Evan Stepper - WoodShopRocks

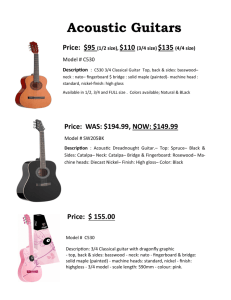

advertisement

The first step of building an electric guitar is to choose a long piece of 2 inch thick alder wood with a minimal amount of knots or flaws visible. Then select the template that matches the type of guitar you wish to build. Trace ½ of the guitar template onto one side of the wood bringing the centerline of the template all the way to the edge of the plank, over sizing it by ¼ of an inch. Repeat this tracing process with the other half of the guitar. Make sure you leave some extra room for when the guitar is table sawed. Now put on some safety goggles and bring the plank of wood with your guitar traced on it over to a chop saw or radial arm. Line up the wood with the blade, turn on the saw and slowly, but surely bring the blade through the wood. Make sure you stand to the side a little in case saw dust shoots out. Once you have both half's of your guitar sliced into two individual planks, bring them over to the table saw. Since this blade is especially sharp you may want to have an adult or supervisor help you. Straight line the wood, which means removing all of the rough wood from the outside edges. Check to see if the two pieces of wood fit together snuggly, if they do prepare to glue them together, if not keep straight lining until the two planks fit together nicely. Now get some carpenters glue and two large clamps. Put three lines of glue onto the inner side of one of the planks of wood and smear it across the wood evenly. Then while making sure the pressure doesn’t cause the boards to slip, clamp them together. After the boards have stayed glued for about 30 minutes you can remove the clamps. Next, redraw the template line onto the wood keeping in mind to line up the centerlines. Draw the template on at the exact size, ( no need to oversize it this time). Get those safety goggles back on and head over to the band saw. You are now ready to move on to cutting out the design of your guitar. Set your body down on the cutting deck and once the blade is running push your guitar body through the blade, over sizing the cut by 1/8 of an inch. Try to get through cutting the body with the least amount of cuts possible, that way the body will be smoother. Keep in mind that the thinner the blade, the more it can bend, making it easier to cut out more complicated guitar bodies. Now that piece of wood you started with is beginning to take shape. Find the template of the guitar you are building and get two screws and drill the template onto your guitar body lining up the centerlines. Bring it over to an adult or supervisor and they will exterior route your guitar body which means cutting the wood down to the exact size with a clean cut. Be careful and stand back because the router will send woodchips flying. Next grab a carpet square and a palm sander and get ready for a lot of sanding. Once the wood feels fairly smooth flip it over and sand the opposite side. If your guitar has straight sides, you can palm sand the edges as well. Otherwise take your guitar over to the spindle sander and slowly rotate your guitar body around the sander. Now that the wood is nice and smooth, grab an interior routing template and some safety goggles. Clamp the template down with the guitar onto the table, lining up the top of your guitar’s neck pocket to the three inch mark on the template. With supervision place the plunge router on top of the template. Start it up and plunge the router down and lock it with 1/5 of an inch increments each time while routing in a clockwise direction. Take the router down to the first nail for the neck and pickup cavities. Then flip your guitar over and screw on the electronic cavity template, and route all the way to the lowest nail this time. The routing does seem intense, but you will get used to it. Blow all the sawdust out of your guitar and cut the electronic cavity lip and if you wish go ahead and round the edges of your guitar. Then grab the palm sander as well as a 120 grit, 220 grit, and a 320 grit piece of sandpaper. Start with the lowest grit and sand every part of your guitar body and then repeat with the 220 and 320 grit sandpaper. Next get a neck plate and line it up with 1/8 of an inch extra wood on each side of the neck pocket. Then grab a drill and at a slight inward angle drill a hole into the wood. Now grab a hook and hang up your guitar proudly because you are ready for clear coat. Grab a paint sprayer and apply your first clear coat onto your guitar, being sure to cover the entire guitar evenly. Wait about a half hour to let it dry and then you will feel that your guitar is very rough. The clear coat has raised up the rough areas of your guitar. Now with 400 grit sand paper sand out the clear coat until your guitar is smooth again. Make sure you have sanded everywhere because the next clear coat should seal the job. You may wish to have someone experienced apply the next clear coat since that is the last step before painting. Once again, pick up a paint sprayer and choose the color scheme you want on your guitar. I will use my guitar design as an example. First spray the whole guitar black and let it dry. Then place a line of tape on the top and bottom of the side of the guitar all the way around the body. Once the tape is placed correctly place some red paint in the shooter and shoot red paint evenly over the whole guitar body. Keep in mind that the heavier the coat of red is the brighter the red will be. If you want a dark tone of red only spray a thin coat of red paint over the black layer. After the paint has dried you can peel off the tape and you will have a red guitar with black binding. Now that your guitar has the paint job you want, it’s time to give it the finishing touches. Shoot a clear coat over your painted guitar and once it has dried grab a sheet of 1500 grit sand paper and rub the clear coat smooth. Do not be worried if the paint seems to get smeared or rubbed to a dull color, the clear coat ill bring it back to life. IF the body is very smooth it is time to shoot the final clear coat onto the body. Once the clear coat dries our guitar should look shiny and feel smooth. Now that it’s time to get started on your neck, get a long plank of maple wood and on the chop saw cut out a 36 inch long section. Then cut off an 8 inch piece so you have a 28 inch and 8 inch piece. Bring both