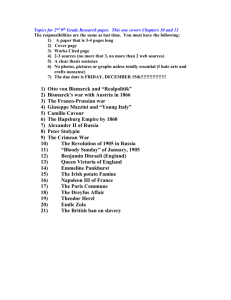

Location Lecture Material

advertisement

Facility Location COB 300C – Fall 2002 Facility Location Facility Location is the placement of facility with respect to customers, suppliers and other interacting facilities. It should consider: – – – – Operating costs Customer convenience Transportation costs Access to key related services such as banking and educational opportunities – Strategic factors Location as a Strategic Decision 1. Long-term commitment 2. Linked to customer base 3. Regional facility supplies specific area 4. Product facility supplies globally 5. Combination of regional and product facilities Regional or Global Factors Affecting the Location Decision Strategic nature of decision Quantitative factors Government incentives Qualitative factors Including the Qualitative Factors Integrate qualitative factors – Determine which factors are relevant to the problem – Weigh each factor – Rate each site for each factor Examples of Indianapolis and Lexington (Slide 1 of 2) Recreational activities University research facilities Union activities Banking services Available labor pool Weight Indianapolis Raw Score Lexington Raw Score 20 8 7 40 40 80 60 8 4 7 7 8 7 6 5 Examples of Indianapolis and Lexington (Slide 2 of 2) Indianapolis Weighted score Recreational activities University research facilities Union activities Banking services Available labor pool Total Lexington Weighted score 160 140 320 160 560 420 320 280 480 300 1,620 1,520 Analyzing Spatial Relationships Load-Distance Method measures proximity to customers, suppliers, interacting facilities Transportation Problem relates to the cost of transporting materials to and from multiple facilities Distance from Facility to Customer Health Care Unit Location Problem Locating a Health Care Center Using the “Load-Distance Method” (Slide 1 of 3) Population coordinates Zip Code ai 10111 10112 10113 10114 10115 10116 10117 30,000 25,000 11,000 8,000 18,000 24,000 12,000 Total 128,000 xi yi 3 2 1.5 3 3.5 4.5 5.25 2 4 5.5 7 5 3.5 6.25 (ai )(xi) (ai)(yi) 90,000 50,000 16,500 24,000 63,000 108,000 63,000 60,000 100,000 60,500 56,000 90,000 84,000 75,000 414,500 525,500 Locating a Health Care Center Using the “Load-Distance Method” (Slide 2 of 3) n n xf a x i i 1 i n (a ) i 1 i yf a y i i 1 i n (a ) i 1 i where xf = Distance along the x axis from the origin to the center of gravity yf = Distance along the y axis from the origin to the center of gravity ai = The activity level (load) from the i th location to the proposed facility Xi = the coordinate on the x axis for the i th customer location yi = the coordinate on the y axis for the i th customer location Locating a Health Care Center Using the “Load-Distance Method” (Slide 3 of 3) The coordinates of the center of gravity are: xf = 414,500 128,000 = 3.24 yf = 525,500 128,000 = 4.11 Transportation Problem Cost of moving materials between multiple destinations Vogel’s Approximation Method To evaluate two locations, solve the transportation problem for each location OR Transportation Example New facility capacity = 5000 units/month We must choose either Des Moines, Iowa or Montgomery, Alabama Transportation costs per unit for Des Moines and Montgomery to