Basic Business Statistics (9th Edition)

© 2004 Prentice-Hall, Inc.

Basic Business Statistics

(9 th Edition)

Chapter 18

Statistical Applications in Quality and Productivity Management

Chap 18-1

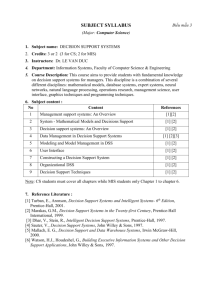

Chapter Topics

Total Quality Management (TQM)

Theory of Management (Deming’s Fourteen

Points)

Six Sigma ® Management Approach

The Theory of Control Charts

Common-cause variation versus special-cause variation

Control Charts for the Proportion of

Nonconforming Items

© 2004 Prentice-Hall, Inc. Chap 18-2

Chapter Topics

(continued)

Process Variability

The c Chart

Control Charts for the Mean and the Range

Process Capability

© 2004 Prentice-Hall, Inc. Chap 18-3

Themes of Quality Management

1. Primary Focus on Process Improvement

2. Most Variation in Process Due to System

3. Teamwork is Integral to Quality Management

4. Customer Satisfaction is a Primary Goal

5. Organizational Transformation Necessary

6. Remove Fear

7. Higher Quality Costs Less

Chap 18-4 © 2004 Prentice-Hall, Inc.

Deming’s 14 Points:

Point 1:

Point 1. Create Constancy of Purpose

Act

Plan

Study

Do

© 2004 Prentice-Hall, Inc.

The Shewhart-Deming Cycle

Focuses on Constant Improvement

Chap 18-5

Deming’s 14 Points:

Points 2 and 3

Point 2. Adopt New Philosophy

Better to be proactive and change before crisis occurs.

Point 3. Cease Dependence on Mass

Inspection to Achieve Quality

Any inspection whose purpose is to improve quality is too late.

© 2004 Prentice-Hall, Inc. Chap 18-6

Deming’s 14 Points:

Points 4 and 5

Point 4. End the Practice of Awarding Business on the

Basis of Price Tag Alone

Develop long term relationship between purchaser and supplier .

Point 5. Improve Constantly and Forever

Reinforce the importance of the

Shewhart-Deming cycle.

Chap 18-7 © 2004 Prentice-Hall, Inc.

Deming’s 14 Points:

Points 6 and 7

Point 6. Institute Training

Especially important for managers to understand the difference between special causes and common causes.

Point 7. Adopt and Institute Leadership

Differentiate between leadership and supervision.

Leadership is to improve the system and achieve greater consistency of performance.

Chap 18-8 © 2004 Prentice-Hall, Inc.

Deming’s 14 Points:

Points 8 to 12

8. Drive Out Fear

9. Break Down Barriers between Staff Areas

10. Eliminate Slogans

11. Eliminate Numerical Quotas for Workforce and Numerical Goals for Management

12. Remove Barriers to Pride of

Workmanship

300

Chap 18-9 © 2004 Prentice-Hall, Inc.

Deming’s 14 Points:

Points 13 and 14

Point 13. Encourage Education and Self-Improvement for Everyone

Quality is important

Improved knowledge of people will improve the assets of the organization.

Point 14. Take Action to Accomplish Transformation

© 2004 Prentice-Hall, Inc.

Continually strive toward improvement.

Chap 18-10

Six Sigma ® Management

A Managerial Approach Designed to Create

Processes that Result in No More Than 3.4

Defects Per Million

A Method for Breaking Processes into a Series of Steps in Order to Eliminate Defects and

Produce Near Perfect Results

(1) Define: Define the problem along with costs, benefits and the impact on customers

(2) Measure: Develop operational definitions for each Critical-to-Quality characteristic and verify measurement procedure to achieve consistency over repeated measurements

© 2004 Prentice-Hall, Inc. Chap 18-11

Six Sigma ® Management

(continued)

(3) Analyze: Use control charts to monitor defects and determine the root causes of defects

(4) Improve: Study the importance of each process variable on the Critical-to-Quality characteristic to determine and maintain the best level for each variable in the long term

(5) Control: Avoid potential problems that occur when a process is changed and maintain the gains that have been made in the long term

Chap 18-12 © 2004 Prentice-Hall, Inc.

