Assignent 4.doc

advertisement

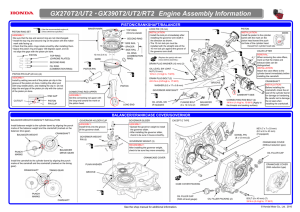

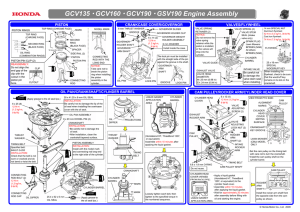

Addis Ababa University Addis Ababa Institute of Technology Department of Mechanical Engineering Thermodynamics I (M eng 2102) 1. Assignment 4 In a manufacturing facility (Figure 1), 5-cm-diameter brass balls [𝜌 =8522 𝑘𝑔/𝑚3 ] and Cp=0.385 KJ/(kg.0C)] initially at 1200C are quenched in a water bath at 500C for a period of 2 minutes at a rate of 100 balls per minute. If the temperature of the balls after quenching is 740C, determine the rate at which heat needs to be removed from the water in order to keep its tempearature constant at 500C. Figure 1 2. A piston-cylinder device initially contains 0.15 kg steam at 3.5 Mpa, superheated by 50C. Now the steam loses heat to the surroundings and the piston moves down, hitting a set of stops at which point the cylinder contains saturated liquid water. The cooling continues until the cylinder contains water at 2000C.Determine (a) the final pressure and the quality (if mixture), (b) the boundary work (c) the amount of heat transfer when the piston first hits the stops, (d) the total heat transfer. Figure 2 3. A closed steel bottle (Fig. 3) contains carbon dioxide at -200C, X=20% and the volume is 0.05m3. It has a safety valve that opens at a pressure of 6 Mpa. By accident, the bottle is heated until the safety valve opens. Find the temperature and heat transfer when the valve first opens. Figure 3 4. A rigid tank A of volume 0.6m3 contains 3kg of water at 1200C, and rigid tank B is 0.4 m3 with water at 600 Kpa, 2000C. They are connected to a piston/cylinder initially empty with closed valves as shown in Fig. 4. The pressure in the cylinder should be 800Kpa to float the piston. Now the valves are slowly opened and heat is transferred so that the water reaches a uniform state at 2500C with the valves open. Find the final volume and pressure, and the work and heat transfer in the process. Figure 4 5. The following data are for a simple steam power plant as shown in Fig.5. State 6 has X 6=0.92 and velocity of 200 m/s. The rate of steam flow is 25 kg/s, with 300 KW of power input to the pump. Piping diameters are 200mm from the steam generator to the turbine and 75 mm from the condenser to the economizer and steam generator. Determine the velocity at state 5 and the power output of the turbine. Figure 5

![VALVES, CINCH-POUND] FEDERAL AIR VENTING,](http://s2.studylib.net/store/data/012073112_1-0daf68cf64b4b9697f50564a731fe883-300x300.png)