Résumé - Jade Elizabeth Bates

advertisement

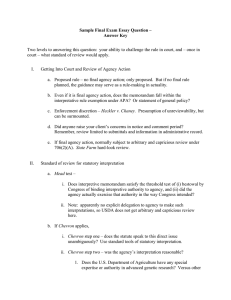

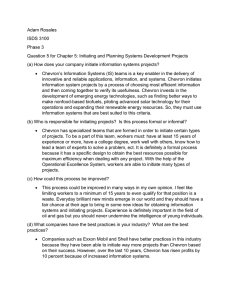

Jade Bates 6765 Corporate Blvd. Apt. 2206, Baton Rouge, LA 70809 334-507-9247 | jbate13@lsu.edu Education Louisiana State University – Baton Rouge, LA Bachelor of Science, Chemical Engineering, December 2015, GPA: 3.48 Honors: Nonresident Academic Scholar Award, Distinguished Communicator Candidate, Dr. William Brookshire Scholar, BASF Team Chemistry Award, Omega Chi Epsilon Chemical Engineering Honor Society (LSU Chapter Vice-President 2014-2015), Tau Beta Pi Engineering Honor Society Extracurricular Activities: American Institute of Chemical Engineers (AIChE), Society of Women Engineers (SWE) Work Experience Facilities Engineering Intern, May 2015 to August 2015 Chevron North America Exploration and Production Gulf of Mexico Business Unit, Operations Support – Covington, LA Oversaw cross-functional (MP313 operators, Facilities Engineering, GIS Construction, Process Engineering, turnaround coordinators) projects and utilized Chevron Project Development and Execution Process (CPDEP) MP313 Relief System Upgrades o Identified and verified relief system improvement opportunities with Process Engineering o Presented preferred alternative to Decision Review Board for team alignment and funding Granted approval on alternative and $200,000 long-lead material funding o Advanced preferred alternative: construction scoping, cost and schedule estimation, logistics o Integrated project work packs and LOTO plans into turnaround master work pack and master LOTO plan MP313 Temporary Camp Installation o Designed camp layout alternatives o Advanced preferred alternative: construction scoping, cost and schedule estimation, logistics o Granted approval on project BSEE submittal within 1 week o Conceptualized and conducted IFO session with GOM HES Specialist prior to project execution o Reinforced focus on IFO during project execution by visiting offshore and engaging crew members Achieved Incident Free project execution o Granted BSEE approval for occupancy with no further requests Presented projects to GOM FE Team Leads and Supervisors at the end of the summer Facilities Engineering Intern, May 2014 to August 2014 Chevron North America Exploration and Production Mid-Continent Business Unit, Gas Plants – Midland, TX Productively collaborated with multiple teams (Conger operators, Facilities Engineering, Process Engineering, and Odessa Pumps) and utilized Chevron Project Development and Execution Process (CPDEP) Conger Sales Facility Inlet Separator Pump Replacement o Identified pump reliability issues and generated a Basis of Design, project alternatives, and system curves then performed calculations to select and develop an alternative Presented project to MCBU FE Team Leads at the end of the summer Chemical Process Engineering Intern, May 2013 to August 2013 Occidental Chemical Corporation – Niagara Falls, NY Identified major steam consumers and condensate generators and developed process flow diagrams. Performed experimental testing and calculations to develop a salt saturation curve for the brine feed to the plant’s chlorine electrochemical cells Effectively worked and communicated with plant operators, supervisors, engineers, and lab technicians Presented projects to plant management at the end of the summer