Control Charts

Monitor Variation in Data

Exhibit trend - make correction before process is out of control

A Process - A Repeatable Series of Steps

Leading to a Specific Goal

© 2004 Prentice-Hall, Inc. Chap 18-13

Control Charts

(continued)

Show When Changes in Data are Due to:

Special or assignable causes

Fluctuations not inherent to a process

Represent problems to be corrected

Data outside control limits or trend

Chance or common causes

Inherent random variations

Consist of numerous small causes of random variability

Chap 18-14 © 2004 Prentice-Hall, Inc.

Process Control Chart

Graph of sample data plotted over time

Special

Cause

Variation

80

60

40

Common

20

0

X

Cause

1 2 3 4 5 6 7 8 9 101112

Time

Variation

UCL

LCL

Mean

Process

Average

© 2004 Prentice-Hall, Inc. Chap 18-15

Control Limits

UCL = Process Average + 3 Standard Deviations

LCL = Process Average - 3 Standard Deviations

X

UCL

+ 3

Process

Average

- 3

LCL

TIME

© 2004 Prentice-Hall, Inc. Chap 18-16

Types of Error

First Type:

Belief that observed value represents special cause when, in fact, it is due to common cause

Second Type:

Treating special cause variation as if it is common cause variation

© 2004 Prentice-Hall, Inc. Chap 18-17

X

Comparing Control Chart

Patterns

X X

Common Cause

Variation: No Points

Outside Control

Limits

Special Cause

Variation: 2 Points

Outside Control

Limits

© 2004 Prentice-Hall, Inc.

Downward Pattern:

No Points Outside

Control Limits but

Trend Exists

Chap 18-18

When to Take Corrective Action

Corrective Action Should Be Taken When

Observing Points Outside the Control Limits or when a Trend Has Been Detected

Eight consecutive points above the center line (or eight below)

Eight consecutive points that are increasing

(decreasing)

Chap 18-19 © 2004 Prentice-Hall, Inc.

Out-of-Control Processes

If the Control Chart Indicates an Out-of-

Control Condition (a Point Outside the Control

Limits or Exhibiting Trend)

Contains both common causes of variation and assignable causes of variation

The assignable causes of variation must be identified

If detrimental to quality, assignable causes of variation must be removed

If increases quality, assignable causes must be incorporated into the process design

© 2004 Prentice-Hall, Inc. Chap 18-20

In-Control Process

If the Control Chart is Not Indicating Any Outof-Control Condition, then

Only common causes of variation exist

It is sometimes said to be in a state of statistical control

If the common-cause variation is small, then control chart can be used to monitor the process

If the common-cause variation is too large, the process needs to be altered

Chap 18-21 © 2004 Prentice-Hall, Inc.

p Chart

Control Chart for Proportions

Is an attribute chart

Shows Proportion of Nonconforming Items

E.g., Count # of nonconforming chairs & divide by total chairs inspected

Chair is either conforming or nonconforming

Used with Equal or Unequal Sample Sizes Over

Time

Unequal sizes should not differ by more than ±25% from average sample size

Chap 18-22 © 2004 Prentice-Hall, Inc.

p Chart

Control Limits

LCL p

3 p (1

p ) n

UCL p

3 p (1

p ) n

Average Group Size n

i k

1 n i k

# of Samples

© 2004 Prentice-Hall, Inc. p

Average Proportion of

Nonconforming Items

i k

1

X i i k

1 n i

# Defective

Items in

Sample i

Size of

Sample i

Chap 18-23

You’re manager of a

500-room hotel. You want to achieve the highest level of service. For 7 days, you collect data on the readiness of 200 rooms. Is the process in control?

© 2004 Prentice-Hall, Inc. p Chart

Example

Chap 18-24

© 2004 Prentice-Hall, Inc. p Chart

Hotel Data

# Not

Day # Rooms Ready Proportion

5

6

7

3

4

1

2

200

200

200

200

200

200

200

16

7

21

17

25

19

16

0.080

0.035

0.105

0.085

0.125

0.095

0.080

Chap 18-25

n

i k

1 n i k

p

3 p

n

© 2004 Prentice-Hall, Inc. p Chart

Control Limits Solution

1400

7

200

16 + 7 +...+ 16 p

i k

1

X i i k

1 n i

121

1400

.0864

200

Chap 18-26

p Chart

Control Chart Solution

0.15

P

0.10

0.05

0.00

UCL

LCL

1 2 3 4 5 6 7

Day

Mean p p

Any improvement in the process must come from reduction of common-cause variation, which is the responsibility of the management.

