Professor's Slides: Flexible Manufacturing Systems

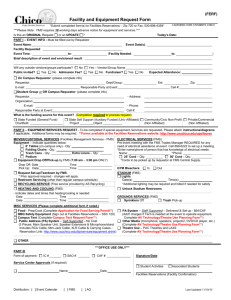

advertisement

MODELING AND ANALYSIS OF MANUFACTURING SYSTEMS Session 7 FLEXIBLE MANUFACTURING SYSTEMS E. Gutierrez-Miravete Spring 2001 DEFINITION A FLEXIBLE MANUFACTURING SYSTEM (FMS) IS A SET OF NUMERICALLY CONTROLLED MACHINE TOOLS AND SUPPORTING WORKSTATIONS CONNECTED BY AN AUTOMATED MATERIAL HANDLING SYSTEM AND CONTROLLED BY A CENTRAL COMPUTER ELEMENTS OF FMS • AUTOMATICALLY REPROGRAMMABLE MACHINES. • AUTOMATED TOOL DELIVERY AND CHANGING • AUTOMATED MATERIAL HANDLING • COORDINATED CONTROL FMS FEATURES • MANY PART TYPES CAN BE LOADED • PARTS CAN ARRIVE AT MACHINES IN ANY SEQUENCE • PARTS IDENTIFIED BY CODES • MANY MACHINES CAN BE INCLUDED • SMALL FMS LEAD TO FLEXIBLE CELLS FMS FEATURES • EXPENSIVE TO IMPLEMENT BUT SAVINGS CAN BE SIGNIFICANT • FLOOR SPACE REDUCIBLE BY 1/3 • EQUIPMENT UTILIZATION UP TO 85% OR MORE • DETAILED PRODUCTION SEQUENCE NOT NEEDED WELL IN ADVANCE FMS FEATURES • REDUCED VARIABLE COSTS AND THROUGHPUT TIME LEAD TO ENHANCED MANUFACTURING COMPETITIVENESS • ELIMINATION OF STARTUP CYCLES LEAD TO STANDARIZED PERFORMANCE • MODULAR DESIGN FMS FEATURES • • • • REDUCED DIRECT LABOR COSTS THREE SHIFTS READILY FEASIBLE IDEAL FOR JIT CAN EASILY BE TURNED OVER TO NEW SET OF PRODUCTS IF THE NEED ARISES MANUFACTURING FLEXIBILITY • BASIC – MACHINE (VARIETY OF OPERATIONS) – MATERIAL HANDLING (PART MOBILITY AND PLACEMENT) – OPERATION (VARIETY OF OPERATIONS PRODUCING SAME PART FEATURES) MANUFACTURING FLEXIBILITY • SYSTEM – PROCESS (VARIETY OF PARTS PRODUCIBLE WITH SAME SETUP) – ROUTING (ABILITY TO USE DIFFERENT MACHINES UNDER SAME SETUP) – PRODUCT (CHANGEOVER) – VOLUME (PRODUCTION LEVEL) – EXPANSION (ADDED CAPACITY) MANUFACTURING FLEXIBILITY • AGGREGATED – PROGRAM (UNATTENDED RUNNING) – PRODUCTION (RANGES OF PARTS, PRODUCTS, PROCESSES, VOLUME, EXPANSION) – MARKET (COMBINATION OF PRODUCT, PROCESS, VOLUME AND EXPANSION) COMMENTS DOES FLEXIBILITY REMOVE VARIABILITY FROM THE SYSTEM? NO, BUT IT ENABLES IT TO PERFORM EFFECTIVELY COMMENTS KEY ISSUE CAN A SYSTEM BE DESIGNED WHICH IS USEFUL OVER A SUFFICIENT TIME HORIZON, PART MIX AND SMALL CHANGEOVER TIMES SO AS TO OFFER AN ALTERNATIVE TO SIMULTANEOUS PRODUCTION OF MEDIUM VOLUME PART TYPES? COMMENTS THE PART TYPES ASSIGNED TO THE FMS SHOULD HAVE SUFFICIENT PRODUCTION VOLUMES TO MAKE AUTOMATION ATTRACTIVE BUT INSUFFICIENT TO JUSTIFY DEDICATED PRODUCTION LINES ORIGINS OF FMS • LINK LINES (1960’S) • NC MACHINES AND CONVEYORS • BATCH PROCESSING ACRONYMS • • • • • • FMS NC