Document

advertisement

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

1

Lift-Safe Users' Manual

For Microsoft Excel and other Spreadsheets

Based Upon The 1991 Revised NIOSH Lifting Equation

developed by the

National Institute for Occupational Safety and Health

John C. Ratliff, CSP, CIH, MSPH

John C. Ratliff & Associates

855 NW Winged Foot Terrace

Beaverton, OR 97006

"Lotus 1-2-3" is a registered trademark of Lotus Development Corporation, 55 Cambridge Parkway,

Cambridge, MA 02142.

"Apple" and "Macintosh" are registered trademarks of Apple Computer, Inc.

"Windows" and "MS-DOS" and "Excel" are registered trademarks of Microsoft Corporation

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

2

LIFT-SAFE USERS' MANUAL ....................................................................................................................................................... 1

INTRODUCTION ............................................................................................................................................................................. 3

FIELD SAMPLING USING THE JOB STRESS ANALYSIS WORKSHEET ........................................................................... 3

HOW TO USE THIS SPREADSHEET: .......................................................................................................................................... 3

THE SPREADSHEET VERSION OF THE NIOSH LIFTING FORMULA ............................................................................... 5

HANDHOLDS (COUPLINGS) ........................................................................................................................................................ 5

THE COMPONENT CELLS ........................................................................................................................................................... 5

RECOMMENDED WEIGHT LIMIT (RWL) ................................................................................................................................ 6

THE LIFTING INDEX ..................................................................................................................................................................... 6

WHAT IS A SAFE LIFTING SITUATION? .................................................................................................................................. 6

ERGONOMIC JOB REDESIGN ..................................................................................................................................................... 7

USING THE SPREADSHEET ......................................................................................................................................................... 7

THE TWISTING COMPONENT (ASYMMETRIC MULTIPLIER) .......................................................................................... 7

HANDHOLDS (COUPLINGS) ........................................................................................................................................................ 8

PALLETIZED LOADS ..................................................................................................................................................................... 8

FORMULA & SPREADSHEET LIMITATIONS .......................................................................................................................... 9

BUT WHY ANALYZE LIFTING? .................................................................................................................................................. 9

APPENDIX 1 THE 1991 NIOSH LIFTING FORMULA ............................................................................................................ 11

THE FORMULA .................................................................................................................................................................................... 11

MEASUREMENTS ................................................................................................................................................................................ 12

FIGURING FREQUENCY AND DURATION............................................................................................................................................... 12

COUPLINGS (HANDHOLDS) ................................................................................................................................................................. 12

ASYMMETRIC, OR TWISTING, COMPONENT.......................................................................................................................................... 13

FREQUENCY TABLE ............................................................................................................................................................................ 13

CELL FORMULAS ................................................................................................................................................................................ 14

APPENDIX 2--WORKSHEET ......................................................................................................................................................... 16

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

3

Introduction

I began work on this project as a method of understanding the unique abilities of spreadsheet programs to do

the calculation work that before we had to do by hand. The spreadsheet is a tool for safety professionals,

which hasn't found it's full application to the safety field.

The use of this spreadsheet is simple. There are no calculations, only measurements. The spreadsheet does

all the calculations for you, and produces a Recommended Weight Limit for each lifting situation analyzed.

There are just eight pieces of information that must be gathered in order to use the spreadsheet, and all

distance measurements are in inches:

Weight lifted.

Horizontal distance.

Distance off the floor.

Distance lifted.

Frequency of lifting (timed with a watch, in lifts per minute)

Whether handholds are good, fair or poor.

Twisting, in degrees.

Field Sampling using the Job Stress Analysis Worksheet

The Job Stress Analysis Worksheet in Appendix 2 gives an example of the measurements, and how to get

measure them. You will need to take the following instruments:

1)

2)

3)

A tape measure

An accurate stop watch.

A scale of some sort to measure the weight of the load.

Use Appendix 2 as an example of how to measure the lifting situation.