© 2004 Prentice-Hall, Inc. Chap 18-27

p Chart in PHStat

PHStat | Control Charts | p Chart …

Excel Spreadsheet for the Hotel Room

Example

© 2004 Prentice-Hall, Inc. Chap 18-28

Understanding Process Variability:

Red Bead Example

Four workers (A, B, C, D) spend 3 days to collect beads, at 50 beads per day. The expected number of red beads to be collected per day per worker is 10 or 20%.

Worker

A

B

C

Day 1

9 (18%)

12 (24%)

13 (26%)

D 7 (14%)

Totals

© 2004 Prentice-Hall, Inc.

41

Day 2 Day 3 All Days

11 (12%) 6 (12%) 26 (17.33%)

12 (24%) 8 (16%) 32 (21.33%)

6 (12%) 12 (24%) 31(20.67%)

9 (18%) 8 (16%) 24 (16.0%)

38 34 113

Chap 18-29

Understanding Process Variability:

Example Calculations

Average Day 1

_

X 10.25

p 20.5%

Day 2

9.5

19% p

113

50(12)

.1883

p

3 p (1

p )

n

LCL

.1883 .1659

.0224

UCL

.1883 +.1659

.3542

© 2004 Prentice-Hall, Inc.

Day 3

8.5

17%

All Days

9.42

18.83%

50

Chap 18-30

Understanding Process Variability:

Example Control Chart

UCL

.30

.20

.10

0 A

1

B

1

C

1

D

1

A

2

B

2

C

2

D

2

A

3

B

3

LCL

C

3

D

3

_ p

Chap 18-31 © 2004 Prentice-Hall, Inc.

Morals of the Example

Variation is an inherent part of any process.

The system is primarily responsible for worker performance.

Only management can change the system.

Some workers will always be above average, and some will be below.

© 2004 Prentice-Hall, Inc. Chap 18-32

The c Chart

Control Chart for Number of Nonconformities

(Occurrences) in a Unit (an Area of

Opportunity)

Is an attribute chart

Shows Total Number of Nonconforming Items in a Unit

E.g., Count # of defective chairs manufactured per day

Assume that the Size of Each Subgroup Unit

Remains Constant

© 2004 Prentice-Hall, Inc. Chap 18-33

c Chart Control Limits

LCL c 3 c c

UCL c 3 c c

Average Number of c

i

1 c i k

# of Occurrences in Sample i

# of Samples

© 2004 Prentice-Hall, Inc. Chap 18-34

c Chart: Example

You’re manager of a

500-room hotel. You want to achieve the highest level of service. For 7 days, you collect data on the readiness of 200 rooms. Is the process in control?

© 2004 Prentice-Hall, Inc. Chap 18-35

© 2004 Prentice-Hall, Inc. c Chart: Hotel Data

# Not

Day # Rooms Ready

5

6

7

3

4

1

2

200

200

200

200

200

200

200

16

7

21

17

25

19

16

Chap 18-36

c Chart:

Control Limits Solution i k

1 c i c

16 7 19 16 k

LCL c

3 c

7

17.286

17.286 3 17.285

4.813

UCL c

3 c

29.759

Chap 18-37 © 2004 Prentice-Hall, Inc.

c Chart:

Control Chart Solution c

30 UCL

20 c

10

LCL

0

1 2 3 4 5 6 7

Day c

Any improvement in the process must come from reduction of common-cause variation, which is the responsibility of the management.

Chap 18-38 © 2004 Prentice-Hall, Inc.

Variables Control Charts:

R Chart

Monitors Variability in Process

Characteristic of interest is measured on numerical scale

Is a variables control chart

Shows Sample Range Over Time

Difference between smallest & largest values in inspection sample

E.g., Amount of time required for luggage to be delivered to hotel room

Chap 18-39 © 2004 Prentice-Hall, Inc.

R Chart

Control Limits

© 2004 Prentice-Hall, Inc.

