SAPFacilityDesign_2013 - Industrial Engineering 2011

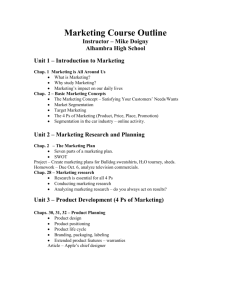

advertisement

__________________________________________________________________________________ Faculty : Engineering Program : Industrial Engineering Unit : Facility Design Code : IEN10243 Credits : 3 credits Semester : 1 Prerequisite : - Lecturer : Anastasia Lidya Maukar Period : 12th September - 10th December 2013 Content This course is a study of principles and methods for analyzing and designing plant facilities and location. Selected topics include traditional facility layout planning methods, systematic and computerized layout planning, warehouse design, materials handling and facility location. Objectives Upon completion of this course, the student will: 1. Understand the facility layout design process. 2. Be able to prepare a facilities layout for the efficient flow of materials through a facility. 3. Be able to calculate the number of machines required to meet a desired production capacity. 4. Be able to prepare a from-to chart to measure and analyze quantitative flow requirements. 5. Be able to prepare a Relationship chart to analyze qualitative relationships between departments. 6. Be able to determine space requirements for equipment, materials, and people. 7. Know the basic algorithms and computerized techniques for facilities layout 8. Be able to determine the facility location using facility location models. 9. Be able to prepare a written technical report and deliver a template. Learning Activities/Classroom Policy Students are required to be in class and to actively participate in class instructions. Students will complete a project, quizzes, and a final evaluation. 1 Assessments* Assignments Week due Percentage Projects Week #3, 5, 11 35% Quiz Week # 3, 5, 10, 12 15% Mid-term Examination Week # 7 25% Final-Term Examination Week # 13 25% Total 100% Grading Policy A - 85-100 B - 70-84 C - 60-69 D - 55-59 E - <55 References** Tompkins, J.A., et al., Facilities Planning, 3rd ed, John Wiley & Sons, 2003. Heragu, Sunderesh, S., Facilities Design, CRC Press, 2008. Meyers, Fred, E., Stephens, M.P.”Manufacturing Facilities Design and Material Handling, 3rd ed, Prentice Hall Inc., 2000. Meyers, Fred, E., Plant Layout and Material Handling, Prentice Hall, 1999 Sule, D.R., Manufacturing Facilities: Location, Planning, and Design, 3rd ed, CRC Press, 2009. Apple, James M.., Plant Layout and Material Handling, 3rd ed, John Wiley & Sons, 1983. (Reprint 1999) Project A term project will be assigned that will require students to use the material being taught in the course. The project should be performed in a group of 4 students. The project will be given and should be submitted as a weekly assignment. The team will make periodic written report. At the end of the class, the team will make an oral presentation of their result. A written final report will also be submitted at the time of the presentation. Project Schedules Week Assignment 1 Product and Process Analysis 3 Machine Requirement 5 Space Requirement Description Photograph, Bill of Material, Parts and Material Specification, Operation Process Chart and Assembly Chart, Machine Specification and Dimension. Routing Sheet, MPPC, Determination of number of machine and operators, organization structure and determination of the number of personnel Space requirement for: office, production floor, Submitted in Week 3 Week 3 Week 6 2 6 8 10 storage, warehouse, and other supporting facilities (parking, toilet, canteen, etc) Quantitative Data Analysis and From-to Chart Week 10 Qualitative Data Analysis ARC ARD (activity relationship diagram for office and the plant) Layout Design and Material Handling Layout Design using the algorithm. Week 12 Material Handling Cost Template and Written Final Report Week 13 MATRIX Week 1 Topics/ Brief Content Introduction to the Course Introduction to Facility Planning Objectives Assignments and Assessments Source** In this unit, the students will : - Understand the significance of facility planning - Understand different type of facility layout problems. Heragu (2008) chap. 1., Meyers(2000) chap1, Tompkins(2003) chap 1 Heragu(2008) chap. 2, Meyers(2000) chap 2 & 4, Tompkins(2003) chap 2 2 Product, Process, and Equipment Design and Analysis In this unit, the students will - define and analyze product, process and schedule design interactions by studying the functions involved in the product development cycle. 3 Traditional Approaches to Facility Layout: Systematics Layout Planning (SLP) In this unit, the students will: - Understand the step how to design facilities layout using traditional method , especially SLP 4 Flow, Space, and Activity Relationships In this unit, the students will: - Understand the material flow - Be able to define the activity relationship by material flow or personnel flow, environmental considerations, organizational structure, and other considerations. Meyers(2000) chap 6-8, Tompkins(2003) chap 3-4 5 Flow, Space, and Activity Relationships (continued) Personnel Requirements In this unit, the students will: - Be able to calculate labor and machine requirements for a manufacturing facility, by Meyers(2000) chap 6-8, Tompkins(2003) chap 3-4 Quiz #1 Heragu(2008) chap. 3-4, Meyers(2000) chap 5, Tompkins(2003) chap 3 3 discussing the make-buy issues, man-machine charts and capacity requirement methods. - Be able to calculate and plan personnel requirements include planning for employee parking, locker rooms, rest room and other supporting facilities. 6 Group Technology 7 In this unit, the students will: - Be able to design the group technology layout using clustering approach Heragu(2008) chap. 6 MID TERM TEST 8 Basic Algorithm for Facility Layout In this unit, the students will: - solve facility design problems through analyzing layout models and design basic algorithms theoretically using MST and GTA Heragu(2008) chap. 5, Tompkins (2003) chap.6 9 Computerized Layout Planning: CORELAP, ALDEP In this unit, the students will: - Understand the step how to design facilities layout using computerized layout planning for qualitative approach Heragu(2008) chap. 5, Tompkins (2003) chap.6 10 Computerized Layout Planning: CRAFT In this unit, the students will: - Understand the step how to design facilities layout using computerized layout planning for quantitative approach Heragu(2008) chap. 5, Tompkins (2003) chap.6 11 Material Handling In this unit, the students will: - Understand, design and analyze material handling systems through different material handling equipment and material handling principles used in the warehousing, manufacturing 12 Warehouse Operation In this unit, the students will: - Understand the Quiz# 2 Tompkins (2003) chap.5 Tompkins (2003) chap.7 4 warehouse function and storage operation - Be able to design a warehouse 13 14 Facility Location In this unit, the students will: - understand the basic model of facility location - be able to determine the best location based on quantitative and qualitative factors - solve facility location problems by applying analytical facilities location method Heragu(2008) chap. 11-12, Tompkins(2003) chap. 10, Sule (2009) chap. 17-19 FINAL TERM EXAMINATON 5