smallest size flaw? Does the flaw affect surface geometry? Does the flaw affect surface reflectance? Is it more of a stain? Is classification of flaws required? Developing Functional Requirements If location analysis What is the design goal for accuracy? For repeatability? What is the area over which the “find” is required? Will angular as well as translation correction be required? Will scale change? Describe calibration requirements Developing Functional Requirements If pattern recognition What is the size of the pattern? Describe difference between patterns? Is there a background pattern? Does pattern involve color? Geometry? Number of different patterns? Is objective to identify? To sort? Developing Functional Requirements If specifically OCR/OCV Fixed font? Variable font? What is font? What is the height of the characters? What is the stroke width? What is spacing between and around characters? How many characters in string? How many lines? Color of print? Describe background – color, “busyness” Developing Functional Requirements Object dealing with What is material? What is finish (texture) like? Dull, glossy, specular? Is surface finish the same on all surfaces? For all part numbers? Production runs? Any platings, coatings, films, paints? Markings? Developing Functional Requirements Object dealing with – Shapes – flat, curved, gently curved, other? Irregular, grooved, sharp radii, mixed geometric properties? Part orientation variation? Part sizes? Part colors? (hue, saturation, brightness) Part temperature? Developing Functional Requirements Object dealing with – Possibility of warping, shrinking, bending, etc? Any change in appearance over time? Any markings? General appearance variables? Sensitivity to light? Developing Functional Requirements Material handling Present handling or being considered? Production rates? Currently? Future? Parts static? Moving continuously? Speed? If indexed How long stationary? Total in-dwell-out time? Settling time? Acceleration? Developing Functional Requirements Material handling Maximum positional variations – translation, rotation? More than one stable state? Volume envelope for MV? Any restrictions or obstructions? What triggers action? What is result of MV? Developing Functional Requirements Operator interface Operators themselves (education, familiarity with machinery, electronics, computers, etc.) Operator interface requirements? Personnel access requirements? Enclosure requirements? Object display requirements? Image condition storage requirements? Developing Functional Requirements Operator interface Fail-safe operation? Program storage requirements? Data storage requirements? Power failure requirements? Reporting requirements? False reject and escape rates? Developing Functional Requirements Machine interfaces Alarms desired? Other machine integration? What event triggers MV action? How detected? How communicated to MV? Machine interfaces: part in position, sensor type, PLC, Ethernet, etc. Hierarchical interfaces anticipated? Developing Functional Requirements Environmental issues Factory – clean room? Air quality? Corrosive? Ambient lighting? Part conditions? Wash-down? Temperature? Humidity? Radiation? Shock & Vibration? Utilities available: power, air, water, vacuum? Developing Functional Requirements System availability/reliability Number of hours per week? Hours available for maintenance? Calibration procedures? Challenge procedures? MTBF? MTTR? Developing Functional Requirements Other issues Special paint? Installation? Warranty? Spare parts? Documentation? Training? Software ownership? Questions? Good RFP Describes project in detail Describes operation’s business Reviews why the project is being solicited Reviews schedule RFP Should Request Schedule Training Service Warranty Software ownership Documentation Installation support Steps to Take When Buying a Machine Vision System Identifying Vendors AIA - Directory MVA - Directory Opto*Sense database Vendor type: image processing board general purpose machine vision system application specific machine vision system system integrator Understand the Vendors Machine Vision Industry Image Processing Board Suppliers General Purpose Machine Vision suppliers Machine Vision Software Suppliers Smart Cameras Suppliers Application Specific Machine Vision Suppliers System Integrators OEM System Integrator Look for application competency industry competency technological competency professional competency technology independence schedule/cost System Integrator Questions to ask: Have you done anything like this before? What do other clients think of you? Do you understand my requirements? Are your skills consistent with my requirements? Need a Consultant? Time an issue and corporate resources are lean Consultant can: write specifications write bid package identify vendors evaluate proposals prepare acceptance test plans Need a Consultant? Consultants conserve resources bring technology knowledge bring vendor knowledge bring objective counsel bring negotiating prowess Steps to Take When Buying a Machine Vision System Evaluate vendors systematically Use Decision Matrix technique to assess proposals Visit the 2 - 3 “best” vendors to assess: application engineering skills quality control procedures software practices training materials documentation policies references Responsive Proposals Proposals Should Include Review of implications of variables: staging image processing image analysis Implication of organization/lack of organization of parts Time budget to demonstrate confidence throughput can be met Proposals Should Include Position/temperature error budgets Interfacing issues: people machine/line Miscellaneous issues: enclosures battery back up diagnostics reports start up/changeover maintenance calibration Proposals Should Include Exceptions to the spec Responsibilities: installation specifically