Center For Scalable and Integrated NAnoManufacturing

advertisement

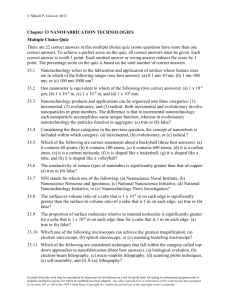

Center For Scalable and Integrated NAnoManufacturing NSF Nanoscale Science and Engineering Center (NSEC), Award # CMMI-0751621 UC Berkeley • UCLA • Stanford • Northwestern • UNCC • HP Labs 3116 Etcheverry Hall, University of California, Berkeley, CA 94720-1740, http://www.sinam.org Introduction IRG I. Top-Down NAnoManufacturing Vision: A New Nano Manufacturing Paradigm that Enables the Quantum Leap from Lab Science to Industry Revolution • Future Integrated Nano-Systems • • Critical Challenges Prohibitive cost (EUV>$25M/tool), low speed (EBL) Not suitable for 3D (nanoimprint, soft lithography) Prone to defects (self-assembly) • Goal Technological Barriers 3D Terabit Memory Ultra Sensitive Bio-sensor Self-assembly CANNOT: Heterogeneously assemble pattern for devices Avoid “defects” due to thermodynamic nature Ultra Molding Impring Lithography • Deposition Nano-manufacturing with 1-100 nm resolution SiGe Si • Approaches: Ultra Compact light source & integrated photonics Nano Fluidic Circuits • Critical Challenges Semiconductor Manufacturing at a crossroads 50 nm resolution limit Lacking 3D capability State of Art • IRG II. Hybrid Top-down and Bottom-up Manufacturing Dimension below 20 nm → High density devices 3D complex nanostructures → Low power, high speed Heterogeneous integration → Multiple functionality • Plasmonic Imaging Lithography (PIL) • Ultra Mold Imprinting Lithography (UMIL) Plasmonic Imaging Lithography 8 4 Utilizing plasmonic lens on air bearing slider platform to achieve highthroughput maskless lithography Mission: Develop sub-20 nm 3D nano-manufacturing Enable the industrial quantum-leap Address work force crisis through innovative education program Etching Ultra Molding Impring Lithography use epitaxially grown superlattices to make 1-10 nm molds in 2D applications that require molecular level resolution. • Goal • Massive and parallel integration of heterogeneous nano-LEGOs into devices • Approaches • Hybrid Top-down and Bottom-up Manufacturing 40 nm 20 10 Imprinting 100 mm 100 nm 4nm imprinted features SINAM logo with the line width ~150 nm Micro/nano Fluidics Materials issues at very small dimensions: Surface plasmon: The Electromagnetic wave that propagates along the interface of metal and dielectric layers, with reduced wavelength to the order of several nanometers. Mask Demonstrate sub-100 nm features on a 170 nm period through aluminum hole array mask using 365 nm wavelength light. Education/Outreach Dendrimer molecules as “molecular pixels” Silicon and carbon for etch resistance O O O O O O Si O O Bio-Chip Si Si Si Si O O Addressing & Data acquisition Si O O O O Si Si O Si Integrated assembler system will bridge the multifunctional nanoLEGOs onto bio-MEMS devices and lead to scalable and cost effective manufacturing at macroworld. Assembly Motherboard O Cl Chemical linker Discover Nanotechnology (Grades 7-12) MS HS 100 mm Inquiry based modules • See and feel the Nanoworld → Nanomanipulator • Graduate teaching fellows, Teachers in training • Piloted in Los Angeles and Oakland [Ho, Caflisch, Chen, Maynard, Stoddart, UCLA; Majumdar, UC Berkeley; Heller, UCSD] [Yablonovitch, Osher, UCLA; Zhang, Fréchet, Grigoropoulos, UC Berkeley] Nano-Manufacturing Summer Academy/REU UG Connecting to research • High school students, teachers, undergraduates • Short courses, lab experience, competitions, internships Interdisciplinary Curricula GR • Undergraduate → Intro to NanoMfg, design projects • Graduate → New course modules based on SINAM research IRG III. System Engineering • Critical Challenge • Scale-up new nano-manufacturing processes for high throughput and high yield 3D Nano-CAD • Goal Graduate Young Investigator–You’re the PI! • • Proposal competition (5 pages) among all graduate students from five SINAM schools • Graduate student brings 2+ faculty from different disciplines • Funding for innovative research project • Approaches Develop Nano-manufacturing tool Design Nanomanufacturing Cluster Tools Machine Design Design for nano-manufacturing Tooling and metrology 3D Solid Model Decomposed Layouts UNCC 3D Sub-atomic Measuring Machine Collaborative Network Multiscale Alignment and Positioning System(MAPS) Dynamic Positioning Control Fabricated Structures Fabrication Simulators Predicted Structures Real time Feedback & Calibration Industrial Consortium (IBM, HP, Eastman, Boeing, Rockwell, Nanomix, RAND, LG Electronics..) Government laboratories/institutes (Sandia, JPL, LBNL, NIH) Business Partners (RAND, Los Angeles Regional Technical Association) International Institutions (UK, German, Netherlands, Japan, Korea, China) Device Performance Test Nano-CAD 0.9 0.6 0.3 0 -0.3 1 X (nm) Predicted Device Performance Nano-CAD Development Fabrication The interactive design interface, 3D nanoCAD, will allow efficient interactions between product design and process development. 0.3nm step 0 Electromagnetic, Thermodynamic Simulators 2 Time (s) 3 4 5 Imprinting Module • Nanomanufacturing Platform [Tsao, Chen, Hahn, Lavine, UCLA; Dornfeld, Zhang, UC Berkeley; Prinz, Goodson, Stanford; Hocken, UNCC] NSF Nanoscale Science and Engineering Center Supported primarily by the Nanoscale Science and Engineering Initiative of the National Science Foundation under NSF Award Number CMMI-0751621 . © Copyright 2008 Center for Scalable and Integrated NAnoManufacturing