HVAC Presentations - Department of Mechanical and Aerospace

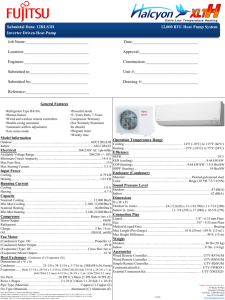

advertisement

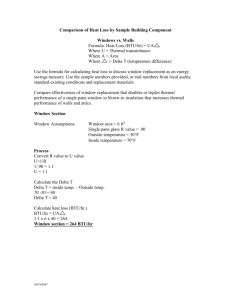

HVAC NC STATE UNIVERSITY MECHANICAL & AEROSPACE ENGINEERING MAE - 406 Douglas L. Gunnell, P.E., PEM, CEM Gunnell Engineering Services Clemmons, NC 2010-3 1 Outline Definitions Heat Transfer/Heat Generation Heating and Cooling Loads Indoor Air Quality-ASHRAE STD. 62.1 Vapor Compression Refrigeration Cycle Energy Usage Psychrometrics HVAC Systems Air-to-Air Heat Recovery Control Strategy 2 DEFINITIONS 3 Air Conditioning Process of treating air so as to control simultaneously its temperature, humidity, cleanliness, and distribution to meet the environmental requirements of the conditioned space Environmental requirements of the conditioned space may be determined by human occupancy as related to comfort and health, a process, or a product 4 Air Conditioning Processes Heating: transfer of energy to the air in a space Cooling: transfer of energy from the air in a space Humidifying: transfer of water vapor to the air in a space Dehumidifying: removal of water vapor from the air in the space Cleaning: removal of particulate and biological contaminants from the air in a space Air Motion (Circulation): movement of air through the spaces in a building to achieve the proper ventilation and facilitate the energy transfer, humidification (or dehumidification), and cleaning processes described above 5 Energy The capacity for producing an effect Either stored or transient, and can be transformed from one to another Forms include: thermal (heat), mechanical (work), electrical, chemical 6 Heat Energy in transit from one mass to another as a result of a temperature difference between two masses A basic law of thermodynamics states that heat always flows from a higher temperature to a lower temperature 7 Sensible Heat Heat which changes the temperature of a substance without changing its state 8 Latent Heat Heat which changes the state of a substance without changing its temperature Two familiar examples: latent heat of fusion (changing ice to water) and latent heat of vaporization (changing water to vapor) 9 British Thermal Unit - BTU A measure of the quantity of heat energy Heat energy in a BTU is that required to raise the temperature of a pound of water 1º Fahrenheit 10 Heat Energy Flow Rate Rate of heat loss/heat gain associated with buildings Also associated with applied heating and air conditioning equipment Normally stated in the terms BTU/hr 11 HEAT TRANSFER/ HEAT GENERATION 12 Heat Transfer Movement of heat through surfaces and openings of a building Usually assumed to be steady state (various temperatures throughout a system remain constant with respect to time during heat transmission) Based upon predetermined temperature differences 13 Heat Loss/ Heat Gain Heat Loss – heat transferred from the interior of a building to its exterior Heat Gain – heat transferred from the exterior to the interior of a building 14 Heat Transfer Modes Three modes of heat transfer: Conduction, Convection, Radiation Usually all three modes occur simultaneously In some instances, the methods can be separated, but in others, only the combined effect can be determined 15 Conduction Conduction is the transmission of heat through solids and composite sections such as structural components Conduction does not occur only within one object or substance, it also occurs between different substances that are in contact with one another By building the walls and roofs of a building of materials having known conductive characteristics, the heat flow rate for the building can be controlled 16 Convection Convection is the transfer of heat due to the movement of a fluid: gases, vapors, and liquids If the fluid moves because of a difference in density resulting from temperature changes, the process is called natural convection or free convection If the fluid is moved by mechanical means (pumps or fans), the process is called forced convection 17 Radiation Radiation is the transfer of heat through space by energy carrying electromagnetic waves Radiant heat passing through air does not warm the air through which it travels All objects absorb and radiate heat The amount of radiant