Microorganisms of Juice: Managing Competition in the Tank

advertisement

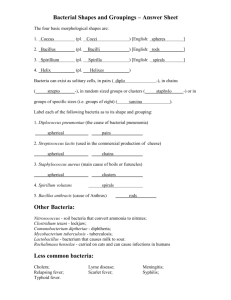

Microorganisms of Juice: Managing Competition in the Tank Lucy Joseph U.C. Davis Department of Viticulture and Enology Managed Ecosystem Ecological Succession in Wine Fermentation Which Microbes Are Found? – Vineyard to Must Factors Affecting Grape Microflora • • • • • • Moisture/Humidity Insect Vectors and Damage Temperature Vineyard Management Practices Variety of Grape Geography Environmental Conditions that Affect the Microflora of Must • • • • • pH - Low Nutrients - high sugar, variable nitrogen Temperature - fermentation creates heat Oxygen - fermentation is low oxygen Inhibitors - pesticides, sulfur, alcohol, acetic acid, etc. • Winery Practices - additions, sanitation, stylistic considerations Fungi found on Grapes • • • • • • • • Botrytis cinerea – bunch rot Plasmopara viticola – downy mildew Erysiphe necator – powdery mildew Penicillium – green mold Aspergillus – black mold Alternaria – black smut Cladosporium – post-harvest Rhizopus – soft rot Bacteria in the Vineyard Lactobacillus Lactococcus Enterococcus Weissella Gluconobacter Pediococcus Oenococcus Must Lactobacillus Pediococcus Weissella Gluconobacter Acetobacter Gluconacetobacter Leuconostoc Oenococcus Yeast in the – Vineyard Harvested Grapes Zygosaccharomyces Hanseniaspora Issatchenkia Kluyveromyces Metschnikowia Pichia Candida Rhodotorula Sporobolomyces Sporidiobolus Hanseniaspora Metschnikowia Candida Yeast Found in Must Hanseniaspora uvarum, guilliermondii, opuntiae Metschnikowia pulcherrima Candida zemplinina, glabrata, diversa Pichia anomala, fermentans, guilliermondii Clavispora lusitaniae Zygosaccharomyces bailii Kluveromyces thermotolerans Kazachstania species Issatchenkia occidentalis, orientalis, terricola Saccharomyces cerevisiae Saccharomyces in the Vineyard • Saccharomyces occurs in only about 1 sound berry in 1000 tested • In damaged berries that increases to about 1 in 4 berries tested • The number of Saccharomyces cells on damaged berries is about 104 to 105 cfu/ml • The total microbial counts in damaged berries is 106 to 107 cfu/ml Typical Saccharomyces Growth Curve vs Typical Wine Fermentation Curve 400 30.00 350 25.00 300 20.00 250 Brix 15.00 200 10.00 150 5.00 100 50 0.00 0 (5.00) 250 0.00 0 50 100 150 200 50.00 100.00 150.00 200.00 250.00 300.00 350.00 400.00 Saccharomyces and Non-Saccharomyces Growth Curves vs Typical Wine Fermentation Curve 400 30.00 350 25.00 300 20.00 250 Brix 15.00 200 10.00 150 5.00 100 50 0.00 0 (5.00) 250 0.00 0 50 100 150 200 50.00 100.00 150.00 200.00 250.00 300.00 350.00 400.00 How Certain Groups are Selected Natural selection: • • • • • • Low pH High sugar concentration – high osmolarity Other nutrients High phenolic content Low oxygen Alcohol concentration How Certain Groups are Selected Artificial Selection: • • • • • Temperature Potassium metabisulfite pH - Tartaric acid Lysozyme Nutrients What Are Some “Best Practices”? • Harvest brix less than 27o brix • Harvest acid content – pH 3.2 to 3.6, TA 0.6 to 0.8 • SO2 added at the crusher • Temperatures less than 30oC • Pump overs to manage temperature oxygen levels • Addition of nutrients only as needed Why Do Best Practices Work? What do they control? Acid Adjustment • High acid favors growth of yeasts early in fermentation • Most microbes, especially bacteria, are not acid tolerant • pH often increases during fermentation which favors the ML fermentation • pH greater than 3.6 encourages spoilage lactics • Brettanomyces is more tolerant to low pH Addition of SO2 • Inhibits the growth of spoilage bacteria • Inhibits growth of wild yeasts including Brettanomyces • Destroys thiamin • Inhibits oxidation Inoculation • Directly adds the desirable organism in high numbers Engineering Practices • Adjusting temperature – Cold soaks – Tank temperature, jacketed – Pump overs • Adjusting oxygen – Cap Management – Pump overs – Rack and return – Punch down – Stirring or aeration – Micro-ox Temperature • Cold soaks (15-20oC) encourage growth of non-Saccharomyces yeast early in fermentation • Cool temperatures during fermentation inhibit growth of spoilage bacteria and some yeasts • Warm temperatures can favor ML bacteria • Cool storage temperatures discourage spoilage organisms during storage Low Oxygen • Strict aerobic organisms cannot compete under low oxygen conditions Filamentous fungi Acetic acid bacteria • Anaerobic and facultative anaerobes grow under low oxygen Saccharomyces ML bacteria Risks and Rewards • Long hang times of fruit allow for development of desirable flavor and color and adds complexity • Over doing it results in higher sugars that can produce too much alcohol that can arrest fermentation, leave residual sugars, and leave nutrients for spoilage organisms • Acidity may also suffer and be too low allowing spoilage organism to flourish Risks and Rewards • Cold soaks can allow growth of wild yeasts that produce desired esters and other flavor compounds that add complexity • Typically yeasts like Hanseniaspora, Pichia, and Candida occur • Wild yeasts can also produce acetic acid and ethyl acetate in large amounts and this can be particularly risky with damaged fruit Risks and Rewards • Low oxygen prevents the growth of strict aerobic organisms like acetic acid bacteria and filamentous fungi • Too much oxygen allows a bloom of aerobic organisms that often occur as a film on the surface of the wine • Micro-ox done incorrectly in the presence of microbes, for example wood, results in the bloom of atypical microbes in wine Case Study 1 • A winemaker approached Dr. Bisson with a wine that had a mousey taste and low bacteria numbers by microscopic observation. No bacteria were found by plating or QPCR. • The wine was filtered and filters plated on both bacterial (MLAB) and yeast (YM and WL) media. Grenache Wine Grenache Filter on Plate What Is Causing the Contamination? • There are many sources of bacterial contamination including: air, dust or soil, grapes, wood, water, and corks. • The wines were typical except that the SO2 level was low to none. • The wines showed contamination with many species of bacteria. • All of these wines were treated by micro-oxidation in the presence of wood. What Is Causing the Bacillus Contamination? •In bottling lines, Bacillus spores can survive heat treatments that have replaced chemical sanitation measures. •Bacillus is a strict aerobe but is typically acid sensitive •Ethanol is effective at inducing sporulation in Bacillus Case Study #2 • Wine was returned from the distributor due to high turbidity. Wine had no aroma or flavor defect, only high turbidity in some bottles. • Bacteria were visible under the microscope but did not grow on plates and QPCR came back negative. What was in the wine? • Initial plating indicated Bacillus but the Bacillus didn’t look like what we saw under the microscope • It might be Bacillus spores • Looking further we also found moderately high levels of Staphylococcus pasteuri The wine • The wine was sweetened with added juice. I don’t know if the juice was filtered. • Synthetic corks were used. • The pH of the wine was high. • The bottling line was cleaned with only hot water, bleach was no longer being used. Best Practices • Developed over time because they work • How and why they work has not always been understood • Significant deviation from the best practices rarely goes well