Behavior Based Safety for Supervisors

BEHAVIOR-BASED SAFETY

TRAINING FOR SUPERVISORS

CORPORATE SAFETY TRAINING

29 CFR 1910

WELCOME

BASIS FOR THIS COURSE

Statistically, safe attitudes result in accident prevention.

Safe attitudes result in safe behaviors at work.

Development of improved safe attitudes toward work.

Elimination of workplace injuries & illnesses where possible.

Reduction of workplace injuries & illnesses where possible.

OSHA Safety Standards require:

Training be conducted

Workplace Hazards be assessed

Hazards and precautions be explained

Accidents be investigated

Job Hazards be assessed and controlled

COURSE OBJECTIVES

Discuss the local safety policy.

Discuss supervisor responsibilities.

Discuss the concepts of behavior - based safety.

Introduce 29 CFR 1910, the industrial safety standards.

Discuss the OSHA penalties policy for safety violations.

Discuss methods and techniques used to protect workers.

COMPANY SAFETY POLICY

The personal safety and health of each employee of this company is of primary importance.

The prevention of occupationally-induced injuries and illnesses is of such consequence that it will be given precedence over operating productivity whenever necessary.

To the greatest degree possible, this company will provide all mechanical and physical facilities required for personal safety and health in keeping with the highest standards.

INITIAL TRAINING

THE EMPLOYER MUST PROVIDE TRAINING :

Train in Safety Related Work Practices.

Conduct Training Prior to Job Assignment.

Explain The Specific Regulations That Apply.

Teach The Local Hazard Reporting Procedures.

Explain The Hazards Associated with Their Work Area.

RETRAINING REQUIREMENTS

REQUIRED WHEN THERE IS A:

New Work Area Hazard.

Program Related Injury.

Change in Job Assignment.

New Equipment Introduced.

New Hazard Control Methods.

Failure in Written Work Procedures.

Failure in the Safety Work Practices.

Reason to Doubt Employee Proficiency.

BEHAVIORAL-BASED SAFETY

IS IMPORTANT

A GOOD PROGRAM WILL HELP:

Improve Quality.

Improve Absenteeism.

Maintain a Healthier Work Force.

Reduce Injury and Illness Rates.

Acceptance of High-Turnover Jobs.

Workers Feel Good About Their Work.

Reduce Workers’ Compensation Costs.

Elevate SAFETY to a Higher Level of Awareness.

PROGRAM IMPLEMENTATION

IMPLEMENTATION OF A BEHAVIOR- BASED

SAFETY PROGRAM REQUIRES:

DEDICATION

PERSONAL INTEREST

MANAGEMENT COMMITMENT

NOTE:

UNDERSTANDING AND SUPPORT FROM THE WORK FORCE

IS ESSENTIAL, WITHOUT IT THE PROGRAM WILL FAIL!

RESPONSIBILITY IS IMPORTANT

EFFECTIVE ASSIGNMENT OF RESPONSIBILITY

TWO WAY STREET MGMT.

SUPERVISION

LABOR FORCE

AUTHORITY & ACCOUNTABILITY

WHAT IS BEHAVIOR - BASED SAFETY?

Behavior-based safety is a safety management system that specifies exactly which behaviors are required from each employee. These behaviors are geared toward a safer work environment.

The system must have controls in place which will measure whether or not these behaviors exist as a routine element in the work environment. Acceptable behaviors must be positively reinforced frequently and immediately as the behavior occurs.

MANAGEMENT’S ROLE

Considerations:

1. Get Involved. Learn!

2. Ensure Your Support Is Visible.

3. Support the Program.

4. Implement Ways to Measure Effectiveness.

5. Attend the Same Training As Your Workers.

6. Interact With Your Workers.

7. Insist on Periodic Follow-up & Program Review.

8. Follow-up on the Actions You Took.

THE SUPERVISOR’S ROLE

Considerations:

1. Get Involved.

2. Get Your Workers Involved.

3. Never Ridicule Any Injury or Near Miss.

4. Be Positive, Motivate, and Reward.

5. Find Ways to Measure Behavior.

6. Attend the Same Training As Your Workers.

7. Be Proactive - Get Involved in Safety.

8. Be Professional - You Could Save a Life Today.

9. Follow-up on the Actions You Took.

SUPERVISOR RESPONSIBILITIES

THE SUPERVISORS PRIMARY JOB:

Control the work environment.

Enforce existing work rules.

Constantly reassess conditions.

Improve the system or process.

Involve employees.

Bring safety concerns to management.

Serve as company liaison.

SUPERVISOR RESPONSIBILITIES

Continued

Regarding Safety Training!

THE SUPERVISOR MUST:

Know the training needs of his or her workers.

Be aware of changing conditions requiring new training.