How to Use This Spreadsheet:

This spreadsheet is to be used to calculate the NIOSH Lifting Formula Recommended Weight Limit and the

Lifting Index of up to 6 lifts. Enter the various pieces of information for the weight lifted, horizontal,

vertical, distance, frequency, twisting, and handholds' measurements from the Job Stress Analysis

Worksheet. As you enter the information, the spreadsheet automatically calculates the Recommended

Weight Limit and the Lifting Index for that particular situation.

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

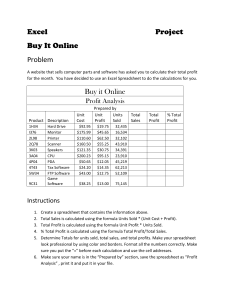

Department:

Job Title:

Analyst's Name:

Date:

4

Job Description:

Step 1. Measure the task variables and record them into the colls, either directly or with the data form (under the Data menue):

Object

Weight

L (Ave.)

25

(pounds)

L (Max)

35

Hand Location (inches)

Origin

Dest.

H orig.

V orig.

H dest.

15

32

12

V dest.

38

Vertical

Distance

(inches)

6

Asymmetric Angle

Freq. Rate

Origin

Destination

Lifts/Min.

A degrees

A degrees

Freq.

25

30

1

Step 2. Spreadsheet automatically computes the multipliers and the RECOMMENDED WEIGHT LIMITS (RWL's)

The multipliers are shown as a percentage of the ideal ideal being 100%.

RWL (lbs) =

Origin:

Destination:

LC (lbs) X

51

51

HM X

66.67%

83.33%

VM X

98.50%

94.00%

DM X

100.00%

100.00%

FM X

75.00%

75.00%

AM X

92.00%

90.40%

Step 3. The LIFTING INDEX is automatically computed:

LI Origin:

Lif ting Index =

Object Weight

RWL

LI Destination:

Lif ting Index =

Object Weight

RWL

CM

100.00%

100.00%

LI Average

Equals RWL

23.1081

27.0861

LI Maximum

Equals:

0.92

0.66

Equals:

1.08

0.77

Step 4: Analyze the Lift (see Results below and the Muliplier Gragh to right):

Results:

Look at the multipliers, and see which are lowest. These will show chiwh lif t f actors must be redesigned

(if any { to lower the Lif ting Index. The greater the percentage of the ideal f or the multiplier, the better.

Look f or the loower percentages and redesign by increasing the percentage of the ideal f or that component.

Duration

in

Hours

2.5

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

5

The Spreadsheet Version of the NIOSH Lifting Formula

This spreadsheet is oriented horizontally (see page 1), and protected. Therefore, you can only enter data in

the data form, or directly into the data cells (see below). This worksheet is set up specifically like the ones

in the NTIS book, The New NIOSH Lifting Equation. The only difference is that with this Excel

spreadsheet, no calculations need be made. The spreadsheet does it for you.

Object

Hand Location (inches)

Weight (pounds Origin

Dest.

)

L (Ave.) L (Max.) H orig. V orig. H dest. V dest.

55

65

18

15

12

30

Vertical Asymmetric Angle

(degrees)

Distance

Origin

Destin.

(in)

Distance A orig.

A dest.

15

0

0

Frequency Rate Duratio

n

Lifts/min

Freq.

2

Hours

0.5

Object

Coupling

Coupling

Good

Under “Object Couplings, you need to type in whether they are “Good,” “Fair,” or “Poor.”

Handholds (Couplings)

Handholds are another component that is included in the 1991 of the Work Practices Guide for Manual

Lifting for the first time. All that is necessary is to type in "Good," "Fair," and "Poor", and the spreadsheet

automatically calculates the percentage of ideal for the handholds. These are the "couplings" between the

object being lifted and the person's body. The definitions are fairly straightforward.

Good handholds would indicate handles of some sort. Ideally, they should be an inch to an inch and a half

in diameter, with some sort of grip. "Fair" couplings would indicate a gripping surface, where the person's

hand could get a good grip on the object to be handled. "Poor" couplings would indicate that there was no

provision for handholds, such as a large box where the grip was on the side of the box.

The Component Cells

As the data is entered for the first eight cells in the row, calculations are made, and the percentage of the

"ideal" lift will appear in these cells for each component. The numbers will vary from 100% and down.

