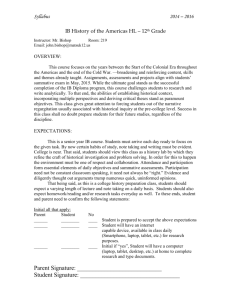

Instructions for use of Template

advertisement

Belimo Energy Valve™ Investing in Efficiency Belimo Americas Danbury, Connecticut 1 Chiller Plants Overall Energy Efficiency Manufacturer Chiller Plant Efficiency Coefficient♦ Average Chiller Plant Efficiency Coefficient♦ Actual Delta T [F] A (Office) 4.26 2.02 2.4 B (Museum) 4.78 2.87 2.8 C (Bank) 3.15 2.14 3.6 D (Office) 3.87 0.84 0.7 Plant ♦ Higher Efficiency Coefficient reflects higher plant efficiency Source: Belimo Americas Danbury, Connecticut 2 Chiller Plants Overall Electric Consumption Plant A (Office) Plant B (Museum) Pumps Avg 25.5% Chillers Avg 51% Plant C (Bank) Plant D (Office) Belimo Americas Danbury, Connecticut 3 US Cooling Energy Usage Cooling Energy Cooling Energy Other US Electric Energy Other US Residential & Commercial Electric Energy 89% 85% 11% 15% Source: US Energy Information Administration (eia) How much electricity is used for cooling in the United States? (www.eia.gov/tools/faqs/faq.cfm?id=98&t=3) Belimo Americas Danbury, Connecticut 4 Belimo Energy Valve™ is the Solution The Energy Valve is a: Pressure Independent Control Valve with an integrated Delta T Manager Belimo Americas Danbury, Connecticut 5 Belimo Energy Valve™ • • • • • • Chilled Water Plant Energy Consumption Energy Valve Benefits and Features Risk Free Investment Savings Estimator Case Studies www.energyvalve.com Belimo Americas Danbury, Connecticut 6 Pressure Independent and Delta T Manager Pump Savings in Large Tech Company in NC ♦ Pressure Independent ♦ Pressure Dependent Delta T Manager + PI 96 GPM Pressure Independent (PI) 144 GPM Pressure Dependent 240 GPM Belimo Americas Danbury, Connecticut 7 Benefits of Energy Valve • Saves on Pump • and Chiller Energy Belimo Americas Danbury, Connecticut 8 Benefits of using Energy Valve Save Energy 35 1 350 Power = kBTU/hr 300 30 2 25 Coil Power Curve 250 20 200 Delta T °F 335 330 15 150 Delta T Curve 10 12°F 10.5°F 100 5 50 0 0 0 5 10 15 20 25 30 35 40 45 GPM Belimo Americas Danbury, Connecticut 50 55 60 55 GPM 65 70 75 80 65 GPM 9 Low Delta T Cost of Overflowing the Coil… kBTU/hr GPM Pump hp 1 2 Δ 330 335 1.5% 55 GPM 65 GPM 3 Hp increase = (65/55) 18% 65% HP2 GPM 2 HP1 GPM 1 Belimo Americas Danbury, Connecticut 3 10 Low Delta T Cost of Chiller Staging Chiller Plant Efficiency Design Condition • Design delta T=12oF (54oF - 42oF) • 360 GPM • 1 Chiller, 90% Load (180 Ton) 360 GPM Loop flow Belimo Americas Danbury, Connecticut 11 Low Delta T Cost of Chiller Staging Chiller Plant Efficiency A drop in delta T causes more GPM Low delta T o • Delta T=10.4 F (52.4oF - 42oF) • 415 GPM • 2 Chillers, 45% Load (180 Ton) 415 GPM Loop flow No change to the load, but a 2nd Pump and 2nd Chiller are started. If cooling towers exist, additional cooling tower and pump may start. Belimo Americas Danbury, Connecticut 12 Features of Energy Valve • Power Control maintains coil power regardless of system variations • Built-in Energy Metering • Multiple Communication Options Belimo Americas Danbury, Connecticut 13 Power Control 0 • Power Control maintains a coil power set point regardless of pressure and temperature fluctuations Coil Power (kBTU/hr) What is Power Control ? • A control algorithm that creates a Linear relationship between control signal and kBTU/hr output 1000 Definition 0V 10V Control Signal Belimo Americas Danbury, Connecticut 14 Power Control Example 7.5 VDC = 750 kBTU/hr 750 300 3 VDC = 300 kBTU/hr 0 Example: 83 Ton AHU 83 Tons ~ 1000 kBTU/hr coil 1000 Power Control allows the controller to deliver exact energy to the space 0 to 10 VDC = 0 to 100% kBTU/hr Capacity Coil Power (kBTU/hr) • • 0V 3V 7.5V 10V Control Signal Belimo Americas Danbury, Connecticut 15 Belimo Energy Valve™ Energy Metering • By measuring Flow (Electronic Flow Sensors) and • Delta Temperature (RTD sensors) • the Energy Valve can calculate Power/Energy Power: Q (BTU/hr) = 500 x Flow (GPM) x Temperature Change (°F) Belimo Americas Danbury, Connecticut 16 Belimo Energy Valve™ Energy Metering Usage • Energy Measurement • Use as System Verification Tool during commissioning. • Establishes a baseline performance for operation over time. • Contributes to LEED. Belimo Americas Danbury, Connecticut 17 Belimo Energy Valve™ Communication Belimo Americas Danbury, Connecticut 18 Belimo Energy Valve™ Communication: Web Server • • • Energy Analysis Flow and Temperature Analysis Comparative Analysis Belimo Americas Danbury, Connecticut 19 Low Risk Investment Energy Efficiency Investing? Belimo Americas Danbury, Connecticut 20 Energy Efficiency is a Low Risk Investment Source: Laitner, J., Ehrhardt-Martinez, K. and Prindle, W., 2007, “American Energy Efficiency Investment Market”, Energy Efficiency Finance Forum, American Council or and Energy Efficient Economy . Belimo Americas Danbury, Connecticut 21 Belimo Energy Valve™ Savings Estimator Belimo Americas Danbury, Connecticut 22 Belimo Energy Valve Does it really work? Belimo Americas Danbury, Connecticut 23 Case Study MIT University Hayden Library - Boston, MA Building and Project Details • • 150,000 sq. ft. on 3 floors 6 AHU provide majority of the cooling Results • Aug 9 - Oct 9, 2010 DT = 6.15°F • Aug 9 - Oct 9, 2011 DT = 12.14°F Belimo Americas Danbury, Connecticut 24 Case Study University of Miami Hospital Building and Project Details • Rosenstiel Building • 11 AHUs • 2600 Tons of Cooling • Over 10,000 GPM Results • Delta T raised from 5.5°F to 10.5°F • Flow ~ 5600 GPM • Estimated $66,000/yr savings • Estimated 2.9 year payback Belimo Americas Danbury, Connecticut 25 Conclusion Belimo Americas Danbury, Connecticut 26 www.energyvalve.com Information and resources Belimo Americas Danbury, Connecticut 27 Belimo Energy Valve™ Thank You Belimo Americas Danbury, Connecticut 28