Process Costing - students of ca and cs

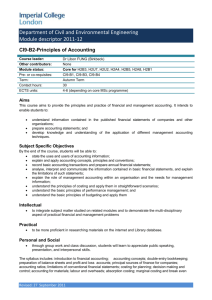

advertisement