Current Status in Germany

KEMCO International Cogeneration Symposium

Seoul, 25.09.2003

Lindenberg-Anlagen, Germany

T. Wieck

25.09.03

www.lindenberg-anlagen.de

1

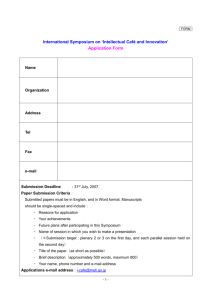

International Cogen Symposium Seoul, 25.09.2003

Presentation Contents

Technical Developments and Operation

Instances in Germany

01 Current Market Situation of Cogeneration in Germany

02 Emissions: Regulations and Technology

03 Technological Trends

04 Installation Instances

25.09.03

2

International Cogen Symposium Seoul, 25.09.2003

1. Current Status

Current Status in Germany: until 1997

more than 10.000 cogeneration units installed

more than 300 gas turbines in cogen applications installed

5000

4500

4000

3500

3000

2500

2000

1500

1000

500

0 bis

1985 bis

1986 bis

1987 bis

1988 bis

1989 bis

1990 bis

1991 bis

1992 bis

1993 bis

1994 bis

1995 bis

1996 bis

1997

Cumulated number of installations

25.09.03

3

International Cogen Symposium Seoul, 25.09.2003

1. Current Status

Current Status in Germany: 1998 - 2002

no impulse from revised cogeneration laws kW electrical installed new

120000

100000

80000

60000

40000

> 2000 kWel

50 - 2000 kWel

< 50 kWel

20000

0

1998 2001 2002

25.09.03

4

International Cogen Symposium Seoul, 25.09.2003

1. Current Status

Governmental Support:

1.) Taxation:

Ecological Tax (new since 1999):

Tax on Consumption of electrical energy

to motivate consumers to reduce energy consumption: current tax rate

(since 01.01.2003): EUR 0.0205 (Won 27) per kWh for consumed energy, if installation exceeds 2000 kW. Also in case of self-produced energy.

Tax on mineral oil & natural gas consumption

current tax rate (since 01.01.2003): EUR 0.0205 (Won 27) per liter on light fuel, EUR 0.00366 (Won 4.8) per kWh on upper heating value of nat. gas, also on heavy fuel oil.

Conventional mineral oil Tax:

EUR 0,00184 / kWh (2,4 Won) on natural gas

Energy produced by Cogen units is exempted from these taxes

Heat & power produced in conventional manner: extra taxes apply, heat & power produced by CHP: not taxed.

Production companies are exempted, too

contradiction to CHP support, but politically inevitable.

5 25.09.03

International Cogen Symposium Seoul, 25.09.2003

1. Current Status

Governmental Support:

2.) Cogeneration Law: higher prices for grid exported cogen power

Goal of European Community

To increase the percentage of electric power from cogeneration plants up to 50 MW el from 11% in 1998 to 18% in 2010.

German Implementation

Cogen Law (since 01.04.2002): payments for exported cogen power:

“Market price” (own production or purchase price paid by grid operator)+

- Avoided grid operation cost +

- Additional incentive 2.56 Cent (Won 33) per kWh

Heating load, not electrical load, should be the limiting factor

Degressive incentive to 75% in 2010 to encourage technical development

Refinancing by increase of prices for all customers

25.09.03

6

International Cogen Symposium Seoul, 25.09.2003

1. Current Status

German Building & Energy Market Structure:

Only few large apartment buildings

large east German apartment complexes connected to district heating

low electricity prices due to highly integrated European HV network

(ETSO European Transmission System Operators) – cheap sources of electricity from France, eastern Europe are offering at the German market and huge overcapacities.

In contrast: Korean situation much more advantageous to CHP applications

25.09.03

7

International Cogen Symposium Seoul, 25.09.2003

2. Emissions

New “TA-Luft” (German Regulations on Emissions) since 01.10.2002:

Emission limits for reference 5% O

2

ín exhaust gas:

NO x

: 500 mg/Nm³ for lean-burn gas engines, 250 mg/Nm³ else

1000 mg/Nm³ for Diesel engines < 3MW only possible at high SCR costs – practically not feasible, Diesel cogeneration will be terminated

CO: 300 mg/Nm³

No limits for modules for emergency use or peak load.