This was done to better represent the decrease from the initial weight of 51 lbs (called a "load constant" by

NIOSH in their work practices guide). These are the factors by which the 51 LB "load constant" are

multiplied to calculate the RWL.

LC (lbs)

x

51

51

HM x

VM x

DM x

AM x

FM x

CM

56%

83%

89%

100%

94%

94%

100%

100%

91%

91%

100%

100%

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

6

Recommended Weight Limit (RWL)

This is a new term put forth by NIOSH, which indicates their recommendation for a limit on any particular

lift. It is the product of the load constant (51 lbs) multiplied by the six factors of the lift. The factors, called

"components," are shown below for three different lifts. In the 1981 formula, the prediction was that their

formula would protect 99% of men, and 85 % of women. Since the component formulas have been

changed, and made more conservative, one could conclude that the RWL will protect employees to a higher

degree.

Equals RWL in

lbs

21.51

36.35

Additionally, NIOSH is now recommending engineering controls if the lift is over the RWL. This means

that the lift must be analyzed for its hazardous components, and those changed so as to effect a less

hazardous lift (see below).

The Lifting Index

The Lifting Index was originally developed as a ratio by researchers who wanted a way of differentiating

quickly between a safe lift and one that needed controls. It is the ratio of the weight lifted verses the RWL,

and can be represented as below:

Lifting Index = Weight Lifted/Recommended Weight Limit

The lifting index is very useful, and any LI over 1.00 is considered a potentially hazardous lift. A LI over

3.00 is considered potentially dangerous, as very few people in the general population can sustain this level

of lifting without injury, and the lumbar disks are in danger in these situations.

The RWL and LI will probably be used by OSHA, at some point in the future, as a performance standard.

At this point, OSHA has begun using the 1981 Work Practices Guidelines for Manual Lifting in their

ergonomics standard for the meat packing industry. This will probably be incorporated into their general

ergonomics standard, due out soon.

The only real question is what Lifting Index they will be using for citation purposes. Whether the OSHA

people will use an LI of 1.00, or 3.00, is currently unanswered. They really haven't had time to see the new

formula as yet.

What is a Safe Lifting Situation?

The NIOSH guidelines indicate that a Lifting Index of less than 1.00 is generally a safe lifting situation.

This doesn't mean that injuries cannot occur to individuals in this situation, but that the general population is

at much less risk of injury when the LI is under 1.00.

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

7

Ergonomic Job Redesign

This is the best way to deal with lifting problems. By "ergonomic job redesign," we mean that the job must

be changed to decrease the lifting index to under 1.00. This can be done by looking at the components to

see which are the problem factors for the lift.

For instance, if the horizontal component is 49%, and it is the lowest (furthest from the idea of 1.00), then it

is the factor of the lift that needs correction. This might only be a training problem. It might also be a job

site design problem. The person doing the lifting might not be able to get close enough to the lift due to of

physical restrictions from the work place.

Using the Spreadsheet

The spreadsheet has been "protected," and therefore you have access to only the areas without formulas.

Therefore, in order to use the spreadsheet, you can enter numbers into the top cells, but only those. If you

try to change any of the others, the program will tell you that these cells are protected.

We can use the graph the various components of the lift to determine which component is causing the most

problems. Those that are the most ideal will be closest to 100%, while the components of a lift we need to

analyze will be lower:

Those components that are low are ones that should be modified for more ideal lifting. The lower the

percentage of each component, the worse the situation for that component. In completing the analyses, find

those components which need improvement, then look at the actual lifting situation. Make an ergonomic

redesign if the Lifting Index is over 3.00, and if practical, if the LI is over 1.00. This can be a improvement

in the component to make its percentage better. It can also be a complete redesign so as to eliminate the

lifting. Whatever control measure is taken, the Lifting index should be under 1.00 when completed. Note

that if the weight lifted is over 51 pounds, even ideal lifting will generate a Lifting Index over 1.00. These

jobs need to be redesigned."

