Capacity strategy

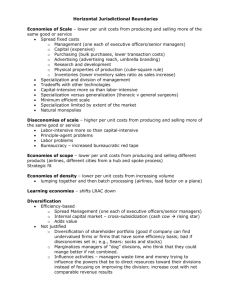

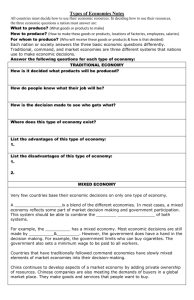

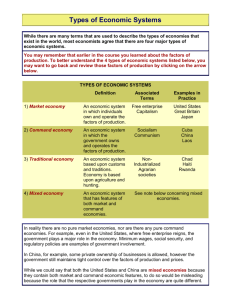

advertisement

Capacity strategy Some factors influencing the overall level of capacity Availability of capital Forecast level of demand Cost structure of capacity increment OPERATIONS RESOURCES Changes in future demand Overall level of MARKET capacity REQUIREMENTS Uncertainty of future demand Economies of scale Flexibility of capacity provisions Consequences of over/undersupply Capacity strategy issues include….. NUMBER OF SITES CAPACITY OF EACH SITE ALLOCATION OF TASKS TO EACH SITE LOCATION OF EACH SITE LONG-TERM CAPACITY CHANGE STRATEGY Importance of capacity strategy Capacity is regarded by some people as a particularly ‘dry’ subject. The reality is very different. Not only is the idea of capacity at the very heart of what operations management is about, the failure to get capacity decisions right in the long-term (or in the short-term for that matter) can be dramatic and sometimes disastrous. Not only that, but also there are always examples of capacity strategy in the press. News stories that look at location decisions, reducing capacity by reducing the number of jobs in a firm, being surprised by the volume of demand, getting forecasts hopelessly wrong and so on, can all be exploited to illustrate aspects of capacity strategy. Capacity can be considered as: Strategic capacity Strategic capacity (contd.) Strategic capacity (contd.) Strategic capacity (contd.) Questions NUMBER OF SITES and CAPACITY OF SITES LOCATION OF SITES Options Many small sites? Few larger sites? Supply side dominated? Demand side dominated? ALLOCATION OF TASKS TO SITES All sites make all products/services? LONG-TERM CAPACITY CHANGE STRATEGY Capacity leads demand? Each site focuses on a few products/ services? Capacity lags demand? Why is capacity strategy important? Without an appropriate capacity strategy, operations will always be struggling to supply markets in a competitive manner Getting capacity strategy right is the starting point for developing competitive operations Why is capacity strategy important? Without an appropriate capacity strategy, operations will always be struggling to supply markets in a competitive manner Getting capacity strategy right is the starting point for developing competitive operations How should one judge a capacity strategy ? NUMBER OF SITES CAPACITY OF EACH SITE ALLOCATION OF TASKS TO SITES Costs LOCATION OF EACH SITE LONG-TERM CAPACITY CHANGE STRATEGY What performance measures will all these decisions have a major impact on? Revenues Cash requirements Service levels The 4 V’s of capacity Three levels of capacity decisions Key points in capacity strategy How we manage capacity in the longer term is influenced by both market and operations resource factors. The idea of the break-even point is hugely important. Profitability and volume are not always related in a straightforward manner. The idea of economies of scale and diseconomies of scale apply to all types of operations. In particular, diseconomies of scale are a function of customer perception as well as straightforward cost implications of scale. Various decisions that make up a capacity strategy are interrelated. In particular, the idea of how many sites, how big each site should be, whether it should be specialist or generalist and its location, are all connected. Key points in capacity strategy The dynamics of capacity change are as important as a static analysis. As volume changes, capacity must also change. Making changes that are too early, too late or of the wrong magnitude can all have serious consequences. Location is becoming a particularly important decision. The economies of location in many industries are changing fundamentally. Easier communication and globalised industries mean that the number of location options available is now often very great. Some factors influencing the number and size of sites Economies of scale Required service level OPERATIONS RESOURCES Supply costs Size and number MARKET of sites REQUIREMENTS Geographical distribution of demand Different approaches to location are taken by different types of business Cost, volume, profit illustration 12 Costs / Revenue ($) 10 8 Cost 6 4 Revenue 2 0 0 2 4 6 Volume in thousands of units 8 10 12 Forecast demand = 9,000 units Unit cost curve Unit cost (total cost / volume) (a) 8 6 Nominal capacity limit 4 2 0 0 1 2 4 3 Volume in thousands of units 5 6 Unit cost curve Unit cost (total cost/volume) (b) 8 6 Diseconomies of scale kick in 4 2 0 0 1 2 4 3 Volume in thousands of units 5 6 Economies of scale Generally, the cost (Cy) of providing capacity in one increment of size y is given by Cy = Kyk, Where K is a constant scale factor and k is a factor which indicates the degree of economies of scale for the technology involved (usually between 0.5 and 1.0) Exploiting economies of scale When Ford took over the car-making division of Sweden’s Volvo for $6.45 billion, it made relatively little difference to Ford’s overall size. Volvo’s modest output of less than 400,000 cars per year was tiny by world standards. Yet the effect on Volvo’s ability to compete was significant. Even in the short term, cost savings could come from tapping into Ford’s logistics and purchasing functions. Ford’s