For comparison:

Old TA-Luft was 250 mg/Nm³ for NO x

, technical disadvantages for leanburn engines

Now: Differentiation by combustion technology

25.09.03

8

International Cogen Symposium Seoul, 25.09.2003

2. Emissions

Comparison: Limits in Korea:

Seoul now:

NOx: 100 ppm @ 13% O

2

= 410 mg/Nm³ @ 5% O

2

Korea now:

NOx: 500 ppm @ 13% O

2

= 2050 mg/Nm³ @ 5% O

2

Korea & Seoul from 01.01.2005:

NOx: 50 ppm @ 13% O

2

= 250 mg/Nm³ @ 5% O

2

25.09.03

9

International Cogen Symposium Seoul, 25.09.2003

2. Emissions

25.09.03

10

International Cogen Symposium Seoul, 25.09.2003

2. Emissions

Emissions Control:

Lambda 1 engines (rich burn):

Emission reduction is a secondary measure

Not combustion related

Depends only on size of 3-way-catalyst.

No problem to achieve NO x values of 50 ppm

Marginal cost (< 1000 Euro for engines < 400 kW)

Lambda 1 engines commonly only up to approx. 250 kWe with high speed engines

25.09.03

11

International Cogen Symposium Seoul, 25.09.2003

2. Emissions

Emissions Control:

Lambda 1.6 engines (lean burn):

Typically turbocharged

Lambda 1.5 (open chamber) or 2.2 (pre-chamber)

The emission reduction depends on the combustion (primary measure)

Lower NO x temperature requires higher lambda values to reduce the combustion

Difficult to reach 50 ppm

Loss of power higher specific investment

Loss of efficiency higher gas consumption and higher CO

2

Reduced lifetime of spark plugs and cables

Close to combustion limit, unstable operation

Higher CO output

No data available, no approval output

Only secondary measure to reduce NO x is SCR-catalyst (SCR = selective catalytic reduction), increases costs by 20 - 30%

12 25.09.03

International Cogen Symposium Seoul, 25.09.2003

2. Emissions

Example: Lindenberg CHP 300

NOx NOX Mech.

Power mg/Nm³

500

250

205 ppm

122

61

50 kW m

340

324

310*

Mech.

Efficiency

%

35.2

34.2

33.2*

CO

2 in 10 years

(30,000 MWh el

) tons

17,800

18,300

18,800

* Estimation

25.09.03

13

International Cogen Symposium Seoul, 25.09.2003

3. Technology Trends

Higher Engine Efficiencies:

Upcoming engine developments:

increased mechanical engine efficiency

no concessions on lifetimes or emissions

no concessions towards availability

Research towards:

CFD studies on internal combustions process

exhaust gas recirculation EGR

mixture formation, mixture control systems

l – control (AFR control) optimization

engine electronic control systems

higher cylinder numbers per engine – mechanical limits

higher engine outputs, espcially at high speeds

25.09.03

14

International Cogen Symposium Seoul, 25.09.2003

3. Technology Trends

Non-Engine Technologies:

Besides traditional piston engines:

Micro Gas Turbines

advantageous for small load demands (German consumer structure)

still efficiencies low - currently only research / prototype projects available

Stirling engine

low emissions

various fuel possibilities (e.g. wood pellets)

low electrical efficiency

Fuel cells

low emissions

low electrical efficiency

low longtime reliability,

difficult conversion of natural gas to hydrogen (e.g. due to sulfuric odoring contents – which is a safety feature)

Common Disadvantage: High Investment Costs

15 25.09.03

International Cogen Symposium Seoul, 25.09.2003

3. Technology Trends

CHP Developments:

Based on conventional gas piston engines:

Micro CHP

advantageous for small load demands (German consumer structure)

low power to heat ratio

Combined Heating & Cooling with Absorption chiller units:

adaptation to different consumer requirements in winter / summer season, zero heat dissipation in summer

