Advanced Planning Systems

advertisement

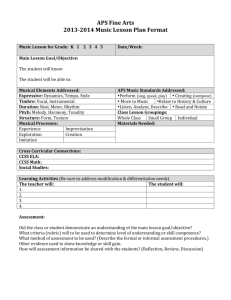

Advanced Planning & Scheduling (APS) Presentation to Semtech By David Malmberg Topics for Discussion Advanced Planning & Scheduling (APS) – a Definition Evolution of APS Technology APS Capabilities “Umbrella” Planning vs. Execution Systems Issues to Consider before Selecting and Implementing an APS Leading APS Solution Providers June 6, 2002 2 APS – a Definition Software which assists in managing the match between customer demand and product supply APS features/functions vary greatly among software solution suppliers APS is typically “bolted-on” to ERP and/or other legacy systems Benefits include: 3 Faster cycle times Reduced inventory Improved delivery performance Increased profitability Typical APS Benefits 4 Faster cycle/throughput times (e.g., 25-50%) Reduced inventory (e.g., 25-50% WIP reduction) Improved delivery performance (e.g., “perfect order” delivery improvements as high as 90%) Increased profitability (e.g., significant volume and margin gains) Specific Examples of Benefits 5 Gullistan Carpet cuts its inventory by more than 30% A magazine publisher reduced its returns (unsold magazines by 40%) while reducing its out-of-stocks by 30% Rexam Packaging cuts its average manufacturing cycle time by 50% Avex Electronics reduced WIP by 50% and doubled its total inventory turns CNT realized 59,000 man-hours of productivity improvement which represented a $2.9 million savings during the first 12 months after implementation SalesLink experienced a “significant reduction in inventory while virtually eliminating material shortages” Titlest reduced its manufacturing throughput time from 12 days to less than 5 enabling it to offer 2-day guaranteed service to its customers Manufacturing Planning Activities Procurement Production Distribution Long -term Materials programs Supplier selection Vendor Management Plant location Production system Physical Distribution Structure Mid -term Materials Planning Contracts Master Production Scheduling Capacity Planning Short -term 6 Ordering Materials Machine Scheduling Lot-Sizing Shop Floor Control Distribution Planning Warehouse Replenishment Transportation Planning Sales Product Program Strategic Sales Planning Mid-term Forecasting & Sales Planning Short-term Forecasting & Sales Planning Manufacturing Software Modules Procurement Long -term 7 Distribution Sales Strategic Network Planning Mid -term Short -term Production Master Planning Material Requirements Planning (MRP or ERP) Production Planning Scheduling Distribution Planning Transportation Planning Forecasting & Demand Planning Demand Fulfillment & ATP Manufacturing Software Modules Procurement Long -term Distribution Master Planning Material Requirements Planning (MRP or ERP) Production Planning Scheduling Distribution Planning Transportation Planning Typical APS Modules/Functions 8 Sales Strategic Network Planning Mid -term Short -term Production Forecasting & Demand Planning Demand Fulfillment & ATP Key Differences between ERP and APS ERP 9 Little planning or decision support capability Planning cycle is typically weekly or longer No capacity constraints Fixed lead-times are input to process No modeling Generates “feasible” production schedule Focuses on forecasts Normally - make-to-stock No easy way to determine ATP, CTP and/or PTP APS Rich in planning and decision support capability Planning cycle is typically minutes Capacity constraints Variable lead-times are output from process Modeling/simulation Generates “optimal” production schedule Focuses on actual demand Normally - make-to-order ATP, CTP and PTP Evolution of APS Technology What do I need? Can I make it? Consider material and/or manufacturing constraints (i.e., more accurate plans) Concurrent materials and resource planning and scheduling Can I make and distribute it? 10 Forecasting and MRP Consider distribution constraints (replaces DRP) Concurrent manufacturing and distribution planning/scheduling Evolution of APS Technology What should I make? What should the whole supply chain make and sell? 11 Full planning/scheduling suites (including webbased) Synchronized plans (across functions) Availability, Capability and Profitability-to-Promise Alerts and exception management Joint planning among trading partners Full instantaneous supply chain information sharing Synchronized inter-enterprise operations APS Capabilities “Umbrella” 12 Supply Chain network design Demand planning/forecasting Sales and operational planning Inventory planning Ability-to-promise (Should we take the order?) Distribution and transportation planning Production scheduling Shipment scheduling Constrained simulation and/or optimization Alerts and exception management Inter-company collaboration and CPFR Planning vs. Execution Systems Planning Level Supply Chain Visibility Order Management Warehouse Management Operational Supply Chain Execution Transportation Mgmt Intl Trade Logistics Supply Chain Planning Inventory Management Production Scheduling Manufacturing Planning Distribution Planning Tactical Supply Planning Supply Chain Collaboration Demand Forecasting & Planning Supply Chain Network Design Strategic Seconds/ Minutes Hours/ Days Weeks/ Months Quarters Years Time Horizon Source: AMR Research 13 Issues to Consider before Selecting and Implementing an APS What specific problems are you trying to solve? Which APS solution supplier is best for you? 14 Is an ASP the best solution? What APS capabilities under the “umbrella” are most important? How important are these issues/problems to your customers? Are you willing to commit the resources required for a successful implementation? Best fit with your and your customers’ needs Features and functionality appropriate for your company and your industry Compatibility with legacy systems and future system plans Track record of implementation success and on-going support Leading APS Solution Providers Adexa Aroon Blinco CAPS Catalyst Demand Management Dementa GLog i2 IMI Intentia JDA J. D. Edwards Logility Manugistics MARC Source: Gartner Group and CGR, 2002 15 McHugh Mercia Peoplesoft Planalytics Prescient QAD QRS SAP SCT Smart/Ops Swisslog Syncra Synquest Tecsys Veratile Vertical Net