each customer location are provided We are interested in total transportation cost for Des Moines versus Montgomery Transportation Example (cont’d) Supply Lexington - 12,420 Milan - 9,380 DesMoines - 5,000 (proposed) or Montgomery - 5,000 (proposed) Transportation Example (cont’d) Demand Baton Rouge - 6,740 Bismarck - 8,400 Tampa - 5,050 Youngstown - 5,670 DESTINATION Baton Rouge Bismarck Tampa Youngstown Dummy CAPACITY SOURCE 14 18 16 12 0 12420 17 15 17 9 0 9380 17 11 19 14 0 5000 Lexington Milan DesMoines 6740 DEMAND 8400 5050 5670 940 26800 DESTINATION Baton Rouge Bismarck Tampa Youngstown Dummy CAPACITY SOURCE 14 18 16 12 0 12420 12 17 15 17 9 0 9380 9 17 11 19 14 0 5000 11 Lexington Milan DesMoines 6740 8400 5050 5670 940 26800 DEMAND 3 4 1 3 0 DESTINATION Baton Rouge Bismarck Tampa Youngstown Dummy CAPACITY SOURCE 14 18 16 12 0 12420 12 940 Lexington 17 15 17 9 0 9380 9 17 11 19 14 0 5000 11 Milan DesMoines 6740 8400 5050 5670 940 26800 DEMAND 3 4 1 3 0 DESTINATION Baton Rouge Bismarck Tampa Youngstown Dummy CAPACITY SOURCE 14 18 16 12 0 17 15 17 9 0 12420 11480 9380 17 11 19 14 0 5000 940 Lexington 2 3 6 Milan DesMoines 6740 8400 5050 5670 940 0 DEMAND 3 4 1 3 26800 DESTINATION Baton Rouge Bismarck Tampa Youngstown Dummy CAPACITY SOURCE 14 18 16 12 0 9 0 12420 11480 9380 14 0 5000 940 Lexington 17 15 17 2 3 6 5670 Milan 17 11 19 DesMoines 6740 8400 5050 5670 940 0 DEMAND 3 4 1 3 26800 DESTINATION Baton Rouge Bismarck Tampa Youngstown Dummy CAPACITY SOURCE 14 18 16 12 0 940 Lexington 17 15 17 9 0 14 0 5670 Milan 17 11 19 12420 11480 9380 3710 5000 DesMoines 6740 8400 5050 5670 0 DEMAND 3 4 1 940 0 26800 2 2 6 DESTINATION Baton Rouge Bismarck Tampa Youngstown Dummy CAPACITY SOURCE 14 18 16 12 0 940 Lexington 17 15 17 9 0 14 0 5670 Milan 17 11 5000 8400 DesMoines 6740 19 5050 5670 0 DEMAND 3 4 1 940 0 12420 11480 9380 3710 5000 26800 2 2 6 DESTINATION Baton Rouge Bismarck Tampa Youngstown Dummy CAPACITY SOURCE 14 18 16 12 0 940 Lexington 17 15 17 9 0 14 0 5670 Milan 17 11 5000 8400 3400 DesMoines 6740 DEMAND 3 19 5050 3 5670 0 1 940 0 12420 11480 9380 3710 5000 0 26800 2 2 DESTINATION Baton Rouge Bismarck Tampa Youngstown Dummy CAPACITY SOURCE 14 Lexington 18 16 12 6740 0 940 17 15 17 9 0 14 0 5670 Milan 17 11 5000 8400 3400 DesMoines 6740 DEMAND 3 19 5050 3 5670 0 1 940 0 12420 11480 9380 3710 5000 0 26800 2 2 DESTINATION Baton Rouge Bismarck Tampa Youngstown Dummy CAPACITY SOURCE 14 Lexington 18 16 6740 0 940 17 15 17 9 0 14 0 5670 Milan 17 DesMoines DEMAND 12 6740 0 11 5000 8400 3400 19 5050 3 5670 0 1 940 0 12420 4740 9380 3710 5000 0 26800 2 2 DESTINATION Baton Rouge Bismarck Tampa Youngstown Dummy CAPACITY SOURCE 14 Lexington 18 12 6740 15 17 3400 Milan 17 DesMoines 6740 0 0 940 17 DEMAND 16 9 0 14 0 5670 11 5000 8400 3400 19 5050 3 5670 0 1 940 0 12420 4740 9380 3710 5000 0 26800 2 2 DESTINATION Baton Rouge Bismarck Tampa Youngstown Dummy CAPACITY SOURCE 14 Lexington 18 12 6740 15 17 3400 Milan 17 DesMoines 6740 0 0 940 17 DEMAND 16 0 14 0 5670 11 5000 8400 0 9 19 5050 5670 0 1 940 0 12420 4740 9380 310 5000 0 26800 DESTINATION Baton Rouge Bismarck Tampa Youngstown Dummy CAPACITY SOURCE 14 Lexington 18 6740 15 17 17 6740 0 9 0 14 0 5670 11 5000 8400 0 0 940 3400 Milan DesMoines 12 