CHE 481-483: Process Design Final Design Project Presentation

advertisement

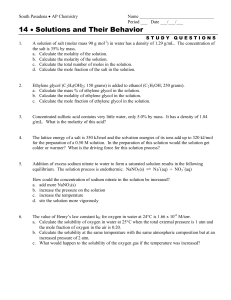

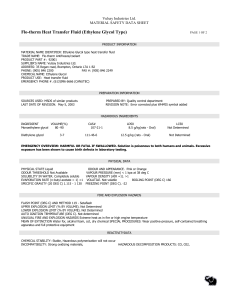

CHE 481-483: Process Design Final Design Project Presentation Chemical & Biological Engineering Department Drexel University Manufacture of Ethylene Glycol Design Team: Name Topics Covered in Presentation Chong McLaren Project Scope Nicholas Mitchell Process Description Timre Segear Economic Feasibility Suroor Manzoor Safety & Environment Conclusions & Recommendations Academic Advisor: Dr. George Rowell Industrial Advisor: Mr. Steven Schon, P.E. Project Scope Chong McLaren Size of Plant Ethylene Glycol Diethylene Glycol (By-product) 896 MM lbs/Yr 99.8% Purity (Polyester Fiber Grade) 2.2 MM lbs/Yr 99.6% Purity Raw Material Ethylene: 484 MM lbs/Yr Oxygen: 370 MM lbs/Yr at 99% Purity Location Port Arthur, TX BASF/ATOFINA steam cracker Grass-Roots Site Self Sufficient Unit (Utilities & WWTP) Production of EO Technology EO Reactor Shell Technology vs. Chlorohydrin process Silver Catalyst Efficient & Environmentally friendly No unwanted byproduct Ethylene Conversion: 12.5% Oxygen vs. Air Reduce quantities of inert gases into recycle Eliminate the need for a purge reactor system Higher selectivity: 65-75% vs. 85-90% Higher operating cost Higher risk of handling Production of EG Technology EG Reactor Ion Exchange Catalyst vs. No Catalyst Hydrolysis of EO Reduce operating temperature by 150 °F Reduce amount of excess water Water:EO - 20:1 to 4:1 EO Conversion: 98% Higher MEG selectivity: 91% vs. 98% Chemistry Ethylene Reaction: C2H4 +1/2 O2 → C2H4O Side Reactions: C2H4 + 3 O2 → 2 CO2 + 2 H2O C2H4O + 2 1/2 O2 → 2 CO2 + 2 H2O EO Reaction: C2H4O + H2O → C2H6O2 C2H4O + C2H6O2 → C4H10O3 Market Analysis EG Worldwide Production GLYDE: 896 MM lbs/Yr of EG Production 31.2 Billion lbs/Yr 20% in US 3% of World market 14% of US market Growth Rate 6%-7% globally per year between 2006 - 2010 Market Analysis Polyester Grade EG Demand for Derivatives Uses Demand of EG ↑, Demand in End-Use Segments ↑ automobile coolant, antifreeze additive, fiber, film, PET bottles, solvent in printing ink PET Film 3.6% Other 3.0% Industrial 5.4% Antifreeze 11.4% PET Bottles 24.5% Polyester Fiber 52.1% Process Description Nick Mitchell Ethylene Section 200: 300: 400: 500: 100: Block Flow Diagram EG EO CO EGPurification EO Absorption Removal Section Section Section Section 2 Reaction Feed Prep Purge Flare CO2 Absorber Oxygen OMS EO Reactor CO2 EO Absorber CO2 Stripper EO Stripper • EG Ethylene Carbon Reactor Dehydration Dioxide OxidePrep Feed Absorber Absorber • Oxygen Ethylene Carbon EG Purification Dioxide Mixing Oxide Station Stripper Stripper • Ethylene Oxide Reactor EG Reactor EG Dehydration EG Purification EG DEG Section 100: EO Reaction Feed Prep Turbine Ethylene Pipeline Reactor & Cooler 150 MM Btu/hr to Oil Recycle Compressor System 55,000 lb/hr Recycle Compressor •8,600 Trim cfmCooler •2,900 HP •2 Stages