Benko_Article_drum_oven_white_paper_FINAL

advertisement

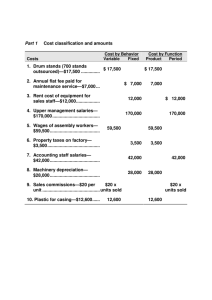

Feeling the Heat Six important factors manufacturers must consider when heating drums and totes By Laurie Benko Hull Manufacturers throughout the process industries have traditionally utilized a variety of methods to heat their drums and totes, including band heaters, immersion heaters, steam jackets and homemade, in-plant hot rooms. Over the years, operators in the chemical, food and pharmaceutical industries have turned to drum warming ovens as a safe, cost-effective way to heat those 55-gallon drums. But before a manufacturer commits to one specific technology, it’s important to understand the considerations that should go into selecting the proper heating technology for their specific needs. There are six important factors that all operators should consider prior to selecting a heating method, starting with the material that is being heated. 1. Material When heating drums and totes, it is critical to fully understand all of the characteristics of the material to be heated. Operators should consider the following questions: • Is the material flammable? • Is the material caustic or corrosive? • What happens when the material is heated? • Does the material have an autoignition temperature? • Will excessive heat burn or degrade the material? • Will heating the material produce a dangerous or foul fume or vapor? If the material is flammable, an NFPA (National Fire Protection Agency) Class A oven, hazardous duty band heater or water bath may be necessary. Caustic or corrosive materials may require special coatings or stainless steel construction. Spill containment may be needed as certain materials expand when heated. The bungs on the drum may also need to be loosened to relieve pressure caused by heating. Autoignition temperature of a material is the lowest temperature at which it can spontaneously ignite in a normal atmosphere without an external source of ignition, such as a flame or spark. The temperature at which a chemical will ignite decreases as the pressure or oxygen concentration increases. It is critical that operators take the proper steps to ensure the material being heated never reaches the autoignition temperature. Precise temperature control and temperature uniformity are critical requirements to ensuring excessive heat doesn’t burn or degrade the material. Some fragile materials, such as honey, will burn when subjected to excessive heat. Band heaters, which concentrate intense heat on a small section of the drum, should not be used. If heating the material will create a dangerous fume or vapor, operators must take steps to ensure the proper exhaust. 2. Environment Environment encompasses the area where the drum heating will take place. When considering environment, all hazards and classifications in the area must be known. If it is an explosion-proof area, the heater must be properly designed for the hazard classification. This may require the use of steam heat, hazardous duty rated heaters and NEMA 7/9 controls. Within that established environment, operators must consider whether or not the heat created by the heating of drums will impact the temperature of the room. This consideration may require the implementation of a process designed to prevent heat from escaping during the heating process. Operators can properly utilize insulated ovens with door switches to prevent heat from being blown out of the oven when the doors open, or even exhausting the oven prior to the doors being opened. Special construction and controls are necessary for use in wet areas such as outdoor applications and washdown areas. 3. Heat-Up Times A third factor to consider when heating a drum is the heat-up time. How quickly a drum must melt or reach a certain temperature will dictate the heating method to be used, as well as the quantity of drums to be heated. Certain methods produce faster heat-up times than others. For example, a prefabricated drum oven will generally melt a drum faster than a band heater. Factors to consider when predicting heat-up times include the material’s starting temperature, its melting point, specific heat, heat of fusion and the maximum temperature the material can be exposed to. A reputable supplier of drum heating equipment will be able to estimate heat-up times and may even guarantee them. 4. Energy Use Energy efficiency must be a top consideration for operators as stricter legislation has dictated the implementation of more environmentally friendly equipment worldwide. Certain methods of drum heating are more energy-efficient than others. One example would be a compact, fully insulated drum oven, which is much more energy-efficient than a large homemade, in-plant hot room. Plants will build dedicated hot rooms to heat drums. Sizes can vary greatly, but traditionally these rooms are large enough for a forklift to maneuver in and out of with ease. Some hot rooms can fit as many as 100 pallets in them but are typically inefficient from an energy perspective due to their tall ceilings and large surface