The Twisting Component (Asymmetric Multiplier)

Asymmetric lifting has been a particular problem since the inception of the NIOSH Work Practices Guide

for Manual Lifting, in 1981. Because NIOSH didn't include asymmetric lifting in the original guide's

assumptions, people thought that the "ideal" lifting conditions described meant that the guide couldn't be

used for any other situations.

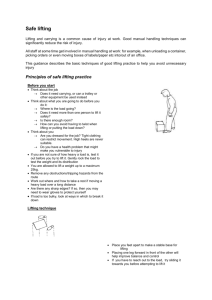

Now, asymmetric lifting (twisting) has been included. It is important that the lift be measured correctly, and

part of that is measuring the asymmetric (twisting) angle. The diagram below will help:

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

8

Midpoint

between the

Heels

H

Point

of

Projection

Angle

The angle is measured from a line drawn from the "Point of Projection" to the mid-point between the heals.

The angle is actually that which is between the sagittal plane and the line from the Point of Projection. The

object being lifted (in black above) shown, as is the line of the shoulders (shown above by the cross). The

angle between the two is what's used for the twisting angle.

Handholds (Couplings)

Handholds are another component that is included in the 1991 of the Work Practices Guide for Manual

Lifting for the first time. All that is necessary is to type in "Good," "Fair," and "Poor", and the spreadsheet

automatically calculates the percentage of ideal for the handholds. These are the "couplings" between the

object being lifted and the person's body. The definitions are fairly straightforward.

Good handholds would indicate handles of some sort. Ideally, they should be an inch to an inch and a half

in diameter, with some sort of grip. "Fair" couplings would indicate a gripping surface, where the person's

hand could get a good grip on the object to be handled. "Poor" couplings would indicate that there was no

provision for handholds, such as a large box where the grip was on the side of the box.

The first table is the "coupling multiplier" (handholds) table:

Couplings

Good

Fair

Poor

V<75 cm (30 inches)

1.00

0.95

0.90

V_75 cm (30 inches)

1.00

1.00

0.90

Using the coupling multiplier table is not necessary, because it is built into the spreadsheet.

Footing is another limitation to good lifting practices. If the ground is slippery, icy, etc., then this also

should be noted. That footing is good is a basic assumption in the guidelines. It is not currently a factor,

and will not be in the 1991 guidelines.

Palletized Loads

Analyzing palletized loads are more difficult, and an understanding of the rational used by the work

practices guideline is necessary in order to conduct such a study. Therefore, before trying this, I highly

recommend that the work practices guidelines be thoroughly studied. After such study is completed, the

spreadsheet can be used to simplify this operation.

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

9

Formula & Spreadsheet Limitations

There are limitations within the formula for each measurement. For instance, the horizontal component

cannot be less than 10 inches, as the person would be lifting within his/her own body, nor more than 25

inches, as many people cannot lift that far (the spreadsheet automatically calculates a “0%” for lifts with

reaches over 25 inches). Frequencies are in lifts per minute, and are between 0.2 times per minute and 15

times per minute. The vertical component of the lift, which the formula terms to a measure of how far

above and below mean knuckle height the lift is, is from zero to seventy inches. The distance component is

assumed to be greater than 10 inches, and less than 70 inches minus the vertical component of the lift. The

asymmetric (twisting) component of the lift is between zero degrees and 135 degrees. If the limits of any

one factor are exceeded, then you need to know that this spreadsheet might give you a false indication that

the lift is under the RWL. The lift is outside the parameters if the formula if these limitations are exceeded,

and this will not be indicated by the spreadsheet.

There is just one caution; the method by which spreadsheets accesses a table means that the information will

be at the lower level until the next level is reached. For instance, when the "LOOKUP" feature is employed

on the frequency table, it will look up the last whole number on the left column. For a frequency of 6.6 lifts

per minute, this function will return an answer of 0.27 as the multiplier (<=8 hours, V<75cm), not the next

smaller number of 0.22. This feature doesn't round to the next highest number, so the input should be in

whole numbers (rounded to the next higher when over .5)

But Why Analyze Lifting?

