How is radiation monitored at the facility?

advertisement

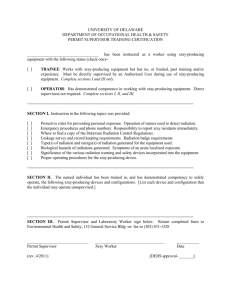

Australian Synchrotron Contractor Safety Induction Safety Team Sergio Costantin Hock Ch’ng Piers Davenport RSO Head of Safety Safety Officer Everyone at the facility is responsible for safety! Facility Layout ‘Bull Ring’ Lunch Room (mezzanine floor) Beamline Reception Beamline Crescent Area Loading Bay Area Plant Rooms Beamlines Floor (white) First Aid Control Room (not permanently staffed) (mezzanine floor) Site Access • All contractors must sign in and sign out at reception • Access cards (as required) are available at reception General safety • Smoking is permitted only in the designated outdoor areas as shown Guest House NCSS General safety • Zero blood alcohol limit while working • Illegal drugs are not permitted at any time • Enclosed footwear must be worn on the beamlines floor Emergency procedures When the evacuation alarm sounds (whooping tone): 1. Immediately leave the building by the nearest exit (emergency exits are alarmed-use only during evacuations) 2. Gather at the Assembly Point Assembly point 3. Follow the directions of the wardens (wearing hardhats) Reception Car park NCSS First aid • Seek the assistance of a First-Aider no matter how minor the injury • All injuries must be reported and recorded in the First Aid register by a First-Aider • There are a number of First Aid officers at the facility including the security guard General Safety Reporting events The incident investigation form (available from WHSE team) is used to report: • injuries • incidents • hazards • near misses Reporting of near misses helps minimise the chance of an incident or injury. Reporting events How do I deal with a safety issue? •We are all responsible for safety – if you see a simple hazard and you can fix it – do it! (then report it so preventative action can be taken) – If you can’t fix it, make area safe and get help Speak to: – your primary Synchrotron contact – the Control Room ext. 4123 – WHSE Office Warning signs and barriers • Signs will generally indicate: • hazards in an area; or • required Personal Protective Equipment • Barriers are erected around additional hazards for your protection • For your safety and the safety of others, please take appropriate actions as indicated Forklift safety • Forklifts will operate in pedestrian areas • Be aware when forklift is operating •Orange Mezzanine lights will flash; •Lab/workshop lights will stay on (not flash) Job Safety Analysis (JSA) / Safe Work Method Statement (SWMS) •All contractor work must be covered by a JSA or SWMS •All involved in the work must sign-off on the JSA/SWMS •JSA/SWMS need to be provided to WHS for review at least several days in advance of the work commencing •All equipment including Personal Protective Equipment required for the job must be provided by the contractor Permit to Work AUSTRALIAN SYNCHROTRON PROJECT: PERMIT TO WORK DOC ID: ASP-PM-0034-07.1 Permit To Work Form OH&SMP VERSION/ISSUED: Rev 0- 9 September 2005 PERMIT NO: 1. BUILDING/AREA: A Permit is required for work involving: 2. PLANT/EQUIPMENT NAME: 3. DESCRIPTION OF WORK: 4. EQUIPMENT TO BE USED? • Live plant (electrical or mechanical isolations) • Hot work (e.g. welding, cutting & grinding) • Confined spaces • Excavation • Roof Access • Any work that has the potential to activate the smoke detection system • Site safety systems, such as the Personnel Safety System (PSS), radiation shielding or fire protection systems 5. CHEMICALS TO BE USED ? (including any compressed gases) YES NO IF YES, DESCRIBE FIRE PROTECTION MEASURES 7. HAS THE FIRE SYSTEMS BEEN ISOLATED? YES NO IF YES, DETAILS: 8. CONFINED SPACE ENTRY INVOLVED? YES NO If yes, the Confined Space Entry Checklist must be completed and attached 6. HOT WORK IS INVOLVED?: ELECTRICALLY ISOLATED AND TAGS FITTED?: MECHANICALLY ISOLATED AND TAGS FITTED?: 9. PLANT ISOLATIONS: YES NO N/A YES NO N/A ELECTRICAL ISOLATION NOTICE NO. (Attached): MECHANICAL ISOLATION NOTICE NO. (Attached): E M 10. SAFETY CHECKLIST: 1. A JSA has been completed. JSA No: copy attached. 2. Has a work procedure been developed to cover the intended task/s? (attach copy) 3. Are there relevant vendor procedures? (attach copy) 4. Have appropriate barriers and warning signs been erected? 5. Has the area been made safe from debris, dust and other obstructions? 6. Are adjoining equipment/operations/work hazardous to this job? OR Is this job hazardous to adjoining equipment/operations/work? 7. Have all radiation sources been isolated or controlled? 11. OTHER PERMITS (related to this work or issued for this work area) No: Description: No: Description: No: Description: YES NO N/A CONFIRMED (initials) 12. ADDITIONAL PRECAUTIONS/ PERSONAL PROTECTIVE EQUIPMENT (PPE) The following additional precautions/PPE will be required: 13. AUTHORISATION This equipment/plantIarea is safe to perform the work described on this Permit, provided all precautions are fully observed. These precautions have been discussed with persons involved. NAME: SIGNATURE: DATE/TIME: 14. PERMIT EFFECTIVE FROM: (Date/time) 15. PERMIT EFFECTIVE TO: (Date/Time) 16. RECEIVING PERSON RESPONSIBILITY: I/we fully understand the Permit to Work procedure and all the precautions to be taken. I/we will observe the precautions specified and take any additional safety procedures necessary in line with good work practices and the Victorian OH&S Act of 2004. I/we understand the emergency procedures and know the emergency assembly area. I/we acknowledge that these precautions have been explained to me/us. I/we undertake to explain these precautions to all people under my/our charge on this work. I/we have fitted my/our personal locks to the appropriate