Detergent update

advertisement

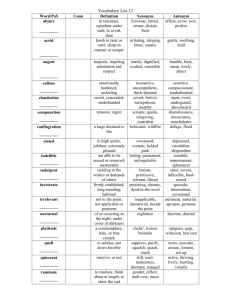

Moorepark Milk Quality Workshop 2011 Detergent update David Gleeson Introduction Detergent product list Cleaning system experiments at Moorepark Operational costs of different cleaning systems Detergent lists Product lists updated for Mar 2011 – Moorepark website-PDF format (www.teagasc. ie ) link-research & innovation/dairy) – Separate table for liquid caustic only products – List: 41 liquid detergent sterilizer & 8 liquid detergent products, 25 powder products (5 contain chlorine) & 12 liquid sterilizer products – 7 brands reformulated with higher spec – Only 32% of liquid detergent-sterilizer or sterilizer products are registered with DAFF (Jan/11) – PCS number-new column – (www.pcs.agriculture.gov.ie/biocidalproductregisterJanuary2011.pdf Important points in relation to detergent sterilizers A minimum of 800 ppm in the working solution is suggested for detergent sterilizers where the product is recycled and when hot wash is not used at each milking – Most popular washing system used in Ireland (e.g. 10% caustic @ 360mls/45 litres = 800 ppm or 18% caustic @200 mls/45 litres =800 ppm) Detergents with a lower working solution (< 800ppm) should give satisfactory cleaning when used with hot water daily and not recycled Increasing the usage rate of detergent-sterilizer products to achieve higher caustic levels may result in nonacceptable levels of chlorine in the working solution Acceptable chlorine levels in the working solution may range between 150 and 320 ppm depending on water temp (e.g. 3.5% chlorine@ 360mls/45L =280 ppm or 4.% chlorine @ 360 mls/45L =320 ppm) Chemical analyses of detergents Caustic range for detergent-sterilizers: – < 1 to 19 % – 59% of products with caustic levels below 10% Chlorine range: – <1 to 9.5% – 34% above 4.0% Important points in relation to powder detergent products A number of powder products contain acceptable levels of chlorine (20%) Working solutions for cold caustic cleaning greater than 2000ppm are recommended – lower WS when chlorine is present (800PPM) A small number of powder products are recommended to be used as hot wash only (these may also be used at lower working solutions) Some products contain high levels of sodium carbonate while other products contain high levels of non caustic alkaline detergents which have additional cleaning benefits. The usage rates of caustic only powder products may be increased to increase the working solution It is considered that all powder products analysed contain adequate caustic levels Caustic content in liquid detergent products on the Irish market (March, 2011) Product % Caustic w/w W.S* Hot wash W.S* Cold Wash Timac CIP 28.08 1747 2496 P3-mip CIP 27.7 1848 2772 Multisan CF** 25.4 1695 2542 Parlosan NC** 24.3 1623 2704 Quantum x L 22.3 558 X Alkadex Forte 20.6 1028 X Hypral SP 15.9 1059 x Sanagard 10.5 524 x * Working solutions are calculated based on manufactures recommended usage rates and % caustic measured in products ●** The addition of hydrogen peroxide to these products is recommended by manufacturers Cleaning systems trial 7 washing systems evaluated 3 week period on each of 3 farms (June –Nov) Auto-washer calibrated for each product No re-cycling of detergent for second daily wash Measurements included – TBC (n=1,800) & Thermodurics(n=800) for milk line & bulk tank milk – TCM for milk line – Bacterial swabbing: start of wk 1 and end of wk 3 claw pieces liners stainless steel Cleaning systems evaluated PRODUCT W.S Caustic ppm Water temp Usage rate mls/45L Add. product Once wk Acid Descale 1 P3-mipCIP 2,772 cold 450 2 P3-mipCIP 1,848 hot 300 3 P3-mipCIP 2,772 Cold/hot 450 daily 4 Hypral SP 1,059 hot 300 weekly 5 Liquid Gold 797 hot 250 weekly 6 Multisan CF 2,542 cold 450 hydrogen peroxide weekly 7 Parlosan NC 2,704 cold 500 hydrogen peroxide weekly weekly chlorine weekly