4740 17 DEMAND 16 19 5050 5670 0 1 940 0 12420 4740 9380 310 5000 0 26800 DESTINATION Baton Rouge Bismarck Tampa Youngstown Dummy CAPACITY SOURCE 14 Lexington 18 6740 15 17 17 6740 0 9 0 14 0 5670 11 5000 8400 0 0 940 3400 Milan DesMoines 12 4740 17 DEMAND 16 19 5050 310 5670 0 940 0 12420 0 9380 310 5000 0 26800 DESTINATION Baton Rouge Bismarck Tampa Youngstown Dummy CAPACITY SOURCE 14 Lexington 18 6740 15 3400 Milan 17 DEMAND 6740 0 12 4740 17 DesMoines 16 5000 8400 0 940 17 310 11 9 0 14 0 5670 19 5050 310 0 5670 0 940 0 12420 0 9380 310 5000 0 26800 DESTINATION Baton Rouge Bismarck Tampa Youngstown Dummy CAPACITY SOURCE 14 Lexington 18 6740 15 3400 Milan 17 DEMAND 6740 0 12 4740 17 DesMoines 16 5000 8400 0 940 17 310 11 9 0 14 0 5670 19 5050 0 0 5670 0 940 0 12420 0 9380 0 5000 0 26800 Total Transportation Cost for Des Moines 6740($14)+4740($16)+940($0)+3400($15)+ 310($17)+5670($9)+5000($11) = $332,500 For Next Class Figure Transportation Cost for Montgomery Which is best choice based on Vogel’s Approximation? Are there other factors to consider? Montgomery’s Transportation Costs: – – – – Montgomery to Baton Rouge: $9 per unit Montgomery to Bismarck: $19 per unit Montgomery to Tampa: $12 per unit Montgomery to Youngstown $15 per unit Location Example - Load Distance Location of a warehouse in Germany Method: Load-Distance Method (a.k.a.: center-of-gravity method) Customer locations (coordinates) and demands in units per year are given CITY Hamburg Cologne Stuttgart Munich Dresden Berlin Demand ai (units/yr.) 42,000 22,000 37,000 66,000 45,000 113,000 Xi Yi 3.25 1 2.5 4.25 5.75 5.5 7 4.5 2 1.25 4.5 6 CITY Hamburg Cologne Stuttgart Munich Dresden Berlin Demand ai (units/yr.) 42,000 22,000 37,000 66,000 45,000 113,000 Xi Yi (ai)(xi) (ai)(yi) 3.25 1 2.5 4.25 5.75 5.5 7 4.5 2 1.25 4.5 6 136,500 22,000 92,500 280,500 258,750 621,500 294,000 99,000 74,000 82,500 202,500 678,000 CITY Demand ai (units/yr.) Hamburg Cologne Stuttgart Munich Dresden Berlin 42,000 22,000 37,000 66,000 45,000 113,000 TOTAL 325,000 Xi Yi (ai)(xi) (ai)(yi) 3.25 1 2.5 4.25 5.75 5.5 7 4.5 2 1.25 4.5 6 136,500 22,000 92,500 280,500 258,750 621,500 294,000 99,000 74,000 82,500 202,500 678,000 1,411,750 1,430,000 n (a )(x ) i xf = i i=1 n a 1,411,750 4.34 325,000 i i=1 n (a )(y ) i yf = i i=1 n a i i=1 1,430,000 4.40 325,000 Show map here Location? Central Germany Other Factors to Consider? operating costs required investment government incentives qualitative factors overall strategy of organization Location Decision Affects Other Operating Decisions Alternative to on-site expansion On-site expansion is problematic – Material handling and storage – Complex production flow – Strained communication – New technology delayed – Use of old equipment – Layering of expanded responsibilities International Dimensions of Location Decision Reasons for locating in foreign countries – Comparative Advantage – Closeness to market – Political relationships – Availability of resources Location Analysis for Service Operations Concepts and techniques discussed so far apply to service operations Service issues: » Minimize response time: Emergency medical services » Provide minimum coverage: Fire Protection » Mobile location: Police or security units