Chassis Systems A5 Tasks Part 2

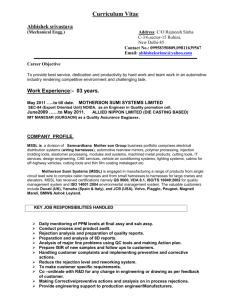

advertisement

1 Red Brake Warning Lamp Diagnosis Meets NATEF Task: (A5-B-11) Inspect, test and/or replace components of brake warning light system. (P-3) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Does the vehicle use a brake fluid level sensor? ___ Yes ___ No (If yes, describe the location: __________________________________.) _____ 2. Does the vehicle use a pressure differential switch? ___ Yes ___ No (If yes, describe the location: _________________________________________.) _____ 3. With the ignition key on, engine off (KOEO), apply the parking brake. Did the red brake warning lamp light? ___ Yes ___ No (If no, why not? ___________________________________________________) _____ 4. Unplug the wiring connector from the brake fluid level sensor or pressure differential switch. With the key on, engine off (KOEO), did the red brake warning lamp light? ___ Yes ___ No (It should not have come on.) _____ 5. State the vehicle manufacturer’s recommended inspection, testing, and replacement procedures: __________________________________________________________________ __________________________________________________________________ __________________________________________________________________ __________________________________________________________________ 2 Brake Stop Light Switch Meets NATEF Task: (A5-F-5) Check operation of brake stop light system and determine necessary action. (P-1) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Check the service information for the specified testing procedures to determine the proper operation and adjustment of the brake stop light switch. ________________ _______________________________________________________________ _______________________________________________________________ _____ 2. Check for the proper operation of the brake (stop) lights including the center highmounted stop light (CHMSL). OK ____ NOT OK ____ If not OK, determine the necessary action needed to restore proper operation. _______________________________________________________________ _______________________________________________________________ _____ 3. Describe the location of the brake switch _________________________________ _____ 4. Describe how to adjust the brake switch (if adjustable) ______________________ _______________________________________________________________ _____ 5. List the trade number of the brake light bulbs, including the center high-mounted stop light. Rear brake light trade number = _______________ Center high-mounted stop light trade number = ______________ _____ 6. Based on the test results, what is the necessary action? _________________________ _________________________________________________________________ _________________________________________________________________ 3 Brake Hoses and Lines Meets NATEF Task: (A5-B-6, A5-B-7, and A5-B-8) Brake hose and line inspection and replacement. (P-1) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Check service information for the specified procedure to follow when inspecting and/or replacing brake hoses and lines. Describe the recommended procedures. __________________________________________________________________ __________________________________________________________________ _____ 2. Based on the inspection of the brake lines and hoses, what is the necessary action? ________________________________________ ________________________________________ ________________________________________ ________________________________________ _____ 3. Using the specified diameter of brake line, perform the two brake line flaring procedure. _____ Double flare Instructor’s check ___________ _____ ISO (bubble) flare Instructor’s check ___________ _____ 4. Bend brake line as needed. Instructor’s check ___________ 4 Brake Fluid Meets NATEF Task: (A5-B-9 and A5-B-13) Brake fluid usage and test for contamination. (P-1) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Check service information for the specified brake fluid and when to check for the proper level. A. Specified brake fluid = ____________________________________________ B. Specified brake fluid level _________ (describe the location) _____________ _____ 2. Check service information for the recommended procedure to follow to determine if the brake fluid is contaminated. Describe the specified procedure: __________________________________________________________________ __________________________________________________________________ _____ 3. Check all that apply according to service information. ____ Perform a visual inspection. ____ Place the sample in styrofoam cup and check for eating away of the cup at the top of the fluid level line. ____ Use a test strip. ____ Use a brake fluid boiling temperature tester ____ Other (describe) ___________________________________________ 5 Brake Bleeding Meets NATEF Task: (A5-B-12) Bleed and/or flush the brake system. (P-1) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Check service information for the specified procedure to follow when bleeding and/or flushing the brake system. Describe the specified procedure. _________________________________________________________________ _________________________________________________________________ _____ 2. Perform a brake bleeding/flushing procedure. Instructor’s check _____________ _____ 3. Which method(s) was used (check all that apply)? ____ Normal (single stroke) method ____ Pressure bleeding ____ Vacuum bleeding ____ Gravity bleeding ____ Brake system was flushed _____ 4. Was the use of a scan tool needed or suggested? ____ Yes (What scan tool?) ________________________________________ ____ No 6 Wheel Bearing Diagnosis Meets NATEF Task: (A5-F-1) Determine wheel bearing noises, wheel shimmy, and vibration concerns; determine necessary action. (P-1) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK Worn or defective wheel bearings can cause a variety of concerns including: Noise – usually a growl or rumble that changes tone with vehicle speed. Wheel Shimmy – Can occur if the bearings are loose or excessively worn. Vibration – Can occur if the bearings are loose or excessively worn. _____ 1. Check service information for the recommended test procedures to follow to diagnose possible wheel bearing noise. ______________________________ ______________________________ _____ 2. Drive the vehicle and check for abnormal noise that could be caused by a defective wheel bearing. OK _____ NOT OK _____ HINT: A defective wheel bearing often sounds like a noisy winter tire but does not change tone when the vehicle is being driven over various road surfaces. _____ 3. Hoist the vehicle safely and check for excessive wheel bearing play and/or noise. OK _____ NOT OK _____ Describe the faults and location: _______________________________________ _____ 4. Based on the diagnosis, what is the necessary action? _________________________ _________________________________________________________________ 7 Wheel Bearing Service Meets NATEF Task: (A5-F-2) Remove, clean, inspect, repack, and install wheel bearings and replace seals; install hub and adjust bearings. (P-1) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Remove the wheel cover and the hub dust cap (grease cap). _____ 2. Remove and discard the cotter key. _____ 3. Remove the spindle nut, washer and outer bearing. _____ 4. Remove inner and outer bearing and grease seal. _____ 5. Thoroughly clean the bearing in solvent and denatured alcohol or brake cleaner and blow it dry with compressed air. _____ 6. Closely inspect the bearing for wear or damage. _____ 7. Show the instructor the cleaned bearing. Instructor's OK _______________ _____ 8. Repack the bearing with the correct type of wheel bearing grease. _____ 9. Install a new grease seal using a seal installing tool. _____ 10. Correctly adjust the bearing preload: ____ Install the spindle nut and while rotating the tire assembly, tighten (snug only, 12 to 30 lb.-ft.) with a wrench to "seat" the bearing correctly in the race. _____ While still rotating the tire assembly, loosen the nut approximately 1/2 turn and then hand tighten only. _____ Install a new cotter key (the common size is 1/8” diameter and 1.5 inches long). _____ Bend the ends of the cotter key up and around the nut to prevent interference with the dust cap. _____ 11. Install the hub dust cap (grease cap) and wheel cover. 8 Wheel Bearing and Race Replacement Meets NATEF Task: (A5-F-6) Replace wheel bearing and race. (P-2) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Remove the wheel cover and the hub dust cap (grease cap). _____ 2. Remove and discard the cotter key. _____ 3. Remove the spindle nut, washer and outer bearing. _____ 4. Remove inner and outer bearing and grease seal. _____ 5. Remove the bearing race using the specified tool. _____ 6. Show the instructor the removed race. Instructor's OK _______________ _____ 7. Install new race using the correct bearing race installation tool. _____ 8. Show the instructor the new race. Instructor's OK _______________ _____ 9. Install a new grease seal using a seal installing tool. _____ 10. Pack the new bearing with the correct type of wheel bearing grease. _____ 11. Correctly adjust the bearing preload: ____ Install the spindle nut and while rotating the tire assembly, tighten (snug only, 12 to 30 lb.-ft.) with a wrench to "seat" the bearing correctly in the race. _____ While still rotating the tire assembly, loosen the nut approximately 1/2 turn and then hand tighten only. _____ Install a new cotter key (the common size is 1/8” diameter and 1.5 inches long). _____ Bend the ends of the cotter key up and around the nut to prevent interference with the dust cap. _____ 12. Install the hub dust cap (grease cap) and wheel cover. 