UCL

R

D R

4

LCL

R

D R

3

R

i k

1 k

R i

From

Table

Sample Range at

Time i or Sample i

# Samples

Chap 18-40

You’re manager of a

500-room hotel. You want to analyze the time it takes to deliver luggage to the room. For 7 days, you collect data on 5 deliveries per day. Is the process in control?

© 2004 Prentice-Hall, Inc.

R Chart

Example

Chap 18-41

© 2004 Prentice-Hall, Inc.

R Chart and Mean Chart

Hotel Data

Sample Sample

Day Average Range

5

6

7

3

4

1

2

5.32

6.59

4.88

5.70

4.07

7.34

6.79

3.85

4.27

3.28

2.99

3.61

5.04

4.22

Chap 18-42

R Chart

Control Limits Solution

R

i k

1

R i k

3.85 4.27

4.22

7

3.894

UCL

R

D R

4

2.114 3.894

8.232

LCL

R

D R

3

0 3.894

0

From Table

( n = 5)

Chap 18-43 © 2004 Prentice-Hall, Inc.

R Chart

Control Chart Solution

© 2004 Prentice-Hall, Inc.

6

4

2

0

8

Minutes UCL

LCL

1 2 3 4 5 6 7

Day

_

R

Chap 18-44

Variables Control Charts: Mean

X

Shows Sample Means Over Time

Compute mean of inspection sample over time

E.g., Average luggage delivery time in hotel

Monitors Process Average

Must be preceded by examination of the R chart to make sure that the process is in control

© 2004 Prentice-Hall, Inc. Chap 18-45

Mean Chart

X

UCL

X

X

A R

2

LCL

X

X

A R

2

i k

1

X i k

and R

i k

1

Computed

From

Table

Sample

Mean at

Time i

Sample

Range at Time i k

R i

# Samples

Chap 18-46 © 2004 Prentice-Hall, Inc.

Mean Chart Example

You’re manager of a

500-room hotel. You want to analyze the time it takes to deliver luggage to the room.

For 7 days, you collect data on 5 deliveries per day. Is the process in control?

© 2004 Prentice-Hall, Inc. Chap 18-47

© 2004 Prentice-Hall, Inc.

R Chart and Mean Chart

Hotel Data

Sample Sample

Day Average Range

5

6

7

3

4

1

2

5.32

6.59

4.88

5.70

4.07

7.34

6.79

3.85

4.27

3.28

2.99

3.61

5.04

4.22

Chap 18-48

Mean Chart

Control Limits Solution

X

R

i k i k

1

X i

1 k k

R i

5.32

6.59

6.79

7

3.85

4.27

7

4.22

5.813

From

Table E.9

3.894

( n = 5)

UCL

X

X

A

2

5.813

8.060

LCL

X

X

A

2

5.813

3.566

Chap 18-49 © 2004 Prentice-Hall, Inc.

© 2004 Prentice-Hall, Inc.

Mean Chart

Control Chart Solution

4

2

0

8

Minutes

6

UCL

LCL

1 2 3 4 5 6 7

Day

X

Chap 18-50

R Chart and Mean Chart in PHStat

PHStat | Control Charts | R & Xbar Charts …

Excel Spreadsheet for the Hotel Room

Example

© 2004 Prentice-Hall, Inc. Chap 18-51

Process Capability

Process Capability is the Ability of a Process to

Consistently Meet Specified Customer-Driven

Requirements

Specification Limits are Set by Management in

Response to Customer’s Expectations

The Upper Specification Limit (USL) is the

Largest Value that Can Be Obtained and Still

Conform to Customer’s Expectation

The Lower Specification Limit (LSL) is the

Smallest Value that is Still Conforming

© 2004 Prentice-Hall, Inc. Chap 18-52

Estimating Process Capability

Must Have an In-Control Process First

Estimate the Percentage of Product or Service

Within Specification

Assume the Population of X Values is

Approximately Normally Distributed with Mean

Estimated by

2

Chap 18-53 © 2004 Prentice-Hall, Inc.

Estimating Process Capability

(continued)

For a Characteristic with an LSL and a USL

P(an outcome will be within specification)

P( LSL

X

USL )

= P

LSL

X

2

USL

2

X

where Z is a standardized normal random variable

Chap 18-54 © 2004 Prentice-Hall, Inc.