Recycle 412, 000 lb/hr EO Reactor oCO2 Section Tin ( F) 300 Oxygen Mixing Station EO Reactor •Safe Mixing of Oxygen •Avoiding Flammability Range Tout (oF) 570 Operating Pressure (psig) 210 Type Shell & Tube Oxygen Catalyst Silver Based Tube Length 20 46, 000(ft)lb/hr Tube Diameter (in.) 1.25 Station Oxygen Mixing Number of Tubes 14,000 2 Area (ft ) 91,000 Hot Oil Coolant Pre-Heater Section 200: EO Absorption Pre-Heater Cooler Trim Cooler EO Stripper D = 10 ft Trim Gas 20 Trays Cooler Cooler Feed @ 10 Required EO/Water Liquid Concentration 10.9 4.3 10.4 EO Trim Cooler Stripper Gas Cooler EO Absorber Liquid Cooler To Purge, Recycle, & CO2 Removal EO Absorber D = 10 ft Heat Duty 10 37 51 108 (MM Btu/hr) Structured Packing Number of 3 1 Reactor 5 HETP = 124 in. EO Shells Area (ft2) Packing 13H = 32.7 40 ft 4.3 52 *1000 Hot Oil Coolant Area Per Shell 13 (ft2) (*1000) EO Rich Feed Pre-Heater Stripper PreHeater Water Recycle Section 300: CO2 Removal Absorber Vapor To Purge, Recycle, & CO2 Removal Make Up Water EO Absorber Purge to Flare CO2 Stripper Gas D = 4 ft Trim Cooler Cooler 15 Trays Ethylene Feed @ 1 Liquid Cooler Stripper PreHeater Recycle to EO Reactor Section EO CO Stripper 2 Absorber CO2 Absorber CO2 to Flare CO to 2 D = 4 ft Flare Structured Packing HETP = 24 in. Packing H = 40 ft CO2 Stripper CO2 Stripper Section 400: EG Reaction Lights to To Purge, Recycle, & CO2 Removal Compressor EO Absorber EG Reactor EO Tin (oF) Stripper Tout (oF) PreCooler Trim Cooler Gas Cooler EO/Water Solution Liquid Cooler Operating Pressure (psig) Type Catalyst Flash Tube Length (ft) Tube Diameter (in.) Number of Tubes Area (ft2) EG Solution Trim Cooler Stripper PreHeater EG Reactor 195 Stripper Distillate 195 120 Shell & Tube Ion Exchange 20 1.25 1,200 7,900 Section 500: EG Purification Lights to Lights to Compressor Compressor EG Dehydrator EG Product EG Product 110,000 lb/hr 110,000 lb/hr – D = 10.5 ft 99.9 wt% 99.9 wt% Flash – D = 14 ft – 38 Trays – 35 Trays – Feed @ 15 DEG ProductDEG Product 265 lb/hr 265 lb/hr – Feed @ 14 wt% 99.9of wt%.1 99.9 – Max Water wt% EG Solution – Side Stream @ 26 PreEG Purification Cooler EO/Water Solution EG Trim Cooler Dehydrator EG Reactor Water to EO Absorber DEG/TEG DEG/TEG 25 lb/hr 25 lb/hr EG EG PurificationPurification Key Process Assumptions Overall Heat Transfer Coefficients 150 Btu/hr sqft oF 50 Btu/hr sqft oF Elsewhere Boiling or Condensing Liquid/Liquid Gas/Liquid Gas/Gas EO Reactor Pressure Drop 15 psi in Packed Bed Reactors 6 psi in Heat Exchangers < 3 psi in Vacuum Heat Exchangers Pressure Drop in Columns Estimated by Aspen Key Process Assumptions Purity of Raw Materials Ambient Temperature & Humidity Wet Bulb Temperature for Cooling Water Operating Time 8,100 hrs/yr (~4 wks downtime) Key Process Assumptions EO Reaction Kinetics EG Reaction Kinetics Shell Catalyst is Proprietary Conversion & Selectivity Ion Exchange Resin only used in Lab Scale Pilot Plant Required to test BOTH Catalysts Economic Feasibility