isolations I/we agree to inform the Issuer of this Permit immediately of any changes that occur in workplace conditions that may affect this permit. NAME: SIGNATURE: DATE/TIME: 17. HAND BACK: I confirm that where necessary I have inspected the area/equipment and it has been left in a safe, clean and tidy condition. All safety tags, lockout devices I have installed have been removed and accounted for. NAME: SIGNATURE: DATE/TIME: 18. RETURN TO SERVICE All safety tags, lockout devices have been removed and accounted for. The equipment/area is ready for return to normal use NAME: SIGNATURE: DATE/TIME: ALL PERMITS ARE CANCELLED IMMEDIATELY THE FIRE/EVACUATION ALARM SOUNDS PERMITS MUST BE CLOSED by the appropriate Synchrotron personnel when the work is complete and the equipment/area deemed safe Electrical safety DANGER TREAT ALL PLANT AS LIVE . • All electrical equipment must be tested and tagged Use of ladders ALL LADDER WORK ABOVE 2 metres MUST BE COVERED BY A JSA/SWMS 900 mm from top of ladder CORRECT Preference is to use a platform ladder rather than an A-frame INCORRECT Looking after our environment •Consider ways to reduce use of – paper – water – electricity •Use recycling facilities •Limit amount of waste produced •Avoid or reduce chemical use when possible •Specific environmental issues will be raised when reviewing your JSA/SWMS Radiation and Radiation Safety at the Australian Synchrotron Radiation Producing Facility The Australian Synchrotron is a radiation producing facility. The radiation is used to gather experimental information. The Synchrotron is a source of ionising radiation only when it is running. Our aim is to ensure that all radiation doses are As Low As Reasonably Achievable (known as the ALARA principle). • Some things we use to help achieve this aim: • Personal Monitoring • Lights, signs and colour • Radiation Protection Principles How is radiation monitored at the facility? Personal Monitoring There are two ways to carry out personal radiation monitoring of individuals: • Personal monitoring using a TLD badge or Luxel • Pocket dosimeters (three types available from the Control Room) The most appropriate form of monitoring (if any) will be provided to you if required. How is radiation monitored at the facility? Personal Monitoring If provided with a badge: It must be worn at all times while at the Synchrotron; and Lost or damaged badges must be reported to the Radiation Safety Officer immediately. If provided with a pocket dosimeter: It must be worn at all times while at the Synchrotron; The details of results must be completed in the log book in the Control Room (assistance available from your primary synchrotron contact or Control Room operators); and If a dosimeter is lost or damaged it must be reported to the Radiation Safety Officer immediately. How will people be warned about radiation and radiation areas? Warning Lights (Personnel Safety System) Red Lights (normally) indicate that radiation is present, e.g. inside the accelerator tunnels or inside a beamline enclosure. How will people be warned about radiation and radiation areas? Warning Lights During the injection process of the electron beam (electron beam transferred from Booster Ring to Storage Ring) orange lights will flash at locations on and within the Storage Ring. (Not to be confused with forklift warning lights which are located under the mezzanine level.) During this period radiation levels within the facility are slightly higher than during normal operation. It is recommended not to linger of the tunnel roof when the lights are flashing. (Also use distance to help minimise radiation dose.) How will people be warned about radiation and radiation areas? Radiation Warning Signs Radiation areas display radiation warning signs. Signs of this nature are prominent throughout the facility. Other radiation controls within the facility. Other Radiation Warning Signs / Labels • Sign / label to indicate important configuration items. • Item NOT to be modified or removed without proper (written) authorisation. Other radiation controls within the facility. Warning Indicator (Paint Colour of Beamline Enclosures) • All radiation shielding panels of beamline enclosures are painted blue (aqua). • Any item in this colour must NOT be interfered with (modified or removed) in any way, without (written) authorisation. How do I minimise my radiation dose? Three Principles of Radiation Protection •There are three basic principles to protection from radiation. (1) SHIELDING (2) DISTANCE •(3) TIME Putting these principles into action will help reduce radiation received (i.e. your radiation dose). How do I minimise my radiation dose? Three Principles of Radiation Protection - Shielding •Placing adequate shielding between you and the radiation source will minimise the amount of radiation you receive. How do I minimise my radiation dose? Three Principles of Radiation Protection - Distance •Maximising the distance from a radiation source will minimise the amount of radiation you receive. How do I minimise my radiation dose? Three Principles of Radiation Protection - Time •Minimising the time you spend near a radiation source will minimise the amount of radiation you receive. Summary • At the Australian Synchrotron you will not be exposed to any significant levels of radiation. • Signs, barriers and warning lights are used to advise where radiation is present and to help control access to areas. • SHIELDING, DISTANCE & TIME will minimise the amount of radiation you will receive. • Our aim is to ensure that all radiation doses are as low as reasonably achievable (ALARA principle). • The risk from a low level of radiation exposure is no different to other risks faced everyday.