Presentation Slides

advertisement

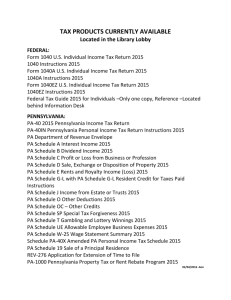

Materials in Nanotechnology E SC 213 © 2013 The Pennsylvania State University Unit 1 An Introduction to Colloidal and Self-Assembled Materials Lecture 2 Self-Assembly © 2013 The Pennsylvania State University Outline • Review of Solutions • Colloids and Colloidal Chemistry • Self-Assembly © 2013 The Pennsylvania State University Solutions • A homogeneous mixture of two or more substances • Most common: – Solid dissolved in liquid – Mixture of two liquids – Gas dissolved in liquid • There are other types as well (solid-solid, gas-solid, etc.) © 2013 The Pennsylvania State University Solution Definitions solvent molecule Homogeneous Solution solute molecule Solvent: The substance that dissolves the solute; usually the primary component Solute: The compound (e.g., salt or sugar) that is dissolved in the solvent © 2013 The Pennsylvania State University Properties of Solutions, Solutes, and Solvents Solutions • Concentration: reported in several ways – Mass basis: – Molar basis: wt% = mass of solute mass of solute + mass of solvent Molarity (M) = Moles of Solute Liters of Solution • pH: a measure of the H+ concentration in an aqueous solution. – High pH = basic; low pH = acidic – pH is a log scale, not linear © 2013 The Pennsylvania State University Properties of Solutions, Solutes, and Solvents Solutes • Ionic: dissociate into cations and anions when dissolved in a good solvent (usually water) – Examples: table salt (NaCl), NaOH • Molecular: do not dissociate; remain as whole molecules in solution – Examples: sugar (sucrose), ethylene glycol © 2013 The Pennsylvania State University Properties of Solutions, Solutes, and Solvents Solvents • Each solvent has its own set of properties – melting point – boiling point – polarity – density – index of refraction – possible impurities – health and safety Solvents are chosen for a particular application based on these factors. Goal: Find the best one for the job while minimizing risks. © 2013 The Pennsylvania State University Properties of Solutions, Solutes, and Solvents • Rule of thumb: “Like dissolves like” – This mainly applies to the polarity of solvents vs. solutes. • For example, which solvent is better suited to cleaning vacuum grease off of a glass fitting? water, acetone, hexanes • Which pairs of liquids are miscible? – water & ethanol, ethanol & IPA, methanol & hexanes, acetone & water, hexanes & pentane, water & pump oil © 2013 The Pennsylvania State University Solvent Polarity Index More Polar Less Polar Solvent Polarity Index Normal bp(°C) Water 9 100 DMSO 7.2 189 Acetic Acid 6.2 118 Ethanol 5.2 78 Methanol 5.1 65 Chloroform 4.1 61 Isopropanol 3.9 82 Methylene chloride 3.1 40 Diethyl ether 2.8 35 MTBE 2.5 55 Toluene 2.4 110 0 35,69,98 Pentane, hexane, heptane © 2013 The Pennsylvania State University Properties of Solutions, Solutes, and Solvents Other properties of solvents that may be important to particular applications: – Halogenated or non-halogenated – Aromatic vs. non-aromatic – Hydrogen bonding capability – Anhydrous (dry) or not (trace water) – Volatility – Residues left after evaporation – Ability to be sublimed – Stability: ethers decompose over time to form explosive peroxides © 2013 The Pennsylvania State University Outline • Review of Solutions • Colloids and Colloidal Chemistry – What is a Colloid? – Types of Colloids and Examples – Properties and Applications • Self-Assembly © 2013 The Pennsylvania State University What is a Colloid? The term colloidal refers to a state of subdivision, implying that the molecules or particles dispersed in a medium have at least one dimension roughly between 1 nm and 1 μm. http://goldbook.iupac.org/ © 2013 The Pennsylvania State University Comparative Size Scale Proteins HIV Virus 100 nm White Blood Cell 12-15 um E. Coli 0.8-2 um All of these could be classified as colloidal particles Red Blood Cell 6-8 um Colloidal Particles Nano-Scale 1 nm 10 nm Meso-Scale 100 nm 1 μm 10 μm 100 μm 1000 nm = 1 μm 1 nm 5 nm 10 nm 100 nm © 2013 The Pennsylvania State University General properties of Colloids • 2-phase systems: colloids have a dispersed (internal) phase and a continuous (external) phase • Large interfacial area between the two phases, due to small dimensions of the dispersed phase • Colloidal particles “are all surface” • Therefore, surface effects dominate volume effects © 2013 The Pennsylvania State University Dispersed Phase Continuous Phase General properties of Colloids • The particles are not molecularly dissolved in the medium (solvent) • Colloid ≠ solution • When properly stabilized, the colloidal particles do not aggregate or settle out over time • Colloids can be any combination of the three states of matter, but the most common colloidal mixtures consist of solid (or liquid) particles suspended in a liquid medium © 2013 The Pennsylvania State University Naming of Colloids Dispersing Medium Solid Solid Solid Liquid Liquid Liquid Gas Gas Dispersed Phase Solid Liquid Gas Solid Liquid Gas Solid Liquid Colloid Name Solid sol Gel Solid foam Sol Emulsion Foam Solid aerosol Aerosol Paul Davies, School of Chemistry, University of Bristol http://www.chm.bris.ac.uk/webprojects2002/pdavies/ © 2013 The Pennsylvania State University Examples of Colloids Dispersed Phase Continuous Phase Type Example Liquid Gas Aerosol Fog, Hairspray Liquid Liquid Emulsion Salad Dressing Liquid Solid Solid Emulsion Pearl, Opal Solid Solid Solid Suspension Pigmented Plastics, Stained Glass Solid Liquid Sol or Paste Ink, Toothpaste Solid Gas Aerosol Inhalers, Smoke Gas Liquid Foam Fire Extinguisher, Soap Suds Gas Solid Solid Foam Pumice, Styrofoam http://www.rsc.org/ chemistryworld/Issues/2003/February © 2013 The Pennsylvania State University Experiment: Finely Dividing a 1 cm3 Cube Steps 1. Start with a cube 1 cm on each side 2. Cut it into thin sheets only 10 nm thick 3. Then cut each sheet into 10 sticks 4. Finally cut each stick into nm sized cubes Calculate • Total number of pieces arising from original cube • Surface area of each smaller piece • Total surface area of all pieces • Note: volume remains constant (1 cm3) http://www.du.edu/~jcalvert/phys/colloid.htm © 2013 The Pennsylvania State University Experiment: Finely Dividing a 1 cm3 Cube Starting Volume (Not Colloidal) Laminated: Colloid Platelets Fibrillar: Colloidal Fibers Corpuscular: Colloidal Particles 1 x 1 x 1 cm 1 cm x 1 cm x 10 nm 1 cm x 10 nm x 10 nm 10 nm x 10 nm x 10 nm 1 106 1012 1018 Surface area per piece (m2) 6 x 10-4 2 x 10-4 4 x 10-10 6 x 10-16 Total surface area (m2) 6 x 10-4 200 400 600 Dimensions Number of pieces SA of all pieces needed to make up original volume Surface area to volume ratio increases as size of particle decreases. Colloids are almost all surface area! http://www.du.edu/~jcalvert/phys/colloid.htm © 2013 The Pennsylvania State University Properties of Colloids The small size of colloidal particles lends them interesting properties, including: – They scatter light (solutions do not) – The particles are subjected to Brownian motion – The surfaces of particles may become charged, depending on the medium – Charged colloidal particles can be moved (separated) by an electric field (e.g., electrophoresis of DNA and proteins) © 2013 The Pennsylvania State University Scattering of Light by Colloidal Particles Attenuation = Reduced intensity of light passing through a sample due to absorption and scattering. Homogeneous solutions do not scatter light. Colloidal suspensions do scatter light. Initial Beam Intensity (I0) Final Beam Intensity (I) Light scattered in all directions Colloidal Particles Homogeneous Solution Attenuation due only to absorption of light by molecularly dissolved species (chromophores) in the solution Attenuation due to scattering of incident light by colloidal particles. Absorption may also occur © 2013 The Pennsylvania State University DLS: Dynamic Light Scattering Laser Relative Amount • The scattering of light by colloidal particles can be put to good use • Measurements of scattering intensity versus time can be correlated to the Brownian motion of colloidal particles • Mathematical analysis of the signal is used to calculate the speed of the particles as they diffuse through the sample • The speed is related to particle size: On average, small particles