heat given off in a specified period of time is dependent on both the temperature as well as the extent and nature of the radiating object 18 19 HEATING & COOLING LOADS 20 Factors that Determine Building HVAC Energy Use Building configuration and orientation Building envelope construction Interior space arrangement Design temperature and humidity, indoor and outdoor Zoning criteria Equipment application and sizing Control methodologies 21 Building Cooling and Heating Requirements A function of three heat transfer components: ◦ Heat gains or losses through the building surfaces [walls, fenestration, roof, etc.] ◦ Heat gains from internal heat producing sources [lights, people, appliances, etc.] ◦ Heat gains or losses from infiltration of outdoor air through window and door cracks, floors, walls, etc. 23 Indoor Design Conditions The primary purpose of the heating and airconditioning system is to maintain the space in a comfortable and healthy condition This is generally accomplished by maintaining the dry-bulb temperature and the relative humidity within an acceptable range The HVAC Applications Volume of the ASHRAE Handbook gives recommendations for indoor design conditions for specific comfort as well as industrial applications 24 Indoor Design Conditions…cont’d ANSI / ASHRAE Standard 55-2004 ◦ “Thermal Environmental Conditions for Human Occupancy” specifies the combinations of indoor thermal environmental factors and personal factors that produce acceptable conditions to a majority of the occupants 25 ANSI / ASHRAE Std. 55-2004 Acceptable range of operative temperature and humidity 26 Outdoor Design Conditions Climate Design Information for 4422 locations throughout the world are included on the CD that accompanies the HVAC Fundamentals Volume of the ASHRAE Handbook Appropriate outdoor design conditions can be selected from this ASHRAE document in most applications; however some states dictate the outdoor design conditions in their building codes 27 Typical Brick Veneer Wall Section 28 Calculation of Overall Heat Transfer Coefficient - U U = overall heat transfer coefficient, BTU/ hr· sf· ºF R = thermal resistance, hr· sf· ºF /BTU Wall Component Thermal Resistance Stud Path (~10%) Cavity Path (~90%) Outside air film (15 mph) 0.17 0.17 Face brick (4”) 0.44 0.44 Air space (1”) 0.85 0.85 Styrofoam insulation (1”, 90ºF) 5.00 5.00 Batt insulation 0 11.00 Wood studs 4.38 0 Foil-back gypsum board 0.56 0.56 Inside air film (still air) 0.68 0.68 Total R (R+) 12.08 18.70 R = (0.10)(12.08)+(0.90)(18.70) = 18.04 U = 1 / R = 1 / 18.04 = 0.055 29 Transmission Heat Loss Through Walls, Roofs, and Glass H = A x U x TD H = heat loss, BTU/hr A = surface area of element, sf U = overall heat transfer coefficient, BTU/ hr· sf· ºF TD = design dry bulb temperature difference between indoors and outdoors, ºF 30 Transmission Heat Gain Through Walls and Roofs H = A x U x CLTD H = heat gain, BTU/hr A = surface area of element, sf U = overall heat transfer coefficient, BTU/ hr· sf· ºF CLTD = cooling load temperature difference, ºF 31 Conduction Heat Gains Through Glass H = A x U x CLTD H = heat gain, BTU/hr A = surface area of element, sf U = overall heat transfer coefficient, BTU/ hr· sf· ºF CLTD = cooling load temperature difference, ºF Solar Heat Gain Through Glass H = A x SC x SCL H = heat gain, BTU/hr SC = shading coefficient SCL = solar cooling load factor 32 Infiltration Heat Gain and Heat Loss The uncontrolled leakage of outdoor air into a building through window and door cracks, floors, walls, etc., as well as the flow of outdoor air into a building through the normal use of exterior doors [Exfiltration is the leakage of indoor air out of the building. The amount of exfiltration equals the amount of infiltration] 33 Heat Gain from Occupants Activity Typical Application Sensible Latent (BTU/hr) (BTU/hr) Seated at rest Theater 210 140 Seated, very light work Hotels, Apartments 230 190 Seated, eating Restaurant 255 325 Seated, light work Offices 255 255 Standing, walking slowly Retail store, bank 315 325 Light bench work Factory 345 435 Walking, light machine work Factory 345 695 Bowling Bowling alley 345 625 Heavy work, lifting Factory 565 1035 Heavy work Gymnasium 635 1165 34 Heat Gains from Lights • Each watt