DNC CNC AGV JIT FMS PRIORITIES • MEETING DUE DATES • MAXIMIZING MACHINE UTILIZATION • MINIMIZE THROUGHPUT TIMES • MINIMIZE WIP LEVELS FMS COMPONENTS • • • • MACHINES PART MOVEMENT SYSTEMS SUPPORTING WORKSTATIONS SYSTEM CONTROLLER MACHINES • PRISMATIC VS ROTATIONAL PARTS • HORIZONTAL MACHINING CENTERS (HMC) AND HEAD INDEXERS (HI) • TOOL MAGAZINES AND AUTOMATIC TOOL CHANGERS PART MOVEMENT • CONVEYORS • TOW CARTS • RAIL CARTS • AGV’S SUPPORTING WORKSTATIONS • LOAD/UNLOAD STATIONS • AUTOMATIC PART WASHERS • COORDINATE MEASURING MACHINES CONTROLLER • COMPUTER • WORKER (ATTENDANT) • TRACKING SYSTEM FOR – PARTS – MACHINES PLANNING AND CONTROL HIERARCHY DECISION MAKING PROCESS – WHICH INFORMATION SHOULD BE COMMUNICATED? – HOW DO SYSTEM COMPONENTS COMMUNICATE? COMPONENTS OF THE MANUFACTURING FACILITY – FACILITY – SHOP – CELL – WORKSTATION – EQUIPMENT MULTILEVEL CONTROL HIERARCHY • TREE STRUCTURE OF THE HIERARCHY • INFORMATION FLOWS ONLY BETWEEN ADJACENT LAYERS • EACH LEVEL HAS ITS OWN PLANNING HORIZON AND DECISION TYPES • Fig. 5.5 and Table 5.1 , p. 133 GENERIC CONTROL MODEL • GENERIC CONTROL STRUCTURE USED TO ACCOMPLISH PLANNING, EXECUTION AND FEEDBACK • COMMANDS ARE RECEIVED FROM THE NEXT HIGHER LEVEL AND TASKS ARE BROKEN INTO SUBTASKS • SUBTASKS ARE ASSIGNED TO COMPONENTS AT NEXT LOWER LEVEL GENERIC CONTROL MODEL • SUBTASK MONITORING PERFORMED THROUGH RECEIPT OF STATUS FEEDBACK FROM LOWER LEVEL • TASK STATUS INFORMATION RELAYED TO NEXT HIGHER LEVEL • EACH CONTROLLER HAS A PRODUCTION MANAGER RECEIVING COMMANDS AND SCHEDULING TASKS GENERIC CONTROL MODEL • QUEUE MANAGER MAINTAINED FOR EACH LOWER LEVEL COMPONENTS TO MANAGE ASSIGNED SUBTASKS • DISPATCH MANAGER RECEIVES DISPATCH ORDERS AND MANAGES SUBTASK EXECUTION FOR EACH QUEUE MANAGER • Fig. 5.6, p. 134 BASIC STEPS IN DECISION HIERARCHY • LONG TERM PLANNING OR SYSTEM DESIGN (PART TYPES & EQUIPMENT SELECTION) • MEDIUM RANGE PLANNING OR SETUP (DAILY DECISIONS ABOUT PARTS & TOOLING) • SHORT TERM OPERATION (SCHEDULING & CONTROL) SYSTEM DESIGN • PROBLEM: SELECTING SYSTEM SIZE, HARDWARE, SOFTWARE AND PARTS FOR THE FMS • SIZE & SCOPE ARE SELECTED ACCORDING TO CORPORATE STRATEGY • HARDWARE & SOFTWARE SELECTED TO FIT SCOPE SYSTEM DESIGN • PART SELECTION IS DONE ACCORDING TO AN ECONOMIC CRITERION & STRATEGIC CONSIDERATIONS • KNAPSACK PROBLEM: LOAD THE FMS TO MAXIMIZE SAVINGS SUBJECT TO FMS CAPACITY KNAPSACK PROBLEM P = PRODUCTIVE TIME PER PERIOD AVAILABLE ON BOTTLENECK FMS RESOURCE pi = TIME PER PERIOD REQUIRED FOR PART i si = SAVINGS PER PERIOD IF PART TYPE i KNAPSACK PROBLEM