9 Inspect and Replace Wheel Studs Meets NATEF Task: (A5-F-7) Inspect and replace wheel studs. (P-1) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Hoist the vehicle safely. _____ 2. Remove all four wheels. _____ 3. Carefully inspect the wheel studs for excessive rust or damage. LF = OK _____ NOT OK _____ Describe fault ______________________ RF = OK _____ NOT OK _____ Describe fault ______________________ LR = OK _____ NOT OK _____ Describe fault ______________________ RR = OK _____ NOT OK _____ Describe fault ______________________ _____ 4. Clean the threads using a stiff wire brush. CAUTION: Many vehicle manufacturers specify that grease or oil should not be used on the threads of wheel studs. If a lubricant is used on the threads, the lug nuts could loosen during vehicle operation, which could cause a wheel to fall off resulting in a collision and possible personal injury. _____ 5. Worn or damaged studs should be replaced. Check the service information for the specified procedure for replacing wheel studs on the vehicle being serviced. __________________________________________________________________ _____ 6. Which stud(s) were replaced? _____________________________________ 10 Sealed Wheel Bearing Replacement Meets NATEF Task: (A5-F-8) Remove and reinstall sealed wheel bearing assembly. (P-1) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Check service information for the specified replacement procedure for the vehicle being serviced. _______________________________________________________ ________________________________________________________________ _____ 2. Loosen (do not remove) the drive axle shaft nut. _____ 3. Hoist the vehicle safely to a good working height (about chest high). _____ 4. Remove the front wheel. _____ 5. Use a steel drift between the caliper and the rotor cooling vent hole to hold the rotor from rotating. _____ 6. Remove the drive axle shaft hub nut. _____ 7. Remove the front disc brake caliper. _____ 8. Remove the rotor, the hub, and splash shield retaining bolts. _____ 9. Mark the location of the hub and make certain the hub is loose on the steering knuckle. _____ 10. Install the hub puller and remove the bearing and hub assembly. _____ 11. Clean and lubricate hub bearing surface. _____ 12. Reinstall the hub and bearing using the drive axle shaft nut. (Do not torque to the final setting, just until the hub is seated.) _____ 13. Reinstall the rotor, caliper, and wheel. _____ 14. Lower the vehicle and tighten the drive axle shaft nut to the final specification. Specification = _______________ (usually about 200 lb.-ft.) 11 Drum Brake Identification Meets NATEF Task: (None Specified) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Check service information and determine the following information regarding the drum brake design and features for the vehicle (check all that apply): ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ Dual servo Leading trailing Clip-on wheel cylinder Bolted on wheel cylinder Cast iron brake drum Aluminum brake drum Single U-spring design Clip-type holddown Coil-spring holddown Cable-operated self adjust Other (describe) _________ _____________________ _____________________ _____ 2. What is the brake drum diameter? ___________________________ _____ 3. What is the minimum allowable lining thickness? ________________________________ _____ 4. What is the maximum allowable brake drum diameter? _________________________________ 12 Drum Brake Problem Diagnosis Meets NATEF Task: (A5-C-1) Diagnose poor stopping, noise, vibration, pulling, grabbing, dragging, or pedal pulsation concerns; determine necessary action. (P-1) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Verify drum brake problem concerns. _____ Noise (describe) ____________________________________________ _____ Poor stopping _____ Pulling (toward which side?) ________________________ _____ Grabbing (when?) ___________________________________________ _____ Dragging _____ Brake pedal pulsation _____ 2. Hoist the vehicle safely. _____ 3. Wet the brake drum or install a vacuum enclosure to provide protection against possible asbestos dust. _____ 4. Remove the brake drums. _____ 5. Describe the condition of the drum brake parts: _____ Brake drum _________________________________________________ _____ Lining _____________________________________________________ _____ Springs ____________________________________________________ _____ Self-adjuster ________________________________________________ _____ Backing plate _______________________________________________ _____ 6. Based on the diagnosis, what is the necessary action? _________________________________________________________________ _________________________________________________________________