of lighting load (including both lamp and ballast) releases 3.413 BTU/hr Heat Gain from Motors • Each brake or net horsepower of motor load divided by the efficiency (including both motor and drive) releases 2545 BTU/hr H = 2545 BTU/hr x Bhp / EffM x EffD H = heat gain, BTU/hr Bhp = brake horsepower EffM = motor efficiency, decimal fraction, 0 – 1.0 EffD = drive efficiency, decimal fraction, 0 – 1.0 35 Heat Gains from Appliances and Equipment Appliances and equipment (including food prep., hospital, lab, office, etc.) normally produce significant sensible heat, and may also produce significant latent heat. To estimate the cooling load, specific heat gain data obtained from the manufacturer is preferred. However, if it is not available, recommended heat gains are published by ASHRAE and other sources. Evaluation of the operating schedule and the load factor for each piece of equipment is essential. 36 Energy Saving Opportunities Change indoor temperature and/or humidity set-points Improve building thermal envelope ◦ Apply additional thermal insulation ◦ Improve fenestration ◦ Reduce infiltration Improve lighting system efficiency 37 INDOOR AIR QUALITYASHRAE STD. 62-1 38 39 AHSRAE Standard 62.1 Ventilation for Acceptable Indoor Air Quality Acceptable Indoor Air Quality: Air in which there are no known contaminants at harmful concentrations as determined by cognizant authorities and with which a substantial majority (80% or more) of the people exposed do not express dissatisfaction 40 The Purpose of Standard 62 The purpose of the Standard, first published in 1973 – “Standards for Natural and Mechanical Ventilation”, has remained consistent: “To specify minimum ventilation rates and other measures intended to provide indoor air quality that is acceptable to human occupants and that minimizes adverse health effects.” 41 Under Continuous Maintenance… The standard is updated on a regular bases using ASHRAE’s Continuous Maintenance Procedures ◦ Continuously revised addenda are publicly reviewed and approved by ASHRAE ◦ Published in a Supplement approximately 18 months after each new edition of the Standard OR ◦ A new, complete edition of the Standard is published every three years 42 Significant Changes to ASHRAE Standard 62 1981 Edition: ◦ Reduced the minimum outdoor air requirements for ventilation Office – 15 cfm/person to 5 cfm/person 1989 Edition: ◦ Increased minimum outdoor air requirements for ventilation [Response to growing number of buildings with apparent IAQ problems] Office – 5 cfm/person to 20 cfm/person 2004 Edition: ◦ Changed the ventilation rate procedure to include the summation of two components: the occupant-density related component, and the area related component ◦ Changed the ventilation rates in Table 6-1 to apply to nonsmoking spaces 43 Significant Changed … cont’d 2004 cont’d: ◦ Added classification of air with respect to contaminant and odor intensity, and established guidelines for recirculation 2007 Edition: ◦ Updated information in Table 4-1 – “National primary ambient air quality standards for outdoor air as set by the U.S. Environmental Protection Agency” ◦ Added Section 5.18 – Requirements for buildings containing ETS areas and ETS-free areas (ETS-Environmental Tobacco Smoke) 44 ASHRAE Standard 62.1 Two alternative procedures for determining outdoor air intake rates: ◦ Ventilation Rate Procedure This is a prescriptive procedure in which outdoor air intake rates are determined based on space type/application, occupancy level, and floor area ◦ IAQ Procedure This is a design procedure in which outdoor air intake rates and other system design parameters are based on an analysis of contaminant concentration targets, and perceived acceptability targets 45 62.1-2007 46 62.1-2007 47 62.1-2007 48 62.1-2007 49 62.1-2007 50 62.1-2007 51 62.1-2007 52 North Carolina State Building Code Mechanical Code [International Mechanical Code] Energy Code [International Energy Conservation Code] 53 NCSBC 54 NCSBC 55 NCSBC 56 Noteworthy Energy Conservation Considerations CO2 based demand controlled ventilation Air-to-air energy recovery [Exhaust air stream – outdoor ventilation air stream] 57 Energy Conservation Imperative Ongoing effective maintenance program for equipment and controls 58 