Estimating Process Capability

(continued)

For a Characteristic with Only a LSL

P(an outcome will be within specification)

P( LSL

X )

= P

LSL

X

2

Z

where Z is a standardized normal random variable

Chap 18-55 © 2004 Prentice-Hall, Inc.

Estimating Process Capability

(continued)

For a Characteristic with Only a USL

P(an outcome will be within specification)

P( X

USL )

= P

Z

USL

X

2

where Z is a standardized normal random variable

Chap 18-56 © 2004 Prentice-Hall, Inc.

Process Capability Example

You’re manager of a 500room hotel. You have instituted a policy that

99% of all luggage deliveries must be completed within 10 minutes or less. For 7 days, you collect data on 5 deliveries per day.

Is the process capable?

© 2004 Prentice-Hall, Inc. Chap 18-57

© 2004 Prentice-Hall, Inc.

Process Capability:

Hotel Data

Sample Sample

Day Average Range

5

6

7

3

4

1

2

5.32

6.59

4.88

5.70

4.07

7.34

6.79

3.85

4.27

3.28

2.99

3.61

5.04

4.22

Chap 18-58

Process Capability:

Hotel Example Solution n

5 X

5.813

R

3.894

and d

2

2.326

P(A delivery is made within specification)

= P( X

10)

= P Z

3.894 / 2.326

= P( Z

2.50)

.9938

© 2004 Prentice-Hall, Inc.

Therefore, we estimate that 99.38% of the luggage deliveries will be made within the 10 minutes or less specification. The process is capable of meeting the 99% goal.

Chap 18-59

Capability Indices

Aggregate Measures of a Process’ Ability to

Meet Specification Limits

The larger (>1) the values, the more capable a process is of meeting requirements

Measure of Process Potential Performance

C p

USL

LSL

6

/

2

specification spread process spread

C p

>1 implies that a process has the potential of having more than 99.73% of outcomes within specifications

Chap 18-60 © 2004 Prentice-Hall, Inc.

Capability Indices

(continued)

Measures of Actual Process Performance

For one-sided specification limits

CPL

X

LSL

3

/

2

CPU

USL

X

3

/

2

CPL (CPU)

>1 implies that the process mean is more than 3 standard deviations away from the lower (upper) specification limit

Chap 18-61 © 2004 Prentice-Hall, Inc.

Capability Indices

(continued)

For two-sided specification limits

C

min

CPL CPU

C pk pk

= 1 indicates that the process average is 3 standard deviations away from the closest specification limit

Larger

C pk indicates larger capability of meeting the requirements

© 2004 Prentice-Hall, Inc. Chap 18-62

Process Capability Example

You’re manager of a 500room hotel. You have instituted a policy that all luggage deliveries must be completed within 10 minutes or less. For 7 days, you collect data on 5 deliveries per day.

Compute an appropriate capability index for the delivery process.

© 2004 Prentice-Hall, Inc. Chap 18-63

© 2004 Prentice-Hall, Inc.

Process Capability:

Hotel Data

Sample Sample

Day Average Range

5

6

7

3

4

1

2

5.32

6.59

4.88

5.70

4.07

7.34

6.79

3.85

4.27

3.28

2.99

3.61

5.04

4.22

Chap 18-64

Process Capability:

Hotel Example Solution n

5 X

5.813

R

3.894

and d

2

2.326

CPU

USL

X

3

/

2

0.833672

Since there is only the upper specification limit, we need to only compute

CPU

. The capability index for the luggage delivery process is .8337, which is less than 1. The upper specification limit is less than 3 standard deviations above the mean.

© 2004 Prentice-Hall, Inc. Chap 18-65

Chapter Summary

Described Total Quality Management (TQM)

Addressed the Theory of Management

Deming’s 14 Points

Described the Six Sigma ® Management

Approach

Discussed the Theory of Control Charts

Common-cause variation versus special-cause variation

Chap 18-66 © 2004 Prentice-Hall, Inc.

Chapter Summary

(continued)

Computed Control Charts for the Proportion of

Nonconforming Items

Described Process Variability

Described c Chart

Computed Control Charts for the Mean and the Range

Discussed Process Capability

Chap 18-67 © 2004 Prentice-Hall, Inc.