Be constantly aware of safety conditions in the workplace.

Ensure workers are included in the safety process.

Solicit ideas for safety improvements from workers.

Interact closely with the Company Safety Officer.

Halt any operation where personal injury could result.

SUPERVISOR RESPONSIBILITIES

Continued

Regarding Near Misses!

THE SUPERVISOR MUST:

Treat all “Near Misses” as an accident.

Report it.

Investigate the cause.

Determine corrective measures.

Update and annotate!

Follow up to ensure compliance.

SUPERVISOR RESPONSIBILITIES

Continued

Regarding Flow of Safety Information!

THE SUPERVISOR MUST:

Act as a conduit, upward and downward.

Act as a filter, use your experience.

Inform the sender if you change the message.

Be proactive, look for problems.

Be thorough, follow up on the actions you took.

Ask your employees to ensure comprehension.

If it doesn’t make sense to you. It won’t to your people.

SUPERVISOR RESPONSIBILITIES

Continued

ELIMINATE BEHAVIOR THAT IS DRIVEN BY:

LACK OF -

Appropriate Safety Training.

Knowledge of Personal Responsibility.

Knowledge of Safety Procedures.

Knowledge of Safety Information.

Knowledge of Machines or Equipment.

Knowledge of Facility Operations.

WHAT’S LEFT, IDEALLY IS ATTITUDINAL, WHICH DRIVES BEHAVIOR

SUPERVISOR RESPONSIBILITIES

Continued

Regarding Your Ability to Supervise!

RESPONSIBILITY ACCOUNTABILITY

SUPERVISOR

AUTHORITY DELEGATION

SUPERVISOR RESPONSIBILITIES

Continued

Regarding Your Ability to Supervise!

RESPONSIBILITY

ACCOUNTABILITY

AUTHORITY

REMOVE ANY ONE AND YOU CANNOT EFFECTIVELY SUPERVISE

SUPERVISOR RESPONSIBILITIES

Continued

Regarding Your Ability to Supervise!

RESPONSIBILITY

Safety is one of your specific duties.

You are responsible for controlling your work area.

You must be knowledgeable of your responsibilities.

AUTHORITY is needed to carry out responsibilities.

SUPERVISOR RESPONSIBILITIES

Continued

Regarding Your Ability to Supervise!

AUTHORITY

Authority is absolutely critical.

Authority must be commensurate with responsibility.

Authority allows you to take action.

Authority allows you to correct deficiencies.

Authority must be controlled.

ACCOUNTABILITY is needed to control Authority.

SUPERVISOR RESPONSIBILITIES

Continued

Regarding Your Ability to Supervise!

ACCOUNTABILITY

Accountability is the check and balance.

Accountability must be appropriate.

Accountability measures compliance.

Accountability must be used in consonance with

Responsibility and Authority.

SUPERVISOR RESPONSIBILITIES

Continued

TO VARYING DEGREES ALL

EMPLOYEES HAVE:

RESPONSIBILITIES,

AUTHORITY

AND ARE ACCOUNTABLE

FOR SAFETY.

THE EMPLOYEE’S ROLE

Considerations:

1. Get Involved.

2. Contribute to Make Corrective Actions.

3. Understand How Your Behavior Affects Job Safety.

4. Report All Accidents and Near-Misses Immediately.

5. Be Proactive and Professional.

6. Report All Safety Problems or Deficiencies.

7. Follow-up With Any Additional Information.

8. Understand the Reason Work Must be Observed.

SAFETY COMMITTEE

Safety Committees Should:

Document Meetings.

Encourage Employee Involvement.

Provide Feedback Without Fear of Reprisal.

Make Recommendations for Corrective Action.

Analyze Statistical Data Concerning Accidents.

Hold Regular Safety Review Meetings.

Bring Employee Concerns to Management's Attention.

Follow-up Is Critical.

WORKSITE ANALYSIS

WORKSITE ANALYSIS INCLUDES:

1. Gathering Behavior Information From Available Sources.

2. Observing Behavior of Employees During Varying Conditions.

3. Developing Lists of Acceptable Behavior for Specific Jobs.

4. Conducting Baseline Screening Surveys to Determine Which

Jobs Are High Risk and Need a Closer Analysis.

5. Performing Job Hazard Analyses of High Risk Jobs.

6. After Implementing Control Measures, Conducting Periodic

Surveys and Follow-up to Evaluate Changes in Behavior.

WORKSITE ANALYSIS

Continued

TANGIBLE INDICATORS:

Accident Records

Behavior Observations

Production Records

Personnel Records

Employee Surveys

Policies and Procedures

BEHAVIOR PRINCIPLES

WHAT IS BEHAVIOR?

Behavior Is What a Person Does or Says.

What

Causes a Person to Take This Particular Behavior or Course of Action Depends On Other Influencing

Factors.