Commentary ASHRAE Standard 62.1 – Code Adoption ◦ Standard 62.1 is voluntary until adopted by code or other regulation ◦ Code adoption is often delayed due to time required to be accepted and integrated into the model codes, as then accepted and adopted by the local codes 59 Energy Saving Opportunities Optimize the energy requirements associated with outdoor ventilation air Apply CO2 based demand control Apply air-to-air energy recovery equipment 60 VAPOR COMPRESSION REFRIGERATION CYCLE 61 Vapor Compression Refrigeration Cycle Evaporation: Low pressure liquid absorbs heat (heat source) and changes state to a low pressure vapor Compression: Low pressure vapor is compressed to high pressure vapor Condensation: High pressure vapor is cooled (heat sink) and changes state to a high pressure liquid Expansion: High pressure liquid is reduced to low pressure liquid via throttling 62 Vapor Compression Refrigeration Cycle Components EVAPORATOR 63 Basic Liquid Chiller - Water Cooled EVAPORATOR CHILLED WATER 64 ENERGY USAGE HVAC SYSTEM ENERGY USE The energy use in a Heating, Ventilating and AirConditioning System is that associated with: The generation of heating and cooling medium – steam, hot water, chilled water, and dx refrigeration (through boilers, chillers, and dx refrigeration assemblies utilizing fossil fuels and electricity) The movement of heat transfer fluids – air and water (through fans and pumps utilizing electricity) [As in the previous sections, energy saving opportunities will be identified and discussed throughout this seminar] PSYCHROMETRICS 67 Psychrometrics The science that deals with the thermodynamic properties of moist air – dry air/water vapor mixture, and the utilization of these properties to analyze conditions and processes involving moist air For the accuracy required in the majority of air conditioning problems, the perfect gas relations can be applied when calculating the thermodynamic properties of moist air 68 Psychrometrics Atmospheric air consists of a large number of gases (including oxygen, nitrogen, argon, and carbon dioxide) as well as water vapor and various contaminants Dry air exists when all water vapor and contaminants have been removed from atmospheric air Moist air is a binary (two-component) mixture of dry air and water vapor. The amount of water vapor in moist air can vary from zero (dry air) to a maximum (saturation) which depends on temperature and pressure 69 Properties of Moist Air Psychrometrics deals with the following defined properties of moist air: ◦ Dry Bulb Temperature –the temperature of a gas or mixture of gases indicated by an accurate thermometer after correction for radiation. (ºF) ◦ Wet Bulb Temperature – thermodynamic wet bulb, temperature is the temperature at which liquid or solid water, by evaporating into the air, can bring the air to saturation adiabatically at the same temperature. (ºF) ◦ Dew Point Temperature – the temperature at which the condensation of water vapor begins for a given state of humidity and pressure as the temperature of the vapor is reduced. (ºF) 70 ◦ Relative Humidity–the ratio of the mol fraction of water vapor present in the air, to the mol fraction of water vapor present in saturated air at the same temperature and barometric pressure. (%RH) ◦ Humidity Ratio– Ratio of the mass of water vapor (steam) associated with one pound mass of dry air. (Lbmw/Lbmda) or (Grainsw/Lbmda ) [Also referred to as Specific Humidity] ◦ Enthalpy– thermodynamic property of a substance defined as the sum of its internal energy plus the quantity PV/J, where P=pressure of the substance,V=it’s volume, J=mechanical equivalent of heat. (Btu/Lbmda) [Also referred to as total heat and heat content] 71 ◦ Specific Volume–the ratio of the volume of the mixture to one pound mass of dry air (Ft³/Lbmda) ◦ Vapor pressure– the pressure exerted by a vapor. If a vapor is kept in confinement over its liquid so that the vapor can accumulate above the liquid, the temperature being held constant, the vapor pressure approaches a fixed limit called the maximum, or saturated vapor pressure, dependent only on the temperature and the liquid. (In. Hg) 72 PSYCHROMETRIC CHART The Psychrometric Chart is a graphic representation of the thermodynamic properties of moist air. To minimize the complexity of the chart, the air component is a fixed value - per pound of dry air. Dr. Willis Carrier is credited with the development of the psychrometric chart in 1911. There are a number of psychrometric charts, defined by dry-bulb temperature ranges. 