what is required for system to be successful Acceptance testing validation procedure challenge set Proposals Should Include Policy review training installation warranty field service spares software upgrades documentation Proposals Should Include Schedule Cost Proposals Should Reflect Familiarity with processes Grasp of problem Completeness and thoroughness Responsiveness Evidence of good organization and management practices Qualifications of personnel Proposals Should Reflect Experience in similar or related field or application Record of past performance Project planning Technical data and documentation Geographic location Proposer Evaluations Assess staying power Technical resources Design philosophy Capital/human resources Physical facilities Documentation Policies Proposer Evaluations Schedules References Quality control practices Vendor skills: optics TV Mechanical engineering Quality engineering Sizing up Vendors Differentiators How long before a service call is made or phone support is obtained Are software upgrades included in the price? Is upgrade notification automatic? What is the company’s annual sales revenue in the specific product/application Finalize Evaluations Make sure vendor understands Visit most responsive vendors Visit up and running installations Vendor Decision Previous work Quality of work Reputation Ability to meet schedule Understanding of your business and application Reference Checks Quality of work Ability to meet schedule Policies Support Would they do it over !!! Systems No system should be more complicated than it need to be! Good application engineering is critical! Contrast, Contrast, Contrast! Staging is important, if not more important than image processing algorithms! Customer Software and hardware should be transparent! Tinkering should be discouraged! Should not specify equipment, rather function! Samples furnished should be representative of all variables expected! Training is critical! A little knowledge is dangerous! Vision Company Room lighting is a No - No! Vision company should have all disciplines required! Beware of “Piece of cake!” Look for relevant experience! Verify quality practices! Verify policies: training, documentation, etc.! Systematic Buy-off Procedure Application Engineering Material handling Must avoid jamming regardless of deformities! Murphy’s Law - If it can go wrong, it will! Lighting Lighting is not a constant! Never use software to compensate for poor lighting! Shrouds are cheaper than software fixes! Application Engineering Optics There are limits to resolution! Nothing exceeds the speed of light! Image resolution Nyquist’s theorem does apply! More resolution means more compute power! A pixel is not a fixed size! - Magnification issues Steps to Take When Buying a Machine Vision System Write an acceptance test plan/buy-off procedure Different for: attribute inspection system - based on Thorndyke Chart to arrive at sample size - to test for both escapes and false rejects gauging/location analysis - repeatability/accuracy performance at upper limit, nominal and lower limit of tolerance Acceptance Testing Includes evaluation of operator interface basic operation calibration accuracy & repeatability throughput sensitivity maintainability availability Acceptance Testing Test at system level Test at other than nominal Test failure modes Test everything in system spec Don’t put anything into spec that can not be tested!!! Buy-off at Supplier Simulate external equipment Generate reports Run through all screen functions Simulate alarms and failure modes Power up/down system and components Steps to Take When Buying a Machine Vision System Using the Thorndyke chart from chart np - 3.0 e.g.. for 0 defects 95% confidence 400 PPM (reliability) n = 3/400 x 10 n = 7,500 -6 for every factor: color, finish, size, etc. Steps to Take When Buying a Machine Vision System Create a challenge to verify performance Working With The System In The Factory Should not deteriorate production speed! Ideally, avoid having to re-engineer the manufacturing process to accommodate machine vision! System should have the capacity to be reconfigured! Training Basic principles of operation Normal operating procedures screen functions power up/down reports Alarm conditions and recovery procedures Training Back-up procedures Normal and emergency maintenance Calibration Mistakes in Buying Automation Mistakes in Buying Automation 1. No equipment specification 2. Requesting quotes before visiting prospective suppliers 3. Incorrect cost estimate 4. Insufficient in-house machine support 5. No input from production people Mistakes in Buying Automation 6. Poor communication with vendor 7. Acceptance of inadequate equipment 8. Failure to supply latest drawings and parts with specifications 9. Failure to design for automation 10. Using the wrong technology per E. Martin, Lanco/NuTec, Assembly March 96 Reasons Why Automation Fails Per Automation Research Corp. Study Unclear or false expectations regarding what is to take place and the results that are to be achieved Lack of commitment by user management Over dependence on technical solutions Reasons Why Automation Fails Lack of acceptance by the user organization Poor project management Not properly taking into account the human resources issues SI Difficulties With Users Inadequate specifications Lack of technical knowledge No management commitment Internal policies Separating needs from wants Inability to take over system Changes in midstream SI Difficulties With Users No one person in charge Tight project constraints Lack of communication Price constraints Inability to take risks Manpower shortages Rigid specifications Project Justification Benefits of Machine Vision Scrap reduction Scrap disposal costs Rework Inventory reduction associated with rework Avoiding value added Improving machine uptime - capital