(TIMET) Titanium in Chemical Process Industry (CPI)

advertisement

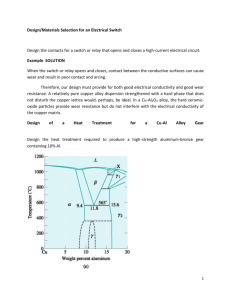

Titanium in Chemical Process Industry (CPI) Suresh Divi Corrosion Engineer Titanium Metals Corporation (TIMET) Process Corrosion Session NACE Eastern Area Conference Oct. 7, 2009 Outline •Introduction to the “CPI” •CPI Equipment/Components •Titanium Corrosion Resistance •Titanium alloys •Ti Applications in CPI •Benefits & Cost considerations •Ti role in the CPI •Summary Introduction to the “CPI” •An industry in which the raw materials undergo chemical conversion during their processing into finished products •Chemical conversion influences the pH of the product •Intern pH influences the corrosion resistance of the metal •Very aggressive conditions (low pH, high temperature) •In Petroleum refining, acidic conditions arise from chloride salts entering the refinery in crude oil •Dilute HCl acid encounter in many chlorination type chemical process.Example: Manufacturing of Vinyl chloride monomer(VCM) Typical CPI •Power Generation •Petrochemical •Organic acid •Chemical •Fertilizers •Metal Recovery •Salt •Chlorine •Pulp & paper CPI Equipment •Heat Exchangers •Reactor vessels •Piping •Pumps •Mixers •Anodes •Anode baskets •Distillation Columns Titanium • • • • • • Abundant - Not Exotic! 4th most plentiful metal on earth Classified as a reactive metal (passive oxide film) About half as dense as nickel Similar in strength to 316 S.S. (CP Ti) Excellent corrosion resistance/immunity in chlorides (especially sea water) • 45+ years service experience with the CPI Ti Corrosion Resistance •Corrosion protection is due to the formation of oxide film •Thin (100Å) and transparent •Stable and chemically resistant •Smooth and ceramic like, hard to remove •Instantaneously reheal after damage (needs traces of water or oxygen) Titanium Corrosion Resistance •Anodic Protection (external power supply) •Inhibitors (Fe+3, Cu+2, Mo+6,etc..) •Alloying with stable elements (Mo,Zr ,Cr) •Alloying with noble metals (Pt,Pd,Ru) •Very resistant to oxidizing media (HNO3) Titanium Corrosion Resistance Wide range of passivation Titanium Corrosion Resistance •Excellent resistance to chloride corrosion (pitting) •Immune to soil & atmospheric corrosion •No preferential weld corrosion •Immune to MIC (microbial influenced corrosion)attack •Good resistance to Erosion •No corrosion in Sea water Titanium alloys Titanium & Titanium Alloys for the CPI Market ASTM ASTM GRADE ASTM GRADE ASTM GRADE GRADE 1 1 1 2 1 2 27 27 16 7 16 7 16 3 16 3 3 12 3 12 12 9 12 9 9 32 9 32 32 5 32 5 5 23 5 23 23 23 TIMET TIMET DESIGNATION TIMET DESIGNATION TIMET DESIGNATION DESIGNATION TIMETAL@ 35A TIMETAL@ 35A TIMETAL@ 35A TIMETAL@ 35A 50A TIMETAL@ TIMETAL@ 50A TIMETAL@ 50A Pd TIMETAL@ 50A Pd 05Pd TIMETAL@ TIMETAL@ 50A 50A Pd 05Pd TIMETAL@ TIMETAL@ 50A 50A Pd 05Pd TIMETAL@ TIMETAL@ 65A 50A 05Pd TIMETAL@ 65A TIMETAL@ 65A TIMETAL@ TIMETAL@ CODE 65A 12 TIMETAL@ CODE 12 TIMETAL@ CODE 12 TIMETAL@ TIMETAL@ 3-2.5 CODE 12 TIMETAL@ 3-2.5 TIMETAL@ 3-2.5 TIMETAL@ TIMETAL@ 5111 3-2.5 TIMETAL@ 5111 TIMETAL@ 5111 TIMETAL@ TIMETAL@ 6-4 5111 