move faster than larger ones Colloidal Particles Scattered Light Particle Size (nm) Detector © 2013 The Pennsylvania State University http://www.malvern.com/ Colloidal Particles in Nanotechnology Polymer molecules dispersed in solvent Proteins and DNA in biotechnology Dendrimer: starshaped polymer Metal NP Polymer nanospheres Shell NP: hollow organic, inorganic, or metal sphere Liposome: hollow particle made from lipids © 2013 The Pennsylvania State University Emulsion Formation of Colloidal Particles Physical Methods • Grinding or milling Condensation Methods • Flame-spray • Liquid phase synthesis Roller Mill Precursor Material Ball Mill Growing Particle © 2013 The Pennsylvania State University Example: Formation of Gold Nanoparticles Sodium Citrate HAuCl4 Red Color = Gold NP HAuCl4 Gold NP Heat 1. Heat a solution of chloroauric acid (HAuCl4) up to reflux (boiling). HAuCl4 is a water soluble gold salt 2. Add trisodium citrate, which is a reducing agent 3. Continue stirring and heating for about 10 minutes • During this time, the sodium citrate reduces the gold salt (Au3+) to metallic gold (Au0) • The neutral gold atoms aggregate into seed crystals • The seed crystals continue to grow and eventually form gold nanoparticles http://mrsec.wisc.edu/Edetc/nanolab/gold/index.html J. Chem. Ed. 2004, 81, 544A. © 2013 The Pennsylvania State University Example: Formation of Gold Nanoparticles Reduction of gold ions: Au(III) + 3e- → Au(0) Nucleation of Au(0) seed crystals: Seed Crystal 10’s to 100’s of Atoms Growth of nanoparticles: Isotropic Growth Spherical Nanoparticles Surface capped with citrate anions Seed Anisotropic Growth Nanorods © 2013 The Pennsylvania State University Adding surfactant to growth solution caps certain crystal faces and promotes growth only in selected directions Stabilization of Colloids • Remember: An important aspect of colloidal engineering is the suspension of the particle in a medium – often water • Colloidal particles can be hydrophobic or hydrophilic. • Hydrophilic groups generally contain oxygen and nitrogen. They are water loving • Hydrophobic colloids can be prepared in water only if they are stabilized in some way. The lack of affinity for water will cause them to settle or float • More general terms are lyophilic (likes the external phase) and lyophobic (dislikes the external phase). These terms are used when the medium is not water © 2013 The Pennsylvania State University Stabilization of Colloids How do the particles remain suspended in solution? • For such small particles, the forces of Brownian motion exceed the force of gravity, which otherwise would cause the particles to settle out • Particles suspended in water often acquire a negative surface charge. Particles with charged surfaces repel each other at short distances • Steric repulsion can also be used to keep particles from aggregating. This is useful for suspending neutral particles in non-polar continuous phases Electrostatic Repulsion + + + - + + - + + - - - - - - + + + + - + + + + - - --- - - + + - - + - - Steric Repulsion + + + + + + + + + + © 2013 The Pennsylvania State University + + Separating Colloids: Electrophoresis Colloidal particles commonly take on a negative surface charge when dispersed in water. In the presence of an electric field, the particles move through the surrounding medium. Smaller particles move faster than larger particles. Over time, the colloidal particles become separated according to size Applications: DNA fingerprinting and protein isolation/purification ++++++++++++++ ++++++++++++++ ++++++++++++++ smaller particles Power Supply --------------Sample 1 Sample 2 Sample 3 Samples added to gel and voltage applied --------------Sample 1 Sample 2 Sample 3 --------------Sample 1 Negatively charged particles migrate slowly towards the (+) electrode © 2013 The Pennsylvania State University Sample 2 larger particles Sample 3 End point: Particles separated by size Purifying Colloids: Dialysis Application: Removing impurities from a colloidal suspension. Impurities could be unreacted starting materials, by-products from particle synthesis, salts, excess capping agents, etc Dialysis Bag x x x x