Timre Segear Economic Assumptions Sales: Ethylene Glycol Selling Price: 2008 224 MM lbs 2009 672 MM lbs 2010 & on 896 MM lbs 2008 38 c/lb (2 years contract) 2009 38 c/lb (2 years contract) 2010 & on 39 c/lb (then inc. 2%/yr) Variable Cost : 18 c/lb (2010 $, inflate @ 2% /yr) Fixed Cost: 3.6 c/lb (2010 $, inflate @ 2% /yr) Administration & Sales: 3 % of sales R&D: 3 % of sales Economic Assumptions Total Fixed Capital: 175 $MM ISBL + OSBL (50% of ISBL) 131 $MM in 2007 75 % of Fixed Capital in 2007 43 $MM in 2008 25 % of Fixed Capital in 2008 15 $MM in 2007 12 % of Fixed Capital in 2007 7 $MM in 2008 6 % of Fixed Capital in 2008 5 $MM in 2009 4 % of Fixed Capital in 2009 Start - Up: Federal and State Taxes: 39% Working Capital: 18 % of sales Depreciation: 16 $MM/yr (Straight Line Depreciation over 11) Fixed Costs Labor (w/ Overhead) Operating - Board - Field Supervisor Basis $M/Shift # Shifts Total Cost ($M/yr) Total Cost (c/lb) 2 Operators/shift 1 Operators/shift 2 Operators/shift 300 125 400 3 3 3 900 375 1200 0.10 0.04 0.13 Total Cost (c/lb) Basis $/hr Total Hrs/yr Total Cost ($M/yr) 2 Mechanical 1 Instrumentational 40 40 3840 1920 1200 600 0.13 0.07 2 Technicians 50 8100 800 0.09 Total Cost ($M/yr) Total Cost (c/lb) 460 460 460 460 0.05 0.05 0.05 0.05 6915 0.77 Maintenance Quality Control Engineer Total Labor Cost Basis 1 per major unit(s) 1 EO System 1 CO2 System 1 EG System 1 OSBL Fixed Costs Supplies Basis Total Cost ($M/yr) Operating Supplies Maintenance Supplies 10% Operating Labor 60% Maintenance Labor 127.5 1080 0.01 0.12 Total Supplies 1207.5 0.13 Indirect Costs Basis Total Cost ($M/yr) Total Cost (c/lb) Depreciation Taxes & Insurance 11 yr. straight line 2% of Fixed Capital 15907 2 1.78 0.00 15909 1.78 Total Indirect Costs Total Fixed Costs ($M/yr) 24032 Total Cost (c/lb) 2.68 Total Cost (c/lb) Other Capital Costs Assumptions Five miles of piping uninstalled cost $1MM Cost factor of 5 for a total of $5 MM Oxygen Mixing Station uninstalled cost of $1 MM Cost factor of 4.44 for a total of $4.4 MM Seader, Seider and Lewin 600 MM lbs/yr in 1995 $80 MM 896 MM lbs/yr in 2006 $123 MM Reassuring our capital cost ($175 MM) is reasonable Cost vs Revenue 40 Total = 38 c/lb 35 Supplies Cents/lb Product 30 25 20 Total = 23.3 c/lb Capital Cost Indirect Utilities Labor Product 15 10 Raw Material 5 0 Cost Revenue Ethylene Price Sensitivity Ethylene Glycol - 896 MMlb/yr 25% Design Design CaseCase = 19% 19% 20% IRR % 15% 10% Hurdle Rate 12% 5% 0% 0.28 0.33 0.38 Ethylene Price (c/lb) 0.43 0.48 Capital Cost Cost Sensitivity Capital Sensitivity Ethylene Glycol - 896 MMlb/yr Capital Cost – 175 $MM 35% 30% Design Case 25% 19% Design Case = 19% IRR % 20% 15% 10% Hurdle Rate 12% 5% 0% 50% 60% 70% 80% 90% 100% +/- 50% Capital Cost 110% 120% 130% 140% 150% Reaction Selectivity 100 Design Case After Tax Cash Flow (MM $ / yr) 90 88% EO 80 100% EG 98% EG 95% EG 70 90% EG 60 50 40 30 20 Increasing EG Selectivity Increasing EO Selectivity 10 0 84% 86% 