Operations - Providence University College

advertisement

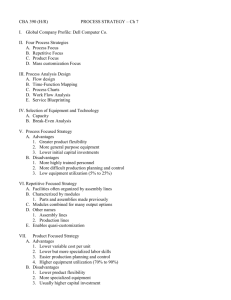

Operations 13-14 473.31 Fall 2015 Bruce Duggan Providence University College Summary Managing your supply chain effectively is a prerequisite for business success today. Supply chain design should include sourcing, inventory management, logistics, level of vertical integration, performance measurement, product design, and the design of the reverse supply chain. Outsourcing is an important way to reduce cost, while improving the strategic focus of the firm. Learning Objectives Review 1. What are some important sourcing considerations beyond simple material purchasing? 2. What are some of the contributing factors that cause the bullwhip effect in supply chains? 3. How can supply and demand characteristics influence how supply chains should be structured? 4. What are some reasons that can justify outsourcing? 5. What is meant by "green sourcing" and what should be included in a total cost of ownership analysis? 6. What are some metrics to measure supply chain performance? 7. What are the basic building blocks required for an effective mass customization program? 8. What are the five steps involved in collaborative planning, forecasting, and replenishment (CPFR)? 9. What is a reverse supply chain? Supply Chain Management Supply chain management involves optimizing the entire supply chain operations for the product by taking a systems approach to managing the flow of information, materials, and services from raw materials suppliers through factories and warehouses to the end costumer. Supply Chain Management 12-4 Strategic Sourcing Strategic Sourcing is the development and management of supplier relationships to acquire goods and services in a way that aids in achieving the immediate needs of the business. Strategic Sourcing Bullwhip Effect Bullwhip effect refers to the variability in demand is magnified as we move from the customer to the product in the supply chain. 12-7 Bullwhip Effect 12-8 Functional and Innovative Products Functional products • staples that people buy in a wide range of retail outlets, such as grocery stores and gas stations Innovative products • products such as fashionable clothes and personal computers that typically have a life cycle of just a few months Functional and Innovative Products Hau Lee’s Concepts of Supply Management 12-11 Hau Lee’s Concepts of Supply Management Hau Lee’s approach to supply chain (SC) is one of aligning SCs with the uncertainties revolving around the supply process side of the SC A stable supply process has mature technologies and an evolving supply process has rapidly changing technologies Types of SC’s • • • • Efficient SC’s Risk-Hedging SC’s Responsive SC’s Agile SC’s Logistics • the management functions that support the complete cycle of material flow: o from the purchase and internal control of production materials… o to the planning and control of work-in-process…. o to the purchasing, shipping, and distribution of the finished product Vertical Integration and Outsourcing Vertical Integration • the proportion of the supply chain that the company owns Outsourcing • the act of moving a firm’s internal activities and decision responsibility to outside providers Reasons for Outsourcing Greensourcing benefits: • Many firms are looking to their supply chains to deliver "green" results. • A significant area of focus relates to how a firm works with suppliers where the opportunity to save money and benefit the environment might not be a strict trade-off proposition. • Financial results can often be improved through both cost reductions and boosting revenues. Greensourcing Total Cost of Ownership (TCO) components: • • • • • • • • • Transportation Installation Inventory management Administration Order processing Training employees Data acquisition and evaluation Operating and maintenance Disposal. LO5 Total Cost of Ownership (TCO) Copyright © 2013 McGraw-Hill Ryerson Limited 12-16 Measuring Supply Chain Performance Inventory Turnover Calculation Mass Customization Mass customization the ability of a company to deliver highly customized products and services to different customers around the world. Process Postponement The key to mass customization is effectively postponing the tasks of differentiating a product for a specific customer until the latest possible point in the supply-chain network LO7 Mass Customization Principle 1: A product should be designed so it consists of independent modules that can be assembled into different forms of the product easily and inexpensively. Copyright © 2013 McGraw-Hill Ryerson Limited 12-24 LO7 Mass Customization Principle 2: Manufacturing and service processes should be designed so that they consist of independent modules that can be moved or rearranged easily to support different distribution network designs. Copyright © 2013 McGraw-Hill Ryerson Limited 12-25 LO7 Mass Customization Principle 3: The supply network should be designed to provide two capabilities. • First, the supply network should supply the basic product to the facilities performing the customization in an cost-effective manner. • Second, the supply network must have the flexibility and the responsiveness to take individual customers’ orders and deliver the finished, customized good quickly. Copyright © 2013 McGraw-Hill Ryerson Limited 12-26 Collaborative Planning, Forecasting, and Replenishment (CPFR) Collaborative Planning, Forecasting, and Replenishment (CPFR) • a technique used to coordinate demand forecasting, production and purchase planning, and inventory replenishment between supply chain trading partners. Collaborative Planning, Forecasting, and Replenishment (CPFR) Step 1. Creation of a front-end partnership agreement. Step 2. Joint business planning. Step 3. Development of demand forecasts. Step 4. Sharing forecasts. Step 5. Inventory replenishment. LO8 Collaborative Planning, Forecasting, and Replenishment (CPFR) Copyright © 2013 McGraw-Hill Ryerson Limited 12-29 Reverse Supply Chain Reverse Supply Chain • a series of activities required to retrieve a used product or return from a customer and either dispose of it or reuse it Reverse Supply Chain Five Components: • Product acquisition • Reverse logistics • Inspection and disposition • Reconditioning • Distribution and sales Reverse Supply Chain 12-32 The Successful Supply Chain Supply chains should be customized. Partnerships are important. Information should be shared. Holistic internal supply chain management. End of Chapter 13 Assigned problems for ch 13 Probs 1 & 4 • Hin Probs 2 & 3 • Ken Final Exam (take-home) company pages topic assigned to Hin Eastern Gear Ltd. 450-453 3 Operations strategy & process design US Stroller 453-458 5 Pull system vs manufacturing cells 3M 467-475 8 Quality (6 Sigma) Merriwell Beg 504-505 2 Forecasting Consolidated Electric 516-517 2 Inventory control Southern Toro 520-526 6 Inventory management Ken Toys Plus 527-530 3 Master production schedule Hin Ken