x x x x x x x x x x Semi-permeable membrane allows small molecules to pass. Colloidal particles are too large to pass through the membrane pores. Continuous rinsing with fresh solvent eventually removes all unwanted small molecule impurities © 2013 The Pennsylvania State University Outline • Review of Solutions • Colloids and Colloid Chemistry • Self-Assembly – What is it? – Forces and interactions – Examples from nature – Nanotechnology examples © 2013 The Pennsylvania State University What is Self-Assembly? • Ever-evolving definitions • Sometimes called self-organization • One possible definition: a reversible process that involves pre-existing, distinct components of an initially disordered structure • Therefore, self-assembly ≠ formation “Self-Assembly at All Scales,” G.M. Whitesides and B. Grzybowski, Science 2002, 295 (5564), 2418. © 2013 The Pennsylvania State University More on Self-Assembly • Has origins in organic chemistry: structures are determined bond-by-bond, but the structures are molecules (less than about 0.5 nm in size) • However, it is impossible to direct the formation (bondby-bond) of larger nano- and micro-scale structures • Lithography is very useful for building larger structures (~100 nm to microns), but is inherently a 2-D process. 3D structures have to be built layer-by-layer • Self-assembly fills the processing gap by utilizing specific (usually weak) interactions between molecules to build 2-D and 3-D structures in the 10’s to 100’s nm size range “Self-Assembly at All Scales,” G.M. Whitesides and B. Grzybowski, Science 2002, 295 (5564), 2418. © 2013 The Pennsylvania State University More on Self-Assembly • It is not a “brute-force” technique • You don’t get it by purchasing a tool from a manufacturer • In fact, it usually requires no tools at all! © 2013 The Pennsylvania State University Many things (living and non-living) spontaneously organize over many length scales: Å to light year. Å nm 10-9 10-7 10-5 mm 10-3 10-1 101 km 103 105 107 109 AU 1011 1 ly 1013 1015 1E-10-10 1E-09 1E-08-8 1E-07 1E-06-6 1E-05 1E-04-4 1E-03 1E-02-2 1E-01 1E+00-0 1E+01 1E+0221E+03 1E+0441E+05 1E+0661E+07 1E+0881E+09 1E+1010 1E+11 1E+1212 1E+13 1E+1414 1E+15 1E+1616 10 10 10 10 10 10 10 10 10 © 2013 The Pennsylvania State University 10 10 10 10 10 Forces at Work in self assembly Type or Scale of Self-Assembly Molecular Nano & Meso Scale Macro-scale van der Waals Brownian Motion Gravitation Electrostatics Capillary Forces Electromagnetic Fields Hydrogen Bonds Entropic Interactions Magnetic Interactions Coordination Bonds Self-assembly usually occurs in a fluid-like state. The materials (molecules or particles) have to be able to move around. They sample many different orientations and interactions with respect to each other. One orientation (interaction) tends to be more favorable than others. Given enough time, the structural elements optimize their local environments to produce a selforganized structure over a large volume © 2013 The Pennsylvania State University Bonding and Forces Revisited • Covalent Bonds Cl Cl • Ionic (electrostatic) - + Z Z e2 F r2 • Hydrogen Bonding • van der Waals Forces • Hydrophobic Interactions © 2013 The Pennsylvania State University F 1 r6 Competition Between Forces Often, self assembly occurs due to a competition between two types of forces or interactions. Each type of force acts over a characteristic length scale. The table below illustrates the types of self-assembly arising from the interplay of long range repulsions and short range attractions Long-Range Repulsion Short-Range Attraction Example of SelfOrganized System Hydrophobic/Hydrophilic Covalent Bonding Micelles, Lyotropic LC Incompatibility/Insolubility Covalent Bonding Block Copolymers Coulombic Repulsion Electroneutrality Ionic Crystals Excluded Volume Minimum Space Required Thermotropic LC Electric Field Electric Dipole Interaction Ferroelectric Domains Magnetic Field Magnetic Dipole Interaction Magnetic Domains “From Self-Organizing Polymers to Nanohybrid and Biomaterials,” S. Förster and T. Plantenberg, Angew. Chem. Int. Ed. 2002, 41(5), 688. © 2013 The Pennsylvania State University Examples and Applications • Simple case: crystallization of a compound from solution • For example: crystals of sugar forming when a heated sugar solution is cooled • By definition, a crystal is an ordered arrangement of components. In this case, the sugar crystals are comprised of highly ordered sugar molecules • Each sugar molecule develops specific contacts with neighboring molecules in the growing crystal © 2013 The Pennsylvania State University Example: Molecular Crystals solvent molecule (water) solute molecule (sugar) growing crystal specific intermolecular interactions © 2013 The Pennsylvania State University Inspiration from Nature More complicated examples that show the power of self-assembly: • DNA double helix – Consists of 2 strands of DNA – Each strand contains base pairs covalently bonded to a phosphate backbone – The 2 strands are held together by hydrogen bonding between complementary base pairs • Protein folding – Proteins are polymers of amino acids – They fold into intricate 3-D structures – This is discussed on the following slides © 2013 The Pennsylvania State University Example: Self-Assembly in Nature Data storage on the molecular level DNA • • • • • • • Transcription RNA Translation (Ribosome) Protein DNA sequence is the code for protein synthesis Codon: 3 adjacent base pairs of DNA that code for one amino acid in the resulting protein Side-Chain 20 possible amino acids: each has a different side-chain The side-chains have different chemical properties: large vs. small size (vdW volume and surface area) hyrdophobic vs. hydrophilic acidic vs. basic hydrogen bond donors/acceptors ability to form disulfide bonds (Cysteine: R-SH + HS-R R-S-S-R) ability to coordinate to metal atoms Side-chains help guide the protein to fold into a particular structure Proteins must be folded properly in order to perform their functions Some diseases arise from mis-folded proteins © 2013 The Pennsylvania State University Example: Self-Assembly in Nature The terminology of protein folding Primary Structure: The order of amino acids that make up the protein. They are attached, via covalent bonds, into a polymer chain Secondary Structure: Folding of the backbone chain of the protein into sheetlike or helical structures. This occurs to satisfy the hydrogen bonding capabilities of the back bone amide linkages Tertiary Structure: Packing together of secondary structure elements to form a functional protein. Hydrophobic side-chains generally pack to the inside of the protein, while hydrophilic side-chains remain on the solvent-exposed surface of the protein. The solvent here is water © 2013 The Pennsylvania State University …-Gly-Ala-Tyr-… amino acids bearing different side-chains Nanotechnology Applications • The mechanisms involved in protein folding are still being explored by molecular biologists • But, not all examples of self-assembly are so complex • In fact, scientists use much simpler versions of self-assembly all the time • Many applications have found their way into nanotech processes and devices © 2013 The Pennsylvania State University Applications of Self-Assembly Self-Organizing System Application Atomic, ionic, and molecular crystals Materials, optoelectronics Self-assembled monolayers (SAMs) Microfabrication, sensors, nanoelectronics Lipid bilayers and lipid films Biomembranes, emulsions, liposomes for drug delivery Phase-separated and ionic layered polymers Nano-structured templates Liquid crystals Displays and TVs Colloidal crystals Nanosphere lithography, photonic band gap materials “Self-Assembly at All Scales,” G.M. Whitesides and B. Grzybowski, Science 2002, 295 (5564), 2418. © 2013 The Pennsylvania State University Example: Self-Assembled Monolayers • Self assembled monolayers (SAMs) refer to the organization of extremely thin films (one molecule thick) on solid surfaces • Common examples: thiols on gold; silanes on oxide surfaces • The molecules that form SAMs are like surfactants. They have two distinct regions: One part is attracted to the surface; the other is not • The molecules are sometimes called “Ligands,” especially when talking about SAMs on metal surfaces. • Applications: improved PDMS mold