logistics network in the USA could easily cope with Volvo’s products and the United States was Volvo’s biggest market. Similarly with purchasing: although Volvo had its own platform designs, even in the short term, it could substitute some of Ford’s components which it bought from specialist suppliers. Changes in demand Long-term demand lower than shortterm demand Short-term demand lower than long-term demand Decision varies with circumstances Expanding physical capacity in advance of effective capacity can bring greater returns in the longer term Physical capacity of facilities Demand Effective capacity Time Expanding physical capacity in advance of effective capacity can bring greater returns in the longer term Cash flow with extended physical capacity Cash flow with two identical capacity increments Time Some factors influencing the location of sites Resource costs Required service level Land and facilities investment Suitability of site OPERATIONS RESOURCES Location of sites MARKET REQUIREMENTS Image of location Resource availability Community factors Location decisions We could try contrasting the different approaches to location taken by different types of business. For example, we could compare the location decision facing a company wishing to build a new factory in a region, with a fast-food restaurant looking for a location in a town where it has no existing outlets. The idea here is to contrast two very different types of location decision. The new factory location The new factory location would follow the ideas as set out in the chapter. These tend to assume that location is being chosen primarily on the grounds of minimizing the costs associated with the site. The amount of products sold by the company is unlikely to be very much affected by its location, but its costs could be very much affected by location factors. Furthermore, there are likely to be a very large number of sites that the company could choose from. The fast food restaurant The fast-food restaurant, on the other hand, involves a different sort of location decision. Both revenue and costs will be affected by the location. Locating the restaurant away from other restaurants and/or away from passing trade is likely to mean a reduction in revenue. Some locations are better than others at attracting customers. Also, the costs of the location (such as rent, rates etc.) are affected by location. Finally, there are rarely a large number of options to choose the location from. Usually location is more opportunistic. The fast-food restaurant might wait until a site becomes available and then take the decision as to whether to have that site or to wait in case a better one becomes available. The cost breakdown of a shirt made in various countries and sold in France 15.55€ France 14.33€ Portugal Turkey 11.43€ Thailand 11.43€ Labour 11.13€ Morocco Transport 10.82€ Romania China Fabric 10.37€ Supplies Customs duties 9.60€ Myanmar 0 2 4 8 6 Cost in euros 10 12 14 16 Source: Slack, N., Chambers, S. and Johnston, R. (2007) Operations Management, 5th edn. Harlo Some factors influencing the timing of capacity change Lead-time of capacity change Ability to cope with change Forecast level of demand Competitor activity OPERATIONS RESOURCES Overall level of MARKET capacity REQUIREMENTS Uncertainty of future demand Economies of scale Required level of service 2,400 Volume (Units / week) 2,000 Capacity plans for meeting demand using either 800- or 400-unit capacity plan using plants Capacity 800-unit plants Capacity plan using 400-unit plants Demand 1,600 1,200 800 400 Time Smaller-scale capacity increments allow the capacity plan to be adjusted to accommodate changes in plan using demandCapacity 800-unit plants 2,400 Volume (Units/week) 2,000 Capacity plan using 400-unit plants Forecast demand Actual demand 1,600 1,200 800 400 Time Rarely does each stage of a supply chain have perfectly balanced capacity because of different optimum capacity increments Current capacity = 1,010 units Current capacity = 1,000 units Current capacity = 900 units Current capacity = 1,100 units Required new capacity = 1,800 units Required new capacity = 1,800 units Required new capacity = 1,800 units Required new capacity = 1,800 units Capacity increment 800 units Capacity increment 600 units Capacity increment Operating cost Distribution Operating cost Warehouse Operating cost Assembly plant Operating cost Parts manufacture Capacity increment Cost, volume, profit illustration Costs / Revenue ($) 10 8 Cost 6 4 Revenue 2 0 0 2 4 6 8 Volume in thousands of units Forecast demand = 9,000 units 12 10 12 Strategies for expanding long-term capacity The three options ….. Demand Capacity Time Time Demand Capacity Time Demand Capacity Time The advantages and disadvantages of pure leading, pure lagging and smoothing with inventories strategies of capacity timing Capacity-leading strategy Capacity-lagging strategy Smoothing-with-inventories strategy Output Capacity planning with certain forecasts and capacity introduction Planned capacity Forecast demand Time Capacity increment 1 Capacity increment 2 Capacity increment 3 Capacity increment 4 Decision tree for simple capacity expansion example $10m A $3m $5m B $5m Decision tree for two-year analysis $32m $18m C $24m $24m A $15m $8m D $17m $9m $18m $18m E $8m $8m B $18m $14m F $8m $8m