Adhesives and Sealants

advertisement

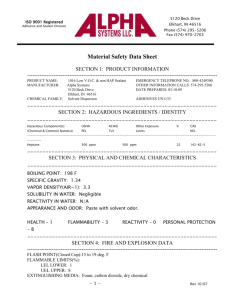

Adhesives and Sealants As Builders we need to know or be able to locate technical information about these products. Adhesives The best place to find information about these products is a manufacturers website. Try this Google search Choose a manufacturer that you recognise Adhesives work by linking to materials and then solidifying Due toSolvent loss (including water) Chemical reaction. Cooling of a pre-heated adhesive. Other names for adhesives Glue Cement Solvent / cement: (used to weld plastics rather than glue) BRANZ bulletin 356 suggests:“The commonest cause of bond failure is failure to follow adhesive manufacturers instructions.” Storage or shelf life, length of time an adhesive can be stored. Pot life, after mixing time adhesives remain suitable for use. Mixing time, adhesives (like casein or aerolite) require reaction time after mixing before it can used. Assembly time, time between adhesive application and the application of pressure. Curing time, time taken to attain sufficient strength. Catalyst/hardener, a substance which initiates adhesive to set. Gap-filling, usually in the form of a powdered extender which is added to liquid adhesive. Allows adhesive to bridge wider glue line gaps (up to 1.3 mm) without affecting the strength. Thermoplastic, adhesive softens with heat. Thermosetting, adhesive hardens with heat. Elastomer, adhesive with elastic or rubber-like properties. Often marketed as adhesive / sealant. Adhesives are often grouped into three types Structural adhesives Construction adhesives Woodworking adhesives STRUCTURAL ADHESIVES Are high strength adhesives used in laminated beams, structural plywood or boat building. CONSTRUCTION ADHESIVES Are cartridge grade adhesives that are normally used in conjunction with fasteners for low stress applications i.e. panel bonding. The adhesive is cured by the evaporation of either water or solvent. WOODWORKING ADHESIVES Different types of Poly Vinyl Acetates (PVA) and aliphatic resin adhesives dominate the building-site woodwork glues. PVA is a white coloured, and aliphatic, a cream coloured liquid. . Contact Adhesives Two types of contact adhesive are available Adoa F2 and Thixotropic Ados F2 These glues are strong smelling and are used to bond ,rubber, plastics, timber,laminates,plastic,cork and weatherseals . Sealants Sealants are a non-rigid (elastomeric) type material, used to waterproof joints or seal joints to prevent air movement between various building components Sealants elastomeric nature, allows the sealant to expand or contract within the joints. Sealants are generally marketed as “gunable” thick pastes and packaged in cartridges or socks. Compatibility of sealant with substrate is important (e.g. sealants with an acidic cure may not be used to seal joints in concrete products) Bathroom and wet area sealants often contain anti-mould inhibitors. Common applications Seals between pre-cast concrete units ( to weatherproof or stop air movement) Peripheral seals to weatherproof around aluminium joinery. Joints to external cladding and sheathing. Expansion and contraction joints (high differentials of thermal expansion) Waterproofing and sealing in wet areas (bathrooms and showers etc.) Glazing Sealing around pipes (through timber framing, concrete construction) Sealing joints in air conditioning ductwork. Flexible joints (between concrete floors and machinery) As a flexible and waterproof pointing between ceramic, earthenware tiles and stone work (often granite or marble panels) The selection of a sealant depends on: Compatibility of sealant with the substrate (will substrate need priming) Width of joint. Movement capability of the sealant (expressed as percentage movement of joint width) Interior or exterior application, amount of movement, heat, and chemicals. Ease of installation, tooling off and cleanup (two and three pot sealants are messy and have limited pot life) Toxic risks Cost TYPES OF SEALANTS Oleoresinous sealant Butyl rubber sealant Acrylic sealant Polyurethane sealant TYPES OF SEALANTS Oleoresinous sealant (Secomastic) Called mastic. Seals by remaining putty like (basically linseed oil and whiting with different oils and fillers to maximise retention of fluids). Accommodate about 5% joint movement. Maximum 5 year life . Butyl rubber sealant (Stormseal, Seelastrip) ( turns into a rubber-like compound) Performance is superior to mastic. Uses are limited to bedding in applications and pointing of glazing. Accommodate limited movement Maximum10 year life. Acrylic sealant (No More Gaps, Gaps ‘n’ Cracks) Fill gaps prior to painting with non-enamel paints Seals joints in acoustically designed areas. Accommodate +/- 5% joint movement Designed for interior use. Polyurethane sealant (Uraflex) May be formulated as one or two part sealant. Good flexibility - 25% joint movement. Durability of up to 15 years. Used as a joint sealer (depending on the type selected) Polysulphide sealant (Thioflex 600) Manufactured as one, two or three pot (different formulations to address sag resistance, width of joint, on-site conditions etc.) A tough, rubber like sealer with excellent adhesion and 25% joint movement. Used extensively in the construction industry for sealing horizontal and vertical joints (5 to 50mm wide) between pre-cast and tilt-slab components, and fibre cement sheets. Joint surfaces require priming. Durability in excess of 20 years. Silicone sealants Acetic acid cure sealant. (Silaflex RTV) Used extensively for glazing applications, expansion and waterproof joints in ceramic tiling and stainless steel joints. Used in bathroom and kitchen areas (mould inhibitor required) Withstand long term immersion in water (but not permanent) Not suitable for concrete, fibre cement sheets, galvanised steel or specified plastic or acrylics. Joint movement 10% Maximum 25 year life. Neutral Cure (Silaflex B, Silaflex N, Silaflex NG) Very good adhesion only if used with the right substrate Use Silaflex B for timber, concrete brick and fibre cement sheeting Use Silaflex N for coated and uncoated metals (plumbing & roofing) Use Silaflex NG for glass, ceramic and plastics Movements up to +/- 10% Maximum 25 year life Modified Silicones (also neutral cure) (Silaflex MS) Excellent primerless adhesion to all the substrates mentioned above and particularly powder coated aluminium. Paintable and won’t stain natural stone. High movement accommodation up to +/- 25% Maximum 25 year life -. Note: Best option for a multi-purpose sealant Epoxy urethane (Nitoseal 280) A three part, heavy duty sealant used for sealing internal factory floor joints. Movement capability of up to 10%. Epoxy (Nitoseal 281) A joint sealing compound for low movement and hard wearing floor joints. Bitumen synthetic rubber (Plastiseal) A flexible gun applied sealant suitable for sealing limited movement joints in retaining walls, basements and the like. Bitumen based is not compatible with other sealants, however it may be used with bituminous tanking i.e. Mulseal. JOINT DESIGN Joint Design should aim to: Reduce the exposure of the sealant to the weather Minimise the damage to the building should the joint fail Provide good access for joint repair or maintenance Get a width to depth ratio of 2:1 with a minimum depth of 6mm. Some joints may require a 1:1 ratio. Provide a bond breaker at the back of the joint so the sealant adheres to the sides. If the joint fails the bond breaker will be a backup seal. Have clean straight edges at the joints. Bitumen synthetic rubber (Plastiseal) A flexible gun applied sealant suitable for sealing limited movement joints in retaining walls, basements and the like. Bitumen based is not compatible with other sealants, however it may be used with bituminous tanking i.e. Mulseal. E HEALTH PRECAUTIONS Adhesives and sealants contain hazardous chemicals i.e. formaldehyde and methyl-butyl ketone. Health risks are caused by: inhalation of the fumes contact with the skin swallowing To avoid health risks: Read manufactures hazard warnings Use gloves. (Disposable gloves are cheap and easy to use) Wear eye protection if necessary. Working area is well ventilated. Wear a suitable mask if the fumes are likely to be a hazard.