Attitude and Situational Conditions

Cause The Particular Behavior.

BEHAVIOR PRINCIPLES

Continued

What Influences Behavior?

Motivation.

Intelligence.

Emotions.

Experience.

Attitude

Situational Conditions.

Desire

Need.

Abilities.

Skills.

Ambition.

What Else Can You Think Of?

BEHAVIOR PRINCIPLES

Continued

When The Reason For Behavior is Not Known.

Determine What Motivates The Behavior.

-- Lack of Training?

-- Working Conditions?

-- Personal Problems?

Work-Related Problem? - Try and Fix It.

Personal Problem? - Work Within Company Resources

Find Positive Ways To Discourage Unacceptable

Behavior.

OBSERVING BEHAVIOR

OBSERVING BEHAVIOR

Behavior Must Be Observed to

Begin to Understand Current

Behavior and Develop Lists of

Acceptable (Safe) Behaviors.

The

Lists of Acceptable Behavior Will

Be Used in Determining Safe

Behaviors in the Future.

OBSERVING BEHAVIOR

Continued

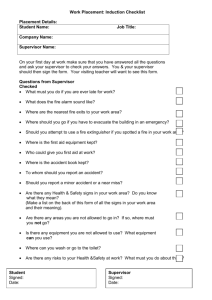

To Effectively Observe Behavior:

1. Establish Criteria For Observations.

2. Observe Workers Frequently at Various Work Times.

3. Observe Workers For a Few Minutes Each Time.

4. Employees Should Know They Are Being Observed.

5. Employees Should Know Their Behavior is Recorded.

6. Know the Safe Behaviors You Are Looking For.

7. Develop a Checklist If Necessary.

8. Constantly Compile and Compare Observations.

9. Follow-up on Observations.

OBSERVING BEHAVIOR

Continued

REMEMBER

Someone Is Always New or Young or

Unfamiliar With Why They Are Being

Observed. Determining Safe Behaviors

Is a Never-Ending Process. Your List of

Safe Behaviors Will Vary by Job or

Department and Will Change As Work

Conditions or Equipment Change.

OBSERVING BEHAVIOR

Continued

EXAMPLES OF SAFE BEHAVIORS - FORKLIFT SAFETY

• Approaches load slowly and straight-on

• Stops when forks are about a foot from load

• Safely engages pallet

• Checks mast height for obstructions

• Slowly/safely picks up load with load against backrest

• Checks rear for pedestrians, traffic, obstructions

• Stops when forks are about a foot from load

• Checks mast height for obstructions

• Safely raises forks to desired height

• Safely engages pallet and tilts to safe angle

• Slowly and safely picks up load and lowers to safe height

OBSERVING BEHAVIOR

Continued

EXAMPLES OF SAFE BEHAVIORS - FORKLIFT SAFETY

• Approaches slowly and straight-on

• Stops when forks are about a foot from load

• Checks mast height for obstructions

• Safely raises forks to desired height

• Safely drives forward until load is squarely over stack

• Safely tilts to safe angle and places load on stack

• Slowly and safely levels forks within inside of pallet

• Checks rear for pedestrians, traffic, obstructions

• Slowly and safely backs out and lowers to safe height

• Plans load route based on current path obstructions

• Carries load with load tilted back to safe angle

BEHAVIOR REINFORCEMENT

WHAT IS BEHAVIOR REINFORCEMENT?

Reinforcement Is Any Consequence That

Increases the Likelihood That the Behavior It

Follows Will Occur in the Future. In Other Words,

If You Promote a Behavior and Make Someone

Feel Good About Performing That Behavior, or

Give Them a Reason to Perform That Behavior, Its

Occurrence in the Future Will Likely Increase.

BEHAVIOR REINFORCEMENT

Continued

REINFORCEMENT

Acceptable Behavior Must Be

Constantly Reinforced.

Never Miss an Opportunity to Give a Pat on the

Back for Acceptable Behavior.

People usually Respond to Positive

Reinforcement.

BEHAVIOR REINFORCEMENT

Continued

Reinforcement Considerations:

1. Reinforce Frequently, and In Public.

2. Reinforce ONLY for Acceptable Behavior.

3. Reinforce Immediately, Never Wait.

4. Reinforce During the Safe Behavior if Possible.

5. Be Specific About the Reinforced Behavior.

6. Give Non-Verbal Positive Cues. (Nods, Smiles etc.)

7. Be Totally Positive.

8. Be Sincere. People See a Lot, But Don’t Say a Lot.

9. Accentuate The Positive.

BEHAVIOR REINFORCEMENT

Continued

Rewarding For No Accidents.

Works For a Determinant Period Only.

Once an Accident Occurs, No Incentive Remains.