Summary of results Treatment P3-mipCIP cold P3-mipCIP hot/chlorine P3-mipCIP-cold acid-hot Hypral SP hot Liquid Gold hot Multisan CF cold/hp Parlosan NC cold/hp TBC (average) Thermodurics (average) Tank TBC (24hr) (average) Tank Thermodurics (average) 2,181 92 (0-2,700) 14,247 161 67 (0-790) 12,814 69 39 (0-360) 6,856 59 112 (0-790) 8,165 140 90 (0-610) 5,864 86 104 (0-2,600) 11,437 252 123 (0-720) 13,635 205 (410-6700) 2,166 (190-7,200) 1,252 (180-3,500) 2,173 (110-7,100) 2,010 (210-4,300) 1,956 (400-6,300) 2,019 (230-9,400) Bacterial numbers on milk liners and stainless steel Low bacterial numbers observed on stainless steel & milk liners No significant difference for any washing system at wk 3 compared to wk 1 SS, wk1= 100cfu, wk3= 200cfu Liners, wk1=100cfu, wk3= 140cfu Increase in bacterial numbers observed on ‘plastic’ from week 1 to week 3 Week 1 Week 3 sig P3-mipCIPcold 13,000 39,000 < 0.01 P3-mipCIPhot/chlorine 7,200 27,500 < 0.05 P3-mipCIPacid 17,000 16,500 NS Hypral SPcold 52,000 70,000 NS Liquid Goldhot 17,000 45,000 NS Multisan CFcold 34,000 74,000 < 0.05 Parlosan NCcold 59,000 280,000 < 0.01 Relationship between Thermoduric count and TBC Thermoduric category 0 10-20 >20-40 50- 200 >200 No of samples 174 246 308 282 137 Average Thermoduric count 0 10 28 95 521 TBC 1,463 1,769 2,034 2,249 2,378 Milk samples taken during milking (no bulk tank samples included) Treatment PPM-Chlorine in wash solution TCM P3-mipCIP cold 0 0.000 P3-mipCIP hot/chlorine 0 0.000 P3-mipCIP acid 0 0.000 0 0.000 211 0.000 0 0.000 0 0.000 Hydral/hot Liquid Gold/hot Multisan CF/cold/p Parlosan NC/cold/p Cost of cleaning products PRODUCT Price of product used in calculations litres Descaler 58 25 P3-mipCIP 29.95 20 Boost/blast 12.5 5 68 22 37.50 20 Multisan 29 20 Parlosan 30 20 Chloras 21 25 Hypral SP Liquid Gold ESB €/litre Night-rate 0.017 Day-rate 0.0087 Source; John Upton Cost of products may vary depending on the source and may be lower if large quantities are purchased Weekly costs (€) per unit associated with 9 washing systems detergent chlorine Hydrogen peroxide Descale Acid Hot water (night Rate) Total cost 10 units Lactation (NR) Total cost 10 units Lactation (DR) P3mipCIPcold 1.89 0.00 0.24 0.08 950 982 P3mipCIPhot/ch 1.26 0.03 0.24 1.10 1128 1578 P3mipCIPacid 0.94 0.00 1.70 0.55 1372 1597 Hypral SP/hot 2.04 0.00 0.24 1.10 1452 1902 Liquid Gold/hot 1.05 0.00 0.24 1.10 1028 1477 Multisan CF/c/p 1.83 0.07 0.24 0.16 990 1054 Parlosan NC/c/p 2.10 0.07 0.24 0.16 1104 1168 LiquidGold/h/c 1.44 0.00 0.24 0.63 993 1250 Liquid gold/h/rec 0.66 0.00 0.24 0.63 658 915 Discussion All cleaning systems gave satisfactory cleaning performance when used as recommended for the period tested-longer test time may be necessary New cold cleaning systems more expensive than existing Teagasc recommended cleaning system (NR,10 units, year €658 v €1014) Cold wash systems have similar running costs as twice-daily hot detergent sterilizer systems if using NR (10 units, year €1014 v € 1028) Lowest TBC & Thermoduric levels observed with daily hot acid wash PM -but at a cost ! (NR, 10 units, year, €658 v €1372) Could reduce the usage rate of some detergent sterilizers if products have a high caustic content and if using hot water and not re-cyling solution Conclusions Increased occasions of acid cleaning and hot water usage had the biggest impact on TBC & Thermodurics Cleaning systems had no impact on TCM when used correctly Cold wash systems – Longer term evaluation – Recycling of product not evaluated Caution- Caustic only cold wash systems require contact time to be effective – suitability for bulk tank cleaning? Future cleaning system studies Evaluation of re-cycling liquid hot/cold wash detergent-sterilizers and detergent only cleaning solutions on TBC, Thermodurics & TCM residues Evaluation of using disinfectant products like peracetic acid in the final rinse water Thank You