Critical Design Review

advertisement

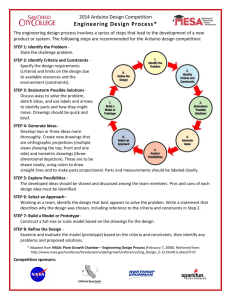

Critical Design Review The Fab Four Jeremy Conrad Electronics Expert Javier Matamoros Thrust Guru “Airship… Greg Wood Working Specialist Luis Williams Perez Computer Technician Critical Design Review The Fab Four Jeremy Conrad Electronics Expert Javier Matamoros Thrust Guru “Airship… of Doom!” Greg Wood Working Specialist Luis Williams Perez Computer Technician Outline I. II. III. IV. V. VI. VII. VIII. IX. Mission Final Design Introduction Scale Drawings General Structure Materials Weight Analysis Control Systems Other Adjustments Conclusion Fab 4 World Domination Plans To Crush All Who Oppose Us The Fab 4 Mission Through the use of knowledge acquired during the semester and extensive testing of our various options to produce a final product. This final product should be of a caliber that will meet our design requirements, and allow us to participate competitively in the race. Final Design Introduction We arrived at our final design after careful consideration of other options. The other designs were eliminated after consideration of weight, drag, number of motors, and ability to steer. Four and two balloon designs, as well as the 2 other designs presented at PDR were eliminated because they were not as competitive. Scale Drawings (side view) Scale Drawings (top view) Scale Drawings (front view) General Structure As previously presented, we chose a “net” design. We have a basic frame around the balloons, which will be supported by the netting. In this configuration, most of the load is taken by the balloons and nets. General Structure Nets have been replaced by lightweight, strong fabric paper. Holes will be cut in the paper in non-crucial spots to further reduce weight while keeping necessary strength. Materials Main structure: Balsa wood Standard Elmer’s wood glue Fabric paper “netting” Balloons Electronics package Weight Analysis Balsa: Motors (2): Props (2): Servos (2): Receiver : Receiver Bat: Netting: Batteries +wire: 170 g 420 g 10 g 86 g 27 g 94 g 80 g 235 g Total: 1.122 kg Control Systems (Yaw) Yaw control will be achieved through differential thrust. The two large motors are placed on the long crossbar to enable a turning moment. Control Systems (Pitch) The original design involved a rotating crossbar manipulated by a single servo. We decided this would be difficult to implement, and might require much additional weight. Our final design involves a servo attached to each motor, both on a single control channel. Control Systems (Roll) Roll instability was a concern during PDR. This issue was resolved by lowering the center of weight by hanging the electronics package and additional payload under the balsa frame with wires. Other Design Adjustments Joints between lengthwise and crosswise members originally had a very small contact patch. Small pieces of balsa were attached to the sides of contact patches to increase contact area and joint strength. Motors will be attached to the servos, instead of directly to the crossbars to provide pitch control Conclusion Though there remains some testing to be done, and some minor issues to resolve, there are no major problems which stand between us and a final product. We see no obstacles between us and a smooth finish.