88% 90% 92% 94% EO Reaction Selectivity 96% 98% 100% Price/Capacity Sensitivity Ethylene Glycol - 896 MMlb/yr 40% Current Market Price 35% 1000 MM lb/yr 30% 896 MM lb/yr DCF IRR, % 25% Design Case 19% 20% 600 MM lb/yr 15% 10% Hurdle Rate 12% 5% 0% $0.30 $0.35 $0.40 Price (2006) $0.38, $/lb $0.45 $0.50 After Tax Cash Flow Diagram 200 150 100 $MM 50 0 1 2 3 4 5 6 7 8 9 -50 -100 -150 -200 Year 10 11 12 13 14 15 16 Cumulative Cash Flow Diagram 1400 1200 1000 $MM 800 600 400 200 0 1 2 3 4 5 6 7 8 9 -200 Year 10 11 12 13 14 15 16 Economic Conclusions Total Capital Costs $175 MM Raw Materials is major manufacturing cost Anticipated Internal Rate of Return: 19% Hurdle rate: 12% Break even period: 3 years Preliminary results lead us to believe this is an economically feasible process Safety & Environment Conclusions & Recommendations Suroor Manzoor Safety Safety Concerns Ethylene Oxygen mixing station Highly Explosive and Hazardous Potential Source of Explosion Located in Bunker Ethylene Oxide Very Toxic Human Carcinogen Safety Risk Management Utilities Consideration Fire Prevention Shut off Oxygen & Ethylene Supply Back up generator Shut Down Fire Suppression System Shut off all gas streams Wrong Feed Ratios Safety Risk Management Leaks and Spills Process Waste Ventilate Area Isolate Area Spill Collected or Absorbed Flare Recycle and Blending Plant Layout MAIN ROAD PREVAILING WIND MAIN GATE C-501 C-101 E-101 E-401 E-402A MACHINE SHOP PARKING SHIPPING & RECEIVING V-401 R-101 E-402B E-103 E-501A T-501 E-501B V-501 PIPE RACK MAINTENANCE BLDG ROAD WAREHOUSE E-102 R-401 T-201 E-201 E-204C E-202B E-501C E-204D E-202C E-502A LAB P-501 P-201 E-204A P-503 V-502 T-502 E-503 P-502 P-504 P-505 P-506 TK-103 E-601 TK-104 P-203B P-301A P-601 P-301B P-602 P-303 ETHYLENE PREP E-206 P-203A V-601 TK-105 E-205 P-202B T-301 TK-102 TK-101 V-202 P-202A OXYGEN PLANT E-301 N2 TANKS LOADING STATIONS GATE ROAD RAILROAD SIDING UTILITIES WASTE WATER PLANT O2 MIXING STATION 50 ft FLARE ROAD E-504 V-201 T-202 PIPE RACK CONTROL E-204E E-203 E-502B OFFICE E-204B E-202A Environmental All raw materials/products biodegradable DEG byproduct Sold Waste Management Streams recycled to optimize process No process waste water WWTP Bottoms from EG Purification blended into MEG product stream Emissions Issues Economics Ethylene price Technical 1c/lb is a difference of $9 million/yr Reaction kinetics of silver catalyst proprietary Glycol resin catalyst only tested on lab-scale Product Purity of Ethylene Glycol The final price drops by 25% if purity is in the range 98-99.8% Conclusions Capital investment: $175 million Production rate: 896 million lb/year EG Anticipated Internal Rate of Return: 19% Break even period: 3 years Hurdle rate: 12% Economically Feasible Process Recommendations Lock Ethylene price Process Optimization Heating, Cooling CO2 Catalyst Acknowledgements Dr. George Rowell Mr. Steve Schon, P.E. Dr. Richard Cairncross Dr. Elihu Grossmann Questions Nick Timre vs Chong Suroor