areas. The entire room must remain heated, even if the space is partially full. Drum ovens, by comparison, are compact and only heat the space directly around the drum. Most in-plant hot rooms are poorly insulated as well. Temperatures fluctuate greatly due to their size and lack of adequate airflow. Doors in these hot rooms can also be left open for long periods as forklifts drive in and out, pushing heat out of the hot room and onto the plant floor. The heating medium used will also dictate energy use, and the heating medium used will depend on what is available at the plant. If an abundance of steam is available, it can be utilized as an efficient method of heating. Electricity is also convenient and efficient if the oven or hot room is properly sized, insulated, temperature-controlled and features adequate air circulation. 5. Material Handling Drum handling is very important to consider when deciding on a heating method. The entire drum heating process must be thought out to ensure the least amount of drum handling as possible. Hot drums are inconvenient and unsafe to handle and may even leak or spill when transported far distances. One way to eliminate transportation concerns would be to have the drums heated near the process they are going to be implemented. Whether the drum is simply dumped into a tank or requires a more controlled removal method, such as pumping or metering, it is convenient and practical to have the drum heater near the process. The advantage of having a drum next to its destination is that there is less handling required and less time for it to cool down. If pumping is required, it is critical to keep the drum warm as this process can take a long time. If operators choose this option, drum ovens, band heaters, drum wraps and immersion heaters are ideal. They can be located near the drum filling line, tanks or pumping station for convenience. Other considerations in the material handling process should be convenience and flexibility. Drum ovens and smaller heating methods, such as band heaters, provide greater flexibility as they can be turned off when not in use. It is also easier to heat the drums or totes to various temperatures when not utilizing a large hot room. For example, if 16 drums need to be heated quickly to 200° F, a 16-drum capacity oven can be easily set to the desired temperature. This is not an option in a large, central hot room environment where varying materials are stored. Some may not be able to take the heat. If large numbers of drums must be heated, band heaters and other single drum heaters will be time consuming and labor intensive to use. A properly sized drum oven or in-plant hot room makes more sense. 6. Cost While cost shouldn’t be a top consideration, operators must consider equipment that will perform their jobs at an economically acceptable level. Initial purchase price as well as lifetime running costs must be weighed. Plants can utilize band heaters, which represent the least expensive heating option, or they can invest in homemade, in-plant hot rooms, which represent a substantial cost to the company. It is expensive and time-consuming to build a hot room. In this process, someone is required to design it, procure the materials and then build it. There are other costs to consider beyond the initial purchase price. This includes the cost involved with downtime as various heating options aren’t as reliable as others and require frequent maintenance. Durability and dependability also tie into maintenance costs as drum heaters, for example, have a well-earned reputation for providing the reliability manufacturers demand. Conclusion When manufacturers consider methods for safely heating their valuable products, they must consider the material, heat-up times, energy use, material handling and costs. While band heaters, homemade hot rooms and immersion heaters can meet traditional heating needs, each technology has disadvantages that make them an inefficient option in many applications. Drum warming ovens have become a popular choice in industry as they offer the energy efficiency and safety other heating methods cannot, protecting employees and the environment from dangerous, ignitable vapors while providing costeffective heating in less time. Laurie Benko Hull is Sales Manager with Benko Products, Inc. She can be reached at 440-934-2180 or at lhull@benkoproducts.com. Benko Products, Inc. is a privately held company based out of Sheffield Village, OH. Benko Products was founded in 1983 by pioneer John Benko, the inventor of many breakthrough products such as the Sahara Hot Box® drum warming oven, the G-Raff Elevating Tank Truck Platform and the Protect-OGate line of Mezzanine Safety Gates. Benko Products’ leading product lines include drum and tote ovens, industrial ovens, mezzanine safety gates and chemical storage systems. Benko Products is also the parent company to GREEN Access & Fall Protection, a leading manufacturer of access and fall protection platforms and gangways for tank trucks and rail cars. For more information on Benko Products, go to www.benkoproducts.com.