productivity Avoiding return and warranty costs Improving customer satisfaction Project Justification Tangible benefits: increase productivity reduce scrap reduce rework time/inventory avoid adding value to scrap avoid product returns - warranty issues avoid liability issues avoid field service Project Justification Tangible benefits: avoid freight costs on returns avoid equipment breakdowns/improve machine uptime improve product fabrication cycle and impact on inventory save indirect labor cost save floor space to store rework inventory Project Justification Tangible benefits: training/labor/turnover/recruiting costs out of cycle costs due to schedule upsets waste disposal costs costs of overruns to compensate for yield personnel/payroll costs per employee: average worker’s compensation average educational grant per employee tooling/fixturing savings Project Justification Intangible benefits improve quality - consistency of quality predictability of quality information automation flexibility people effectiveness/limitations sample inspection only monitors system errors, not random errors Project Justification Intangible benefits: process control environment consumer/government pressure “eyes” for automation expansion needs seasonality Project Justification Because some things appear to be intangible does not mean they have zero value !!! In final analysis, justification of technology is a management issue - not an accounting issue !!!! Project Justification Data required: How many pieces are produced per month per line? How many production lines make the piece? What is the current inspection time per piece? (minutes/piece) What is the inspection labor rate? ($/hr including benefits) Project Justification Data required: How many rejects per month (%)? What is the value of a reject - $ -? What is the value of the raw material in the piece - $ -? What percent of the rejects are reworked per month? What is the average rework time/piece (minutes/piece)? Project Justification Data required: What is the monthly warranty cost - $? includes costs of field service, field returns, repairs, shipments to and from plant, paperwork, etc. Product liability costs per month - $? includes liability claims, lawyer fees, insurance, paperwork, etc. Project Justification Data required: What percent of the rejects are scrapped per month? - the difference between the number of rejects per month and the number of rejects reworked per month and returned to inventory What are the monthly waste disposal costs due to the scrapped pieces? Project Justification Data required: What are the scrap and rework inventory costs per month? - eg. Calculate based on average number of units scrapped and in inventory per month multiplied by the value (cost) of the piece divided by 10 (factor that assumes any such unit will only be in inventory an average of two days) How many shifts does the line operate? Project Justification Data required: Total hours operating per shift? Hours worked per month/shift/person? - paid hours Number of units sold per month? Average selling price of the piece? - not cost Indirect (supervisory) labor rate ($/hr with benefits)? What is the profit per piece produced? ($) Project Justification Data required: Current cost of money? Prime rate + 1%? If sample inspection, hours per month for specific piece? Project Justification Calculated values: annual direct cost of inspection per piece = inspection labor rate X hours worked per month/shift X number of shifts line operates X 12 annual indirect cost of inspection per piece = indirect labor rate X hours worked per month/shift/person X number of shifts X 12 Project Justification Calculated values: cost of rejects scrapped = percent rejects/ month X value of a reject X % pf rejects scrapped/ month X number of pieces produced/month X 12 cost of rework = percent of pieces reworked/month X number of pieces produced per month X rework time X rework labor rate X 12 Project Justification Calculated values: warranty costs = monthly warranty costs X 12 liability costs = monthly product liability costs X 12 scrap disposal costs = monthly cost X 12 scrap and rework inventory costs = monthly X 12 training costs - based on turnover experience Project Justification Assigning values: value of reliable data = sum of annual direct and indirect labor costs X 0.05 value of improved customer satisfaction = average selling price of the piece X number of units sold per month X 12 X 0.001 Project Justification Assigning values: percent uptime line improvement anticipated an estimated value value due to gain in line uptime = cost of machine vision system X number of systems required X 0.05 Project Justification Costs cost of machine vision system (or systems) launch costs (training, etc.) - estimate 10% of machine vision system costs annual service contract - estimate 10% of machine vision system costs Project Justification Costs: opportunity cost - function of the cost of money = cost of the machine vision system X number of systems + launch costs + annual service contract X number of systems X current cost of money Project Justification Costs: total equipment costs = cost of machine vision systems X number of systems + launch costs + annual service contracts X number of systems + opportunity cost average annual cost over four years = total equipment costs/4 Project Justification Return on investment = (average annual savings/total equipment costs) X 100 Payback (years) = total equipment costs/(average annual savings + average annual costs with machine vision) Average Payback Period by Company Size Per Automation Research Corp. large 2.85 medium 3.06 small 3.27 2.6 2.8 3 Years 3.2 3.4 Average Payback Period in Years by Industry Per Automation Research Corp. 2.8 2.4 3 2.8 2.3 2 1 ry hi ac m m fa b ne et al s cs ni tro ec el ec tri ca l el e ac sp ro ae to m ot ive 0 au Years 3.7 3.6 4