docx - Institute for Sustainable Manufacturing

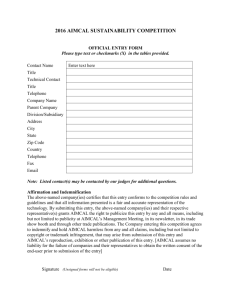

advertisement