maximize i si Xi subject to i p i < P SOLVING THE KNAPSACK PROBLEM • • • • GREEDY HEURISTIC Example 5.1, p. 136 OPTIMIZATION Example 5.2, p. 138 SYSTEM SETUP • ASSIGNMENT OF OPERATIONS AND ACCOMPANYING TOOLING TO MACHINES • PART SELECTION PROBLEM: BATCH FORMATION • LOADING PROBLEM: SEQUENCING AND ROUTING OF PARTS PART SELECTION • GOAL: PLACE REQUIRED PARTS INTO COMPATIBLE BATCHES SUCH THAT • EACH BATCH USES ALL MACHINES • REQUIRE A LIMITED NUMBER OF TOOLS ON EACH MACHINE • HAVE SIMILAR DUE DATES FOR PARTS IN THE BACTH PART SELECTION • GREEDY HEURISTIC: FORM BATCHES BY ARRANGING PART ORDERS BY DUE DATES • PART ORDERS ARE SEQUENTIALLY ADDED TO CURRENT BATCH WITHOUT VIOLATING CONSTRAINTS • BATCH IS THEN READY FOR LOADING • Example 5.3, p. 140 Part Selection as a Mixed-Integer Program • Time phased set of part orders Dit for part i in time t • Time available in machine j , Pj • Time required by product i in machine j pij • Number of parts of type i made in time t xit • Number of tool slots in machine j , Kj Part Selection as a Mixed-Integer Program • Number of tool slots required by tool l in machine j , klj • Set of tools l required on machine j to produce part i , l j(i) • Holding cost per period for part i hi • Formulation: p. 142 Part Selection as a Mixed-Integer Program • Goal: Minimize inventory cost while meeting due dates • Example 5.4 , p. 142 Incremental Part Selection • Several part types in process at any time • System operates almost continuously • Goal: Minimize makespan to complete all available part orders • Procedure: Minimize idle time by balancing work loads subject to part demand and tool magazine capacity • Formulation: p. 144 LOADING PROBLEM • BATCH TO BE PROCESSED IS KNOWN • OBJECTIVES REQUIRED • LOADING SOLUTION MUST BE ROBUST AND FLEXIBLE • SOLUTION METHODOLOGIES – MATHEMATICAL PROGRAMMING (p.145) – HEURISTIC APPROACHES (p. 148) LOADING PROBLEM: HEURISTIC APPROACH • PHASE I : ASSIGN OPERATIONS TO MACHINE TYPES • PHASE II: – OPERATIONS COMBINED INTO CLUSTERS TO REDUCE TRANSFERS – MACHINE GROUPS FORMED – OPERATIONS AND TOOLS ASSIGNED TO GROUPS SCHEDULING AND CONTROL • BASIC PROBLEM AREAS – SEQUENCING AND TIMING OF PART RELEASES TO THE SYSTEM – SETTING OF INTERNAL PRIORITIES IN THE SYSTEM – ABILITY OF SYSTEM TO TAKE CORRECTIVE ACTION WHEN COMPONENTS FAIL Flexible Assembly Systems • For the combination of raw materials and components into products with functional characteristics. • Automated vs manned systems • Example: Vibratory bowl feeders and vision systems • Role of Design for Assembly