planks over to the table saw and give them both more clean cuts. Line up the grains of the wood opposite each other and place the 8 inch piece on one side on top of the 28 inch piece. Grab some carpenters glue and 4 large pipe clamps and smear some glue on the bottom of the small piece. Then while keeping the two pieces aligned as much as possible clamp the two pieces together and let it dry for an hour. Now it is time to angle your headstock. Basically that means cutting it so that it is slightly bent backwards. Set down your neck so that the smaller piece of wood is facing upwards and on the right side of the neck. The first line you should draw should be a straight line that continues from where the smaller piece of wood’s inner edge is. Using a ruler or other straight edge, draw a line from the top right corner of the small piece to the lower left corner of the same piece. Then draw a parallel line from the lower right hand corner of the smaller piece to bottom corner of the first line you drew. Take your neck over to a band saw and make a rough cut just outside of the lines your drew on the headstock. Then take the headstock over to a belt sander and sand only the front side of the headstock smooth. Next take the neck to a table saw and plow a hole for the trust rod. Basically all that means is you cut a groove down the middle of the neck with the table saw blade. Then obtain a truss rod and a chisel. With the chisel carve into the sides of the groove near the top so the head of the truss rod will firmly sit in the groove you've cut out. Once the truss rod is in proper position, use a piece of tape on the top and bottom to hold the rod down. Then cut some of the sides of the neck out so that it is thinner and centered on the truss rod. The next step is to cut out a plank of rosewood to us a fret board that is about 1/6 of an inch thick. Take it over to another radial arm and grab the fret stencil and tape your piece of rosewood to the stencil. Then one by on move the fret board into the designated position and cut out each fret slot with the radial arm. Only cut out the first 23 slots and leave the rest blank. With a sander sand off the first slot since it is not needed. Then grab carpenters glue, 4 large pipe clamps, and 4 c-clamps. Smear glue all over the fret board and glue it on top of the neck, lining it up to the center of the truss rod. Then lay it face down on the table and clamp it down using two large clamps in the middle, and one on each side. With the c-clamps placed in between them. Now attach the neck template to the bottom of your neck and take it over to the table router. Then carefully and under supervision get a nice clean cut so that the neck has an accurate shape. Now head over to the belt sander and get ready to radius the fingerboard. First hold the face of the fingerboard against the belt sander an then slightly tilt it up and down so that the fingerboard is slightly rounded. Then grab the template that you want for your headstock and trace it on so it is lined up with the fingerboard. Cut this out on the band saw, with a very close cut since you will not be routing this. Get a container of lemon oil and rub a light coat of it over your fingerboard. This helps bring some life back into the wood so the pounding of the frets wont damage the wood. Then get two strands of fret wire and bend them a little to fit the fingerboard properly. Then get a hammer and wire cutters. Position the fret wire into the first slot and hammer it in. Then cut it off from the rest of the wire. Do this for all of the frets. Once all frets are in place, bring your neck over to the belt sander and hold the side of the neck to the sand paper until the overhanging wire is filed away. Then tilt the neck both ways so that the frets are filed down to an inward position. The next step may seem a bit hard at first but you will get used to it quickly. So grab a grinder and one large pipe clamp. Clamp the end of the neck to the table upside down and mark off the spot to the seventeenth fret. Now turn on the grinder and move it across the edge of the wood on both sides so they start to get rounded. Keep grinding all the way down to the edge of the fingerboard until the whole back of the neck is rounded. Round it down until your fingers can comfortably reach other while your hand is around the neck. Then get a palm sander and thoroughly cover the back of the neck with it until all grooves are gone. Clear coat the neck and then sand it off using 400 grit sandpaper. Since you only have a rough cut of your headstock so far take a palm sander and use it on the sides of your headstock until you feel the headstock is shaped properly. Then draw a line ½ inch in from the side of the headstock. After that draw dashes every 15/16 of an inch up the line. Now take your neck over to a drill press and make sure you hold the neck firmly in the crook of your arm. Be careful because the drill can pull the neck out of your hand if you don’t hold it firmly. Once the neck is in position bring the drill press all the way in and then all the way out of the headstock for all 6 holes. After this using a band saw cut off some of the back of the headstock and about ½ inch into the grinded area. This will give the neck a more of a clean finish. Your almost done but the next step is to get your frets ready for play action. First grab a chisel and run it up and down the neck over all the frets so the shinier medal is exposed. Then use a sanding block with 320 grit sand paper to wear down the frets a little more. Now get a 3 sided triangular chisel and rub it along the corners of the frets so the medal on each side angles inward. This makes the fret feel and look much smoother. Get the 320 grit sandpaper again and this time place your fingers on top of it and move it across the fingerboard several times. If you wish to, you can add dots on the side of the fingerboard with some white paint. Finally use a chalk hardener and a chalk shiner and evenly coat it over the fingerboard. The final step for your neck is to put a final clear coat over it, do not spray the fingerboard though since it has already been shined and sealed. If you wish to have you neck painted you can apply a paint design and then use the same steps you did with your body to down the paint and then clear coat again. Now your neck should look shiny feel smooth and be ready to play on!