74 75 76 Sling Psychrometer Battery Operated Psychrometer Digital Psychrometer 80 81 82 83 84 85 PSYCHROMETRIC CLASS PROBLEM In an office, the following measurements were made with a sling psychrometer, 70ºF dry-bulb, and 58.5ºF wet-bulb. From a normal temperature psychrometric chart, determine the following thermodynamic properties: Dew Point Temperature Humidity Ratio Relative Humidity Enthalpy Specific Volume CLASS PROBLEM SOLUTION Dew Point Temperature: 50.6ºF Humidity Ratio: 54.6 Grains/Lbm Relative Humidity: 50% RH Enthalpy: 25.33 Btu/Lbm Specific Volume: 13.5 Ft³/Lbm 88 89 90 91 92 93 94 PSYCHROMETRIC CLASS PROBLEM Field measurements from an industrial air handling unit cooling and dehumidification section (spray-type air washer) indicated the following: CFM: 71,000 Entering Air Conditions: 84.4ºF dry-bulb, 71.4ºF wet-bulb Leaving Air Conditions: 63.5ºF dry-bulb, 63.0ºF wet-bulb Determine the following: Entering Air Enthalpy (h): Btu/Lbm Leaving Air Enthalpy (h): Btu/Lbm Total Cooling Capacity: Btu/Hr & Tons Psychrometric Equations HT = HS + HL HT = Total Heat, BTU/Hr HS = Sensible Heat, BTU/Hr HL = Lateral Heat, BTU/Hr HS = (1.08)(CFM)(∆t) HL = (0.68)(CFM)(∆W) HT = (4.45)(CFM)(∆h) HT = (500)(GPM)(∆t) CFM - Volumetric airflow rate, Ft2/Min ∆t - Temperature differential, ˚F ∆W - Humidity ratio differential, Grains/Lb. ∆h - Enthalpy differential, BTU/Lb. GPM - Volumetric water-flow rate 97 CLASS PROBLEM SOLUTION Entering Air Enthalpy (h) = 35.1 Btu/Lbm Leaving Air Enthalpy (h) = 28.5 Btu/Lbm (From Psychrometric Chart) HT = (4.45) (71,000) (35.5 – 28.5) = 2,085,270 Btu/Hr HT = 2,085,270 Btu/Hr ∕ 12,000 Btu/Hr Ton = 173.8 Tons Continuity Equation Q = VA Q = Volumetric flow rate, Ft3/Min V = Average velocity, Ft/Min A = Cross-sectional Area, Ft2 99 HVAC SYSTEMS 100 Developing an HVAC System Basic System Requirements Provide heating Modulate heating to satisfy variations in load Provide cooling Modulate cooling to satisfy variations in load Provide adequate ventilation Provide air cleaning (filtration) Control humidity (humidify/dehumidify) Integrate with other building systems 101 Developing an HVAC System Critical Consideration Issues Environmental Control Requirements ◦ Occupant Comfort ◦ Clean Air / Ventilation ◦ Product / Process Requirements Equipment Fuctionality ◦ Reliability while meeting requirements Economics ◦ Initial Cost ◦ Operating Cost ◦ Maintenance Cost 102 HVAC System General Classification All-Air Systems Air-and-Water Systems All-Water Systems Unitary Air Conditioners 103 HVAC System Definitions All-Air System ◦ Provides complete sensible and latent cooling capacity in the cold air supplied by the system ◦ No additional cooling is required at the zone ◦ Heating can be accomplished by the same airstream, either in the central system or at a particular zone Air-and-Water System ◦ Conditions the spaces by distributing air and water sources to terminal units installed in habitable space throughout a building ◦ The air and water are cooled or heated in central mechanical equipment rooms ◦ The air supplied is called primary air, the water supplied is called secondary water 104 HVAC System Definitions All-Water System ◦ Heats and/or cools a space by direct heat transfer between water and circulating air Unitary System ◦ Packaged air conditioning units with integral refrigeration cycles 105 All-Air Systems Single zone draw-through Constant volume terminal reheat Dual-duct Multizone Variable air volume (VAV) 106 General Air Handling System Layout 107 Air Side Economizer Modes: Free Cooling Economy Refrigeration 108 Constant Volume System with Terminal Reheat 109 Dual Duct System 110 Variable Air Volume System (VAV) 111 True VAV Terminal Unit 112 Parallel Fan-Powered VAV Terminal Unit 113 Series Fan-Powered VAV Terminal Unit 114 Fan Volume Modulation for VAV Systems 116 Basic Fan Laws 1. Volume varies directly with speed ratio CFM2 = CFM1 (RPM2 / RPM1) 2. Pressure varies with square of speed ratio P2 = P1 (RPM2 / RPM1)2 3. Horsepower varies with cube of speed ratio HP2 = HP1 (RPM2 / RPM1)3 117 Fan Problem An existing centrifugal supply air fan serving a central station air washer delivers 90,000 cfm @ 2” s.p. (wg), 825 rpm and 47.3 bhp. It has been established that the volumetric air flow rate (cfm) can be reduced 20% because of excessive design safety factors and plant production equipment modifications. Determine: 1) new air volume, 2) rpm @ new cfm, 3) bhp @ new cfm, and 4) annual electrical savings Electricity cost: Demand charge - $6.00/kw (avg) Energy charge - $0.031/kwh (avg) 118 FanNewProblem Air Volume = 0.8 Solution x 90,000 = 72,000 cfm 1. 2. 3. 4. New RPM = 825 (72,000/90,000) = 660 rpm New HP = 47.3 (660/825)3 = 24.2 hp Annual electrical savings… HP reduction = 47.3 – 24.2 = 23.1 hp KW reduction = (23.1 hp)(0.746 kw/hp) = 17.2 kw Energy: (23.1 hp)(0.746 kw/hp)(8760 hr/yr)($0.031/kwh)(1.03 tax) = $4,820 /yr Demand: (17.2 kw/mo)(12 mo/yr)($6.00/kw)(1.03 tax) = $1,276 /yr Annual Electrical Savings: $4,820 + $1,276 = $6,096 /yr 119 Air and Water System Induction Fan Coil 120 Induction Unit Induction Nozzle 121 Fan Coil Unit Note: Conditioned outdoor ventilation air is delivered into the space through an independent de-coupled system 122 All-Water Systems Unit Ventilator Fan Coil 123 Unit Ventilator 124 Fan Coil Unit Note: Outdoor ventilation air provided through infiltration 125 Unitary Air Conditioners Rooftop Split System Through-the-wall 126 Packaged Rooftop Air Conditioning Units 127 Water-Source Heat Pumps 128 Water Loop Heat Pump System 129 Energy Saving Opportunities Convert air-handling systems from constant volume to variable-air-volume (VAV) airflow: employ VAV boxes and fan motor variable speed drives. [Typical target systems: constant volume systems with terminal reheat, & dual duct systems] Convert traditional multi-zone units to by-pass multi-zone units Install air-side economizers – maximize the use of outdoor air for cooling: “free-cooling” and “economy refrigeration” Eliminate the air-side economizer cycle on multi-zone units Install water-side economizers 130 Energy Saving Opportunities… cont’d Optimize/balance volumetric airflow rates and eliminate excess by fan speed adjustments Implement occupied/unoccupied scheduling Employ air-to-air heat exchangers – exhaust air heat recovery Develop and implement an effective Preventative Maintenance (PM) program Replace equipment with higher efficiency equipment. [Evaluate the employment of evaporative condensers in lieu of air-cooled condensers] Air-to-Air Heat Recovery Properly applied air-to-air energy recovery equipment, which transfers energy between supply and exhaust airstreams, will reduce building and/or process energy usage in a costeffective manner. Air-to-air energy recovery applications fall into three categories (ASHRAE): ◦ Comfort-to-comfort ◦ Process-to-comfort ◦ Process-to-process [Because of time constraints in this workshop, we will limit our discussion to comfort-to-comfort applications] 132 Comfort-to-Comfort Applications Sensible Heat Devices - only transfer sensible heat between the supply and exhaust airstreams, except when the exhaust airstream is cooled to below its dew point. Total Heat Devices - transfer both sensible and latent heat between the supply and exhaust airstreams 133 Performance Rating of Air-to-Air EnergyRecovery Equipment ASHRAE Standard 84-1991, “Method of Testing Air-to-Air Heat Exchangers”, was developed to establish a uniform testing and rating standard. e= Actual transfer for the given device Maximum possible transfer between airstreams e = effectiveness 134 Air-to-Air Heat Recovery Equipment Rotary (Heat Wheel) Heat Pipe Static Heat Echanger Runaround System 135 Rotary (Heat Wheel) 136 Heat Pipe 137 Static Heat Exchangers 138 Runaround System 139 CONTROL STRATEGY 140 Control Strategy Optimize the operation of the HVAC systems [To minimize the fan, heating and cooling energy requirements] Develop and implement system scheduling – occupied/unoccupied Implement optimal start/stop Optimize the temperature and/or humidity setpoints in both the occupied and unoccupied periods Introduce outdoor ventilation air only when the building is occupied Provide control system override 141