Fluid Power (Chapter 19)

advertisement

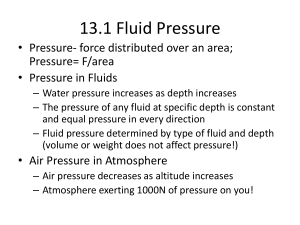

Fluid Power Control Power CVHS Fluid Power Fluid power systems are used to transmit power from one point to another They are used in many transportation devices example: brake system on a car 2 types of Fluid Power Systems: 1) Hydraulic systems are those that use a liquid, such as oil as the transmitting medium 2) Pneumatic systems use air or gas as the medium Hydraulic & Pneumatic Hydraulic fluids can not be compressed Pneumatic fluids are considered gases and are compressible Hydraulic fluids must have complete hydraulic circuits. Return lines must be used, and a reservoir is needed to hold the extra fluid (closed system) Pneumatic fluids do not need complete circuits. Air can be dumped into the atmosphere (open system) Force & Pressure Force is defined as “the pushing or pulling action of one object upon another” force usually causes an object to move usually measured in pounds Pressure is defined as “a force acting upon an area” measured commonly in psi Types of Pressure Pressure per square inch-absolute (psia) • Measure of pressure of a fluid starting at zero atmospheres and working upward to a maximum pressure • An atmosphere is a unit of pressure in which 14.7 psi of pressure is considered absolute at sea level Pressure per square inch-gage (psig) • Measures the pressure of a fluid above or below the surrounding atmosphere Pascal’s Law “A pressure applied to a confined fluid is transmitted undiminished to every portion of the surface of the containing vessel” Also states: “Pressure on a fluid is equal to the force applied divided by the area” • P=F/A – where: – P = pressure in psi – F = force applied in pounds – A = area to which the force is applied Applying Pascal’s Law Given: • Pressure = 200 psi • Force = 100 lbs Determine the Area to which the Force is Applied •P=F/A •A=F/P • A = 200 lbs / 100 psi • A = 2 in2 Boyle’s Law “The volume of a gas varies inversely with the pressure applied to it, provided the temperature of the gas remains constant” This means that as the volume of a gas is reduced such as in an engine when the piston compresses air - the pressure is increased If the volume was halved, the pressure would be doubled • Note: remember hydraulic fluids cannot be compressed, but pneumatic fluids can Charles Law “As the temperature of a gas increases, the volume of the gas increases proportionally, if the pressure is kept constant This means that as the temperature of a gas goes up, so will the volume of that gas If the temperature is doubled, then the volume is also doubled (unconfined gas) Measuring Pressure Bourdon Gage • Can read either pneumatic or hydraulic fluid pressure • Tube bends out with pressure, hook end is connected to the end of the pressure needle (mounted on a pivot) Manometer • Used to read pneumatic pressures and vacuum readings • U shaped tube with a fluid inside (fluid varies dependent upon application - i.e.: mercury used for high pressure) Fluid Characteristics Viscosity - the fluidity or thickness of the liquid at a specific temperature • Measured by a device known as a Saybolt universal viscosimeter - (SUS) Saybolt universal seconds test Viscosity Index - a measure of how much the viscosity of a fluid changes with a given temperature • Usually, the higher the VI, the smaller the relative change in viscosity with temperature Pour Point - the temperature at which the fluid ceases to flow SAE Ratings SAE - Society of Automotive Engineers ratings in viscosity they use the Saybolt universal seconds test (SUS) 10W-30 • rating with the W after it (10) means it was tested at 0oF • if no W after (30), it was tested at 210oF – thicker fluids have higher SAE ratings – sometimes a third rating is mentioned, the middle, - tested at 150oF Fluid Power Pumps Provide the pressure needed for a fluid power system to operate Hydraulic types include: Gear Pumps Centrifugal Pumps Reciprocating Pumps Pneumatic are called air compressors Use pistons to compress air (reciprocating) May be single or multi stage Usually send air to a receiver (tank) Fluid Power Conductors Provide a path for the pressurized fluid to travel Includes hoses (flexible) and lines (ridged) Must be properly sized to suit system requirements Control Devices Valves control fluid pressures, flow rates and directions Include: Pressure Relief Valves Flow Control Valves Pressure Control Valves (regulator) Directional Control Valves Fluid Power Actuators These devices put the pressurized fluid to work Cylinders are devices that use pressure to move in or out (linear) Single Acting Double Acting Motors are devices that use pressure to rotate (spin) Fluid Power storage Pneumatic: use a receiver (pressure tank) to store large volumes of pressurized air Hydraulic systems may use an accumulator to store a small amount of pressurized liquid (acts like a capacitor) Fluid Power Components & Example Circuithttp://www.patchn.com/tutr-hyd.htm Assignment Chapter 9 Questions 1-10 23-34