We do know that nationally sprain/strain injuries represent a major problem, costing several million dollars

in claims costs to employers in Oregon alone. The breakdown looks like this:

Nature of Injury or Illness

Sprains, strains

Fractures

Cuts, lacerations, Punctures

Bruises, contusions

Nervous system

Inflammation, Irritation

Multiple injuries

Dislocation

Hernia, rupture

Heat burns

1990 Claims % of Total

19,623

3,045

2,848

2,608

1,308

1,100

926

801

683

443

54.70

8.50

7.90

7.30

3.60

3.10

2.60

2.20

1.90

1.20

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

4%

2%

3% 3%

10

0%

1%

2%

8%

8%

60%

9%

The chart above shows that 54.6, or almost 60% of our injuries are sprain/stain injuries. Most of these can

be prevented. We now have a tool for analyzing lifting situations: the NIOSH Lifting Formula.

Cost information from Oregon's Department of Insurance and Finance, Information Management Section,

shows that the average cost of a sprain/strain injury in 1991 was $10,033. The total cost for sprain/strain

injuries in Oregon in 1991 was $187,623,021. The average cost of a back injury in Oregon was $10,526,

and total costs were $94,216,426 in 1991. Overexertion-type injuries amounted to $163,049,490 with the

average cost at 10,642 for each one in 1990. Although there is overlap among these classifications, it is

obvious that this represents major costs to the business of Oregon, and the United States (what is 50 times

$94 million?). It is my hope that this application will help alleviate the causes of these kinds of injuries,

make business more productive, and help make the United States more competitive economically in the

world economy.

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

11

Appendix 1 The 1991 NIOSH Lifting Formula

The formula

The actual formula used for the calculations are shown below. Be aware, this is not necessary to use the

spreadsheet. It will only help if you wish to know some of the mechanics behind the building of this

spreadsheet, and its "internal" operation. (It's like the pilot who wishes to know how the engine of the plane

works—it's nice information, but unnecessary to the flying skills of the pilot.) These are the factors for the

formula. However, you as a user of this application do not have to memorize this formula. It is

automatically calculated by entering the information into the spreadsheet.

Recommended W eight Limit = 51 lbs x HM x VM x DM x FM x AM x CM

The 1991 NIOSH Lifting Formula is a mathematical model for looking at lifting situations. Several fields of

study contributed to the NIOSH lifting formula. These fields included the study of the body in motion,

mental and social factors, how the human body works, and occupational disease research. The formula

starts with a load constant (51 lbs), and decreases the Recommended Weight Limit (RWL) downward. It

uses mathematical factors. These factors are "multipliers." For simplicity this paper will term them

"components." The load constant of 51 pounds represents the ideal lifting situation. The load constant

decreases in direct relation to the lifting component's variance from their ideal. The formula does this by

multiplying the percentage of ideal times the load constant of 51 lbs, to give a Recommended Weight Limit.

This modifies the RWL downward as the risk of injury from each component increase. Below are the

formulas for each component:

Horizontal Component:

Vertical Component:

Distance Component:

Frequency Component:

Twisting Component:

Handholds Component:

10 inches/"H" inches

1-.0075x|"V" -30 inches|

.82+1.8inches/"D" inches

From Table

1-(.0032 x angle)

From Table

25 cm/"H" cm

1-.003|V-75cm|

.82+4.5cm/"D" cm

From Table

1-(.0032 x angle)

From Table

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

12

Measurements

The measurements to be taken are defined below:

Horizontal Comp. (H):

Vertical Comp. (V):

Distance Comp. (D):

the location of the hands at origin of the lift measured forward of the body

centerline or mid-point between the ankles (in centimeters or inches).

the location of the hands at origin of the lift measured from the floor level (in

inches or centimeters).

The distance the object is lifted, determined by measuring the vertical location

of the hands at the origin and destination of the lift, and subtracting the former

from the latter.

Figuring frequency and duration

Frequency of Lifting (F):

the average number of lifts per minute. This should be timed over an extended

period so that an accurate portrayal of this variable is shown.

Duration of Lifting:

The duration of lifting affects the fatigue the muscles experience. The

frequency table breaks down the duration to lifting situations lasting less than

one hour, less than two hours, and less than eight hours. Lifting situations

lasting greater than eight hours are outside the parameters of the NIOSH

lifting formula.