release; altered hydrophobicity of surfaces © 2013 The Pennsylvania State University Example: Self-Assembled Monolayer (SAM) Octadecanethiol: C18H37-SH Surface Active Molecules van der Waals Forces Specific Interactions Metal Surface Specific example: alkane thiols on gold. These molecules have a long greasy tail and an –SH head group. The –SH is attracted to the gold while the hydrocarbon tail is exposed to the solvent or air © 2013 The Pennsylvania State University SAMs: Choosing the Best Ligand • Ligands have to be chosen so that they will bind and assemble on a surface • Some ligands work on many surfaces • Others work best only on selected surfaces • If a ligand does not bind well to a surface, then it can be easily rinsed off and a SAM does not form • When designed properly, SAMs are durable surface treatments © 2013 The Pennsylvania State University Ligands for Various Surfaces Alkylated Ligand Isonitrile R-NC Carboxylic Acid R-COOH Phosphonic Acid R-PO(OH)2 Alcohol R-OH Amine R-NH2 Amide R-CONH2 Au Zn = Yes SAM = No SAM Surface Thiol R-SH Sulfide R-S-R Phosphine R3P Cr, Ni, Fe, Al Pt Cu, Ag Other Surfaces Metal & Silicon Oxides Silanes R-SiCl3 Adsorption generally follows “Hard-Soft-Acid-Base” rules: Carboxylic and phosphonic acids adsorb onto any metal oxide surface. Thiols and isonitriles adsorb onto soft metals (Cu, Ag, Au, Pt). However, phosphines (which are considered soft) form monolayers on many surfaces (soft or hard). This could be due to their oxidation to phosphine oxides Pure and Applied Chemistry 1991, 63(6), 821-828. © 2013 The Pennsylvania State University Application: Surface Modification OH OH OH SAM + Hydrophobic Surface Hydroxyl-Rich Surface (Hydrophilic) Reacts with hydroxyls Water Drop Contact Angle and Wettability Hydrophilic <30° Hydrophobic >90° © 2013 The Pennsylvania State University Super Hydrophobic >150° Application: Microcontact Printing Liquid PDMS Precursor Cured PDMS Stamp Master Thiol Coating Gold Film Substrate Thiol SAM Gold Public Domain: Image Generated by CNEU Staff for free use © 2013 The Pennsylvania State University Example: Block Copolymers • Block copolymers are similar to surfactants in that they have two chemically dissimilar parts • When cast into films, the two blocks do not want to mix with each other (like oil and water) • But the blocks are covalently attached to each other, so they cannot move too far apart • This causes a phase separation on the nanoscale. • Nanoscale domains form a pattern that is characteristic of the block copolymer composition (spheres, cylinders, lamellae) • Changing the ratio (1:2) changes the pattern One Block Copolymer Molecule Block 1 Block 2 © 2013 The Pennsylvania State University Example: Block Copolymers Increasing Length of A One block copolymer molecule Increasing Length of B 20:80 30:70 50:50 70:30 80:20 Spheres of A Cyl of A Lamellae Cyl of B Spheres of B Structures form due to phase-separation on the nano-scale Minimization of surface area between two incompatible phases © 2013 The Pennsylvania State University Example Process for Block Copolymers The exact process route depends on the properties of the block copolymer being used to create the pattern. This example is for PS-b-PMMA, which self-assembles when heated to about 175 °C (above the Tg of both blocks, but not totally melted) • Clean the substrate to remove any contamination • Neutralize (randomize) the surface so that both blocks (PS and PMMA) have an equal affinity for the surface. In other words, neither block will preferentially wet or stick to the substrate surface • Dissolve the polymer in a solvent (toluene or PGMEA) to make a dilute solution of the polymer (1 wt% works well) • Spin coat a thin film (35 nm) of PS-b-PMMA onto the randomized substrate • Anneal (heat) the sample in a 175 °C vacuum oven for approximately 24 hours • Cool the sample back to rt and verify the self-assembled pattern via FESEM or AFM PS Block PMMA Block http://www.internano.org © 2013 The Pennsylvania State University Images of Block Copolymers 50:50 PMMA to PS Lamellae 30:70 PMMA to PS Cylinders of PMMA in a matrix of PS 100 nm Increasing size of PMMA block 70:30 PMMA to PS Cylinders