Usefulness Usually Degrades Over a Period of Time.

Doesn’t Permanently Alter Unacceptable Behavior.

Diminishes Supervisory Control.

LOST TIME

ACCIDENTS

0

MOTIVATIONAL TECHNIQUES

Money and Behavior.

Is The Individual Due a Raise?

Is a Salary Review Needed For The Job?

Is The Amount of “Piecework” Pay Appropriate?

Is There a Bonus Program?

Are There Monetary Rewards for Safe Behavior?

Are There Other Incentive Rewards for Safe Behaviors?

Is There a Safety Suggestion Program?

HOW MUCH OF A MOTIVATOR IS MONEY?

What Else Can You Think Of?

MOTIVATIONAL TECHNIQUES

Continued

Positive Reinforcement and Behavior.

This Approach Holds That Individuals Can Be

Motivated by Properly Designing Their Work

Environment and Praising Their Performance.

Holds That: Punishment for Poor Performance

Produces Negative Results.

Goal Setting With Employee Participation Is Essential.

Periodic Re-Evaluation Is Essential.

Requires Frequent Work Environment Adjustments.

Requires Detailed Planning and Training of Workforce.

MOTIVATIONAL TECHNIQUES

Continued

Employee Participation and Behavior.

People Are Motivated by Being Consulted on Actions

That Effect Them.

People Know Their Jobs.

What Safety Program

Changes Can They Bring to the Work Environment?

People In Many Cases Know the Safety Problems and

Safety Solutions. Just Ask.

Participation In The Safety Program Satisfies

Affiliation and Acceptance Needs.

Workers Must Know That Final Decisions Are

Reserved to Management.

But Tell Them Why!

ATTITUDE

MOTIVATION CHANGES ATTITUDE

AND

ATTITUDE DRIVES BEHAVIOR

When a Persons Attitude Changes, His or Her

Behavior Will Typically Follow.

Assuming He or

She Has Adequate Knowledge of the Safe Working

Conditions in the Work Environment. When You

Eliminate Every Other Reason for Unacceptable

Behavior, What Is Left It Attitudinal.

ATTITUDE IS IMPORTANT

SAFETY AS PART OF THE WORK ENVIRONMENT

If a Person Understands That His or Her Safety at

Work is Controllable in a Measurable Way,

Acceptance of Safety as an Essential Part of the

Work Environment Will Be Increased.

Safe

Attitudes and Behaviors Will Naturally Follow.

AND!

ATTITUDE IS IMPORTANT

Continued

SAFETY AND PEER SUPPORT

Once Safe Attitudes are a Normal Element in the

Work Environment, Behavior Will Be Influenced.

Then, Peers and Coworkers Expect Each Other To

Practice Safety as a Part of Work and Not a

Requirement of Work.

At This Point Coworkers Will Expect Each Other’s

Protection and Accident Rates Will Decrease.

ATTITUDE IS IMPORTANT

Continued

SUSTAINING SAFE BEHAVIOR

Management Is Responsible to Promote Safety.

Everyone is Responsible For Sustaining a Safe

Work Environment.

Attitude Is the Key To

Sustaining a Safe Work Environment.

GOOD ATTITUDE IS PREVENTION

“It is estimated that in the United States, 97% of the money spent for medical care is directed toward treatment of an illness, injury or disability. Only 3% is spent on prevention.

” Good Attitude = A

Healthier Workforce.

Self-Help Manual For Your Back

H. Duane Saunders, MSPT by Educational Opportunities

THE HUMAN FACTOR

NO ONE IS AS AN AVERAGE PERSON

Rules, Policies, Schedules, Jobs Etc., Must

Accommodate The Majority.

Focus on The Individual - Try To Please Everyone.

Good Behavior Can Be Enhanced By Accommodating

The Majority. Please As Many People As Is Practical.

Bad Behavior Should Be Studied To Determine

Causation.

THE HUMAN FACTOR

Continued

PERSONAL DIGNITY IS CRITICAL TO GOOD BEHAVIOR

People Must Be Treated With Respect No Matter

What Their Position In the Company.

Always Treat People With Respect.

Always Treat People Equally.

Assume People Will Talk. It Will Keep You Straight.

Never Ridicule Good Behavior In Jest.

Remember, It Takes Two To Argue. Draw a Line.

Walk Away From Conflict, And Address It Later.

Argue Constructively If You Must Argue.

If Safety Is Critical To The Issue, Stand Your Ground.

THE HUMAN FACTOR

Continued

CONSIDER THE WHOLE PERSON

People Are the Sum Total of Their Experience,

Combined With Their Genetic Make-up.

Reinforce Good Behavior. Discourage Bad Behavior.

Learn Your Employees Strengths and Weaknesses.

Learn Strengths, Reward Them and Use Them.

Learn