Couplings (Handholds)

Handholds Comp. (CM):

The handholds on an object affect the maximum force a worker can or must

use to lift the object. Handholds are classified as "Good," "Fair," or "Poor."

NIOSH defines the three categories as follows:

"Table 1.4 Criteria for Classifying Hand-to-Container Couplings

Good

Fair

1. handles of optimal design (or)

[see note 1 below].

1. Handles of less than optimal

design (or)

2. Hand-hold cut-outs of optimal

design (and) [see note 2 below].

2. Hnad-hold cut-outs of less

than optimal design (and)

3. Containers of optimal design

with handles (see note 3 below).

3. Containers of optimal design

with no handles or hand-hold cutouts (see note 4 below).

Poor

1. Containers of less than

optimal design with no handles or

hand-hold cut-outs (see note 5

below).

1.

An optimal handle design has 1.9 to 3.8 cm (.75 - 1.5 in) diameter, >= 11.5 cm (4.5 in) length, semioval shape, 5 cm (2 in) clearance, cylindrical shape, and a smooth, non-slip surface.

2.

An optimal hand-hold cut-out has >= 3.8 cm (3 in) height, 11.5 cm (4.5 in) length, semi-oval shape, >=

5 cm (2 in) clearance, smooth non-slip surface, and >= 1.1 cm (0.43 in) container thickness.

3.

An optimal container design has <= 40 cm (16 in) frontal length, <= 30 cm (12 in) height, and a

smooth non-slip surface.

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

4.

13

A worker should be capable of clamping the fingers at nearly 90o under the container, such as required

when lifting a cardboard box from the floor.

5.

A less than optimal container has a frontal length >= 40 cm (16 in), height >= 30 cm (12 in), rough or

slippery surface, sharp edges, asymmetric center of mass, unstable contents, or require gloves."1

The Handholds (Coupling) Multiplier Table is here reproduced for ease of use of the spreadsheet program:

Handholds

Good

Fair

Poor

V<75 cm (30 inches)

1.00

0.95

0.90

V_75 cm (30 inches)

1.00

1.00

0.90

Asymmetric, or twisting, component

Twisting Comp. (AM):

Draw a line between the heels, and uses the mid-point between the heels as a

starting point. From there, draw a "point of projection" to between the hands

of the person doing the lifting. The angle is the angle ("A") is measured

between this point of projection and the line at right angles to the line of the

shoulders (the frontal plane of the body).

between the

Heels

H

Point

of

Projection

Angle

Frequency Table

There is one other table, the frequency table, which you should know about. This table is built into the

spreadsheet, and accessible by scrolling down. You don't have to know why it is set up this way to use the

formula (it is based upon a lot of physiological testing), but in case you're curious, here it is:

1NIOSH

Technical Report, "Work Practices Guide for Manual Lifting", Second Edition [Draft], U.S. Department of Health and

Human Services, Public Health Service, Centers for Disease Control, National Institute for Occupational Safety and Health,

Division of Biomedical and Behavioral Science, Cincinnati, Ohio, April 27, 1990.

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

Frequency

Lifts/Min

0.2

0.5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

>15

14

Work Duration (Continuous)

_ 8 Hours

V<30 in

0.85

0.81

0.75

0.65

0.55

0.45

0.35

0.27

0.22

0.18

0

0

0

0

0

0

0

0

_ 8 Hours

V>=30 in

0.85

0.81

0.75

0.65

0.55

0.45

0.35

0.27

0.22

0.18

0.15

0.13

0

0

0

0

0

0

_ 2 Hours

V<30 in

0.95

0.92

0.88

0.84

0.79

0.72

0.6

0.5

0.42

0.35

0.3

0.26

0

0

0

0

0

0

_ 2 Hours

V>=30 in

0.95

0.92

0.88

0.84

0.79

0.72

0.6

0.5

0.42

0.35

0.3

0.26

0.23

0.21

0

0

0

0

_ 1 Hour

V<30 in

1

0.97

0.94

0.91

0.88

0.84

0.8

0.75

0.7

0.6

0.52

0.45

0.41

0.37

0

0

0

0

_ 1 Hour

V>=30 in

1

0.97

0.94

0.91

0.88

0.84

0.8

0.75

0.7

0.6

0.52

0.45

0.41

0.37

0.34

0.31

0.28

0

Cell Formulas

Finally, it may be of advantage to some of people to know the cell formulas of this spreadsheet. These are

shown as follows:

A

B

1

1991 Formula

2

3

Weight Lifted:

35.00

These spreadsheet formulas below

are designed for Microsoft's Excel.