25.09.03

16

International Cogen Symposium Seoul, 25.09.2003

3. Technology Trends

Combined Heating & Cooling with Absorption chiller units:

1.500.000 €

1.000.000 €

Investment Costs

Hotel 1000 Beds

Chiller

Boiler

Heating Unit

Absorption Cooler

Cogen Modul

500.000 €

0 €

Chiller Cogen+Cold Water

25.09.03

17

International Cogen Symposium Seoul, 25.09.2003

3. Technology Trends

Combined Heating & Cooling with Absorption chiller units:

Operating Costs

Hotel 1000 Beds

600.000 €

Maintenance

Gas

El. Power

400.000 €

200.000 €

0 €

Chiller Cogen+Cold Water

25.09.03

18

International Cogen Symposium Seoul, 25.09.2003

3. Technology Trends

Combined Heating & Cooling with Absorption chiller units:

Life Cycle Cost

Hotel 1000 Beds

7.000.000 €

6.000.000 €

5.000.000 €

4.000.000 €

3.000.000 €

2.000.000 €

1.000.000 €

0 €

0 1 2

Chiller

KWKK

3 4 5 6 7 8 9 10

25.09.03

19

International Cogen Symposium Seoul, 25.09.2003

3. Technology Trends

Electrical Aspects on Cogen Units:

Grid Stabilization by grid parallel cogen operation:

Decentralized power generation

less vulnerable to grid failures (New York 2003)

Grid relief

Emergency Power functionality in case of grid blackout

Grid parallel operation standard application in Germany

25.09.03

20

International Cogen Symposium Seoul, 25.09.2003

3. Technology Trends

Example on grid parallel operation:

25.09.03

21

International Cogen Symposium Seoul, 25.09.2003

3. Technology Trends

Potentials of Advanced CHP Control Systems:

Optional features of PLC based control systems:

Tariff based control

Joint operation of several locations with remote control, supervision and assistance: modem access, mobile phone access, Internet access

Integration of CHP module control into general building control systems (bus connection).

Korean language support

25.09.03

22

International Cogen Symposium Seoul, 25.09.2003

3. Technology Trends

Example of Advanced CHP Control:

25.09.03

23

International Cogen Symposium Seoul, 25.09.2003

3. Technology Trends

Goals & Plans:

Mid & long-term development goals, strategies:

climate protection, energy ressource protection

Current R&D situation:

Increased maintenance intervals, status based maintenance

CFD based research on piston engine technology

CFD based research on combustion processes in general

Lindenberg approach:

standardized CHP units based on well proven material with long reference lists, with service

no prototype testing

flexibility on electrical side: control features, grid connection, emergency power

Lindenberg developments focused on control systems

24 25.09.03

International Cogen Symposium Seoul, 25.09.2003

4. Installation Instances

Stages of a typical CHP project:

1.

Identification of Potential Project

2.

Data Acquisition

3.

Feasibility Study

4.

Go-No Go Decision

5.

Detail Engineering

6.

Inquiries

7.

Order

8.

Installation

9.

Commissioning

25.09.03

25

International Cogen Symposium Seoul, 25.09.2003

4. Installation Instances

25.09.03

Product Range of Lindenberg CHPs

2500 kW

2000 kW

Power

Heat

1500 kW

1000 kW

500 kW

0 kW

CHP 40 CHP 65 CHP 120 CHP 220 CHP 300 CHP 400 CHP 600 CHP 800 CHP 1000 CHP 1400 CHP 2000

26

International Cogen Symposium Seoul, 25.09.2003

4. Installation Instances

CHP 400 Unit for a Public Pool and District

Heating System (Germany):

25.09.03

27

International Cogen Symposium Seoul, 25.09.2003

4. Installation Instances

Turboblower for Sewage Plant (China):

25.09.03

28

International Cogen Symposium Seoul, 25.09.2003

4. Installation Instances

Direct Drive in Cogen Technology

Screw Compressor for Heat Pump (Northern Germany)

25.09.03

29