of PS in a matrix of PMMA Decreasing size of PS block Overall size (PS + PMMA) remains constant Light gray: PS Dark gray: PMMA Public Domain: Image Generated by CNEU Staff for free use © 2013 The Pennsylvania State University Surfactants • Soaps and detergents are common examples of surfactants • Each molecule has a hydrophobic tail and hydrophilic head • When dissolved in water, surfactants self-assemble into micelles to minimize interactions between the hydrophobic tails and the water hydrophobic tail hydrophilic head Surfactants can be classified according to their head group: • Anionic – negative charge • Cationic – positive charge • Non-ionic – no charge • Zwitterionic – both (+) and (-) The choice of surfactant depends on the application: • Common soaps: anionic (good cleansing and high foaming) • Baby shampoo: zwitterionic (mildness) • Laundry detergent: non-ionic (lower foam and less sensitive to hardness ions) © 2013 The Pennsylvania State University Example: Micelle and Reverse Micelle Polar Solvent (Water) Non-Polar Solvent (Oil) © 2013 The Pennsylvania State University Example: Lipid Bilayers Polar Head Group Non-polar Tails Lipids are natural surfactants that selfassemble into cell membranes Aqueous Extracellular Environment Non-polar Membrane Interior Aqueous Cytoplasm © 2013 The Pennsylvania State University Liquid Crystals • Liquid crystals exist somewhere between a solid crystal (very ordered) and an isotropic liquid (no order) – Kind of like an organized liquid – The molecules arrange themselves so that they stack into a highly ordered pattern – But the material is still fluid-like • Phase change = transition from one state (arrangement of molecules) to another state © 2013 The Pennsylvania State University Liquid Crystals • Two general types of liquid crystals (LC): – Thermotropic LC: change phase as temperature increases/decreases – Lyotropic LC: phase changes induced by addition of solvent (change in concentration) • Some liquid crystals have an interesting property: they rotate the plane of polarization of light. This property is used in some LCD displays © 2013 The Pennsylvania State University Example: Liquid Crystals (LC) Thermotropic LC: change phase as temperature increases/decreases Lyotropic LC: phase changes induced by addition of solvent (change in concentration) Example of a liquid crystalline phase (there are many) Heat Liquid Crystal Long range order but still behaves like a fluid © 2013 The Pennsylvania State University Isotropic liquid no long range order Application: TFT LCD Backlight Unpolarized Light Polarizer 1 Polarized Light Self-Assembled Liquid Crystal No Voltage Applied Voltage Applied Polarizer 2 Light Passes © 2013 The Pennsylvania State University Light Blocked Example: Colloidal Crystals Similar to atomic and molecular crystals, except that the size of the building blocks are much larger and the forces holding them together are much weaker (compared to the size of the particles) Colloidal: encompasses particles that have at least one characteristic dimension in the 1 nm to 1 um range – small enough to be the subjects of Brownian motion Spherical Colloidal Crystal Colloidal Particle Closest-Packed Colloidal Spheres HIV Virus 100 nm Proteins E. Coli 0.8-2 um White Blood Cell 12-15 um Red Blood Cell 6-8 um Colloidal Particles Nano-Scale 1 nm 10 nm Meso-Scale 100 nm 1 μm 10 μm 100 μm © 2013 The Pennsylvania State University Application: Nanosphere Lithography Colloidal Solution of Nanospheres Solvent Evaporation Drop Cast Self-Assembled Nanospheres Substrate Side View Deposit Metal Dissolve Spheres Top View Feature spacing can be tailored by adjusting size of colloidal spheres © 2013 The Pennsylvania State University Summary • Colloid: refers to small size of objects; encompasses nano- and meso-scale • Colloids scatter light; homogeneous solutions do not scatter light • There are many everyday examples of selfassembly: soaps, proteins, LCDs • Emerging nanotech applications rely heavily on self-assembling molecules, polymers, and particles • Advances in self-assembly may eventually lead to true “bottom-up” manufacturing © 2013 The Pennsylvania State University