TIMETAL@ 6-4 TIMETAL@ 6-4 TIMETAL@ 6-4 6-4 ELI TIMETAL@ TIMETAL@ 6-4 ELI TIMETAL@ 6-4 ELI TIMETAL@ 6-4 ELI NOMINAL NOMINAL COMPOSITION NOMINAL COMPOSITION NOMINAL COMPOSITION COMPOSITION Unalloyed Titanium Unalloyed Titanium Unalloyed Titanium Unalloyed Titanium Titanium Unalloyed Unalloyed Titanium Ti-0.15Pd Titanium Unalloyed Ti-0.15Pd Unalloyed Ti-0.05Pd Titanium Ti-0.15Pd Ti-0.05Pd Ti-0.15Pd Ti-0.05Pd Unalloyed Ti-0.05Pd Titanium Unalloyed Titanium Unalloyed Titanium Ti-0.3Mo-0.8Ni Unalloyed Titanium Ti-0.3Mo-0.8Ni Ti-0.3Mo-0.8Ni Ti-3Al-2.5V Ti-0.3Mo-0.8Ni Ti-3Al-2.5V Ti-5Al-1Sn-1Zr-1VTi-3Al-2.5V Ti-5Al-1Sn-1Zr-1V0.8Mo-0.1Si Ti-3Al-2.5V Ti-5Al-1Sn-1Zr-1V0.8Mo-0.1Si Ti-5Al-1Sn-1Zr-1V0.8Mo-0.1Si Ti-6Al-4V 0.8Mo-0.1Si Ti-6Al-4V Ti-6Al-4V Ti-6Al-4V-0.1O Ti-6Al-4V Ti-6Al-4V-0.1O Ti-6Al-4V-0.1O Ti-6Al-4V-0.1O UNS UNS DESIG. UNS DESIG. UNS DESIG. DESIG. R50250 R50250 R50250 R50400 R50250 R50400 R52400 R50400 R52400 R50400 R52402 R52400 R52402 R52400 R52402 R50550 R52402 R50550 R50550 R53400 R50550 R53400 R53400 R56320 R53400 R56320 R56320 R55111 R56320 R55111 R55111 R56400 R55111 R56400 R56400 R56407 R56400 R56407 R56407 R56407 ALLOY ALLOY TYPE ALLOY TYPE ALLOY TYPE TYPE Alpha Alpha Alpha Alpha Alpha Alpha Alpha Alpha Alpha Alpha Alpha Lean Alpha Lean Alpha/Beta Lean Alpha/Beta Lean Lean Alpha/Beta Lean Alpha/Beta Alpha/Beta Lean Alpha/Beta Lean Lean Alpha/Beta Lean Alpha/Beta Alpha/Beta Lean Alpha/Beta Lean Lean Alpha/Beta Lean Alpha/Beta Alpha/Beta Lean Alpha/Beta Lean Alpha/Beta Alpha/Beta Alpha/Beta Alpha/Beta Alpha/Beta Alpha/Beta Alpha/Beta Alpha/Beta Alpha/Beta Alpha/Beta CREVICE CREVICE THRESHOLD CREVICE THRESHOLD CREVICE THRESHOLD THRESHOLD 80-90C 80-90C 80-90C 80-90C 80-90C 80-90C 80-90C >250C 80-90C >250C >250C >250C 80-90C 80-90C 80-90C ~150C 80-90C ~150C ~150C 80-90C ~150C 80-90C 80-90C 80C 80-90C 80C 80C 80C 80C 80C 80C 80C 80C 80C 80C 80C MECH MECH STR MECH STR MECH STR STR Low Low Low Low Low Low Low Low Low Low Low Low Medium Medium Medium Medium Medium Medium Medium Medium Medium Medium Medium High Medium High High High High High High High High High High High FEATURES FEATURES FEATURES Most formable grade-for FEATURES Most formable cladding & PHEgrade-for Most formable cladding & PHEgrade-for Most widely used titanium Most formable grade-for cladding & PHE Most widely used grade-best comb. titanium of props cladding & PHE Most widely used titanium grade-best comb. of props Added corrosion Most widely usedresistance titanium grade-best comb. of props Added corrosion over grade 2comb.resistance grade-best of props Added corrosion resistance over grade 2 Added corrosion resistance over grade 2 over grade 2 Added strength vs grade 2 Added strength vs grade 2 Added Added corrosion strength vsresistance grade 2 Added corrosion & strength vs grade 2 Added strength vsresistance grade 2 Added corrosion resistance & strength vs grade 2 Cold formable, med. Added corrosion resistance & strength vs grade 2 Cold formable, med. strength titanium alloy & strength vs grade 2 Cold formable, med. strength titanium alloy High Cold toughness/weldable formable, med. strength