4

Horizontal Factor:

16.00

5

Vertical Factor:

0.00

Other spreadsheets use a similar

6

Distance Lifted:

28.00

formula system, but may need

7

Frequency :

0.20

some modifications.

8

Degrees of Asymmetry:

0.00

9

Coupling Factor from Table:

0.95

10

=IF(B4<10,1,10/B4)

11

Horizontal Multiplier:

0.63

=1-(0.0075*ABS(30-B5))

12

Vertical Multiplier:

0.78

=IF(B6<10,1,0.82+(1.8/B6))

13

Distance Multiplier:

0.88

14

Frequency Multiplier (from Table):

1.00

From Table

=1-0.0032*B8

15

Asymmetric Multiplier:

1.00

16

Coupling Multiplier:

0.90

From Table

17

=51*B11*B12*B13*B14*B15*B16

18

Recommended Weight Limit

19.66

=IF(B18<=0,"Can't Compute!",B3/B18)

19

Lifting Index

1.78

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

15

For use with Lotus 1-2-3, place an "@" sign in front of any statement (such as an @IF...), and drop the use

of the equal ("=") sign.

Please also note that either of these formulas are good for either Macintosh or IBM and compatible

computer spreadsheet programs using MS-DOS. The formulas for the frequency have since been modified,

and are much more complex. Therefore, they have not been reproduced here.

Be aware that this is a much more "primitive" method of calculating the formulas, and requires more

knowledge of the computer, spreadsheet programs, and math to accomplish. However, it does allow one to

produce the nice graphs, which are shown above.

Well, there you are, ready to go forth and look into lifting tasks. If there are other questions, please refer to

chapter 8 of the 1981 Edition of the NIOSH Work Practices Guidelines for Manual Lifting. It has some

examples to help you understand the formula. The new edition should be out soon, and when it is I feel it

would be a valuable asset for safety personnel to have and use.

I also have written a research paper on the lifting formula, titled Cracking the Knuckle Factor, or

Understanding and Applying the NIOSH Lifting Formula, which you may have by sending $5 and a

stamped, self-addressed envelope to my address.

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

16

Appendix 2--Worksheet

The worksheet is included here. This is for your use in the field. Reproduce the sheet as

much as necessary to complete you tasks.

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

17

Physical Stress Job Analysis Worksheet

Company:

Address:

Firm #:

Worker's

Name:

Task Description

Place first task here. Use the

"Tab" to go to the next column.

Highlight this text to remove it,

then press delete.

Place the second task here. Use

the "Tab" to go to the next column.

Highlight this text to remove it,

then press delete.

Place the third task here. Use the

"Tab" to go to the next column.

Highlight this text to remove it,

then press delete.

Place the fourth task here. Use the

"Tab" to go to the next column.

Highlight this text to remove it,

then press delete.

Place the fifth task here. Use the

"Tab" to go to the next column.

Highlight this text to remove it,

then press delete.

Place the sixth task here. Use the

"Tab" to go to the next column.

Highlight this text to remove it,

then press delete.

Date:

Dept.:

Job:

Claim #

Object Weight

Ave

Max.

Hand Location

h1

v1

Dist

h2

v2

Freq

03/19/16

Twist

Hand-holds

Remarks

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

18

Physical Stress Job Analysis Worksheet

Company:

Address:

Firm #:

Worker's

Name:

Task Description

Date:

Dept.:

Job:

Claim #

Object Weight

Hand Location

Ave

h1

Max.

v1

Dist

h2

v2

Freq

03/19/16

Twist

Handholds

Remarks

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

19

Lift-Safe Spreadsheet Manual, © 2015, John C. Ratliff, 3/19/16

20