titanium alloy High toughness/weldable alloy for plate/fasteners strength titanium alloy High alloy toughness/weldable for plate/fasteners Std. alloy-some SCC High aero toughness/weldable alloy for plate/fasteners Std. aero alloy-some concerns in sea waterSCC alloy for plate/fasteners Std. aero alloy-some concerns in sea waterSCC Low oxygen grade 5-no Std. aero alloy-some SCC concerns in sea water Low oxygen grade 5-no SCC but lower concerns in seastrength water Low grade 5-no SCCoxygen but lower strength Low oxygen grade 5-no SCC but lower strength SCC but lower strength Titanium alloys Mechanical Properties 160 Tensile Yield Elongation 140 120 1240 High 1100 965 Medium 825 100 690 Low 80 550 60 415 40 275 20 138 0 0 1 2 3 12 9 32 ASTM Titanium Grade 23 5 Typical Strength (MPa) Typical Properties (ksi or %) 180 Titanium alloys Low Strength Grades (1, 2, 7, 11, 16, 17) • Grade 2 most readily available • Strength similar to austenitic SS • Pd/Ru does not affect mechanical props Medium Strength Grades (3, 12, 9, 28) • Can be cold formed (strip producible) • Available in all product forms • Strength similar to duplex SS • Highest strength ASME grades High Strength Grades (23, 29, 32, 5) • Common product forms are bar/billet/plate • Must use heat when forming • Weldability is best in grade 32 • Oxygen/Al content affect toughness and SCC Titanium alloys-Reducing acids 50 Corrosion Rate (mpy) 40 (1mm/yr) Grades 1-3 Ti Grade 9 Ti Grade 5, 23, 32 Ti 30 Grade 12 Ti 20 (.5mm/yr) Grade 16, 17 Ti 10 5mpy (.127mm/yr) Grade 7, 11 Ti 0 0 pH 1 1 2 3 pH 0 Boiling HCl Concentration (w t.%) 4 5 6 Localized Corrosion 14 - General Guidelines for Crevice Corrosion Resistance of Titanium in NaCl Brine Media pH Grades 1, 2, & 3 7- Crevice corrosion possible Grade 12 Pd Grades 7 & 16 00 150 Temperature (ºC) • Not susceptible to pitting or SCC attack (unalloyed grades) • All Ti grades resistant to crevice attack to about 80°C • Other grades (especially Pd) can be used up to >250°C 300 Corrosion - Galvanic Effects • Ti very noble in chlorides - almost always the cathode • Since Ti is cathode, no concern for corrosion • In galvanic couple, other metal may have accelerated corrosion attack • Hydrogen damage to Ti may occur if cathodic potential not regulated and if temperature > 80ºC CPI companies use Ti •Dow,Dupont •Shell, Chevron, BP (AMOCO) •Morton Salt •Kerr-McGee •Bayer •Heinz •BASF Ti application in CPI Reactor Vessel Ti lined reactor vessel for mining operation Ti application in CPI cont.. Tube Exchanger Straight heat tube exchanger Ti application in CPI cont.. Tube Exchanger Plate coil immersion heat exchanger Plate heat exchanger Ti application in CPI cont.. Ti tubed salt evaporator for table salt Ti application in CPI cont.. Ti anode baskets for anodized metal parts Benefits-Corrosion Resistance (Sea Water) Corrosion Mode Cu Alloys Al Alloys 316 SS Adv. SS Ni Alloys Titanium General Corrosion R/S R R R R R Erosion Corrosion S R R R R R Pitting Attack S S S R R R Crevice Corrosion S S S S S R Stress Corrosion R/S S R/S R R R MIC S S S S R R Weld Attack S S S S R R Galvanic Attack S S S R R R Composite Comp. S S S S S R S=Susceptible R=Resistance Benefits-Corrosion Resistance (Performance) Maximum Performance Minimum Performance Titanium ASTM Grades 7 & 16 Titanium ASTM Grade 12 Titanium ASTM Grade 2 / Alloy C-276, C22, 59 Alloy 625 6 Mo Stainless Steel / 2507 Stainless Steel 2205 Stainless Steel 316L Stainless Steel 304 Stainless Steel Galvanic series-Sea water Ti application Sea water application Centrifugal pumps Ti application Sea water application Cast pump for handling sea water Benefits-Density •Roughly half as dense as iron & nickel based alloys •A pound of titanium goes a lot further Titanium Zirconium Stainless Steel Nickel Copper Benefits Good Thermal Conductivity (12.5 Btu/Hr-Ft2-°F/ft) •30% above 300 series Stainless steel, •60% above the super stainless grades Low Elastic Modulus (15 Mpsi) •Titanium flexibility considered into design and fabrication (supports,shafts) Life cycle •Ti wins life cycle costing and proper design engineering (thin wall, no corrosion allowance) Benefits-Design Allowance ASME Design Allow./Unit Density (ksi/lb/cu in) 160 140 Grades 2,7&16Ti 120 Grade 3Ti 100 Grade 12Ti Grade 9Ti (Gr18) 80 316L SS 60 Alloy 625 40 C-276 20 0 0 100 200 300 400 Temperature (°F) 500 600 700 Cost considerations Total system installed cost & maintenance •Eliminate multiple installation/replacement costs •Reduced maintenance costs (oxide forms “slick” surface) •Titanium does not require coatings •Environmental/contamination costs (Ti non-toxic) •Reuse/recycle of Titanium Ti role in the CPI Mature Applications >30 yrs service history Industry Typical Areas Titanium Equipment Date of First Use Organic acid production Chlor-Alkali Salt production Chlorinated Hydrocarbons Heat exchangers, reactors, columns, piping, anodes Early 1960's Crude Overheads Desulfurizing Process cooling water Heat exchangers, piping Late 1960's Plating Electrowinning Hydrometallurgical Anodizing Anodes, cathodes, baskets, drums, heaters, exchangers, agitators, piping Late 1950's to early 1960's Waste Treatment WAO Heat exchangers, autoclaves Early 1970's Pulp/paper Mills Bleach plant Mixers, diffusion washers Mid to late 1950's Chemical Plants Refineries Metal Finishing Ti role in the CPI Newer Applications <20 yrs service history Industry Typical Areas Titanium Equipment Use Date Chemical/Refinery Mature + new processes/conditions Piping, tubing, advanced grade selection Ongoing Metals' Production Nickel Laterites Cu Anodes Clad vessels, piping, tubing, anodes, misc. equip. 90's Late 80's Geothermal Service water Nuclear waste-Yucca Mt. CP & Alloy piping, vessels, formed plate Mid 90's Late 80's ???? Oil & Gas Production Piping Fire water piping Alloy + CP piping, alloy sheet/billet Water Treatment SCWO RO Units Piping, Heat exchangers Power Generation 90's ??? 90's SUMMARY • Excellent chloride corrosion resistance • Wide selection of alloy properties without sacrificing corrosion resistance • Proven resistance to many organic chemicals • Environmentally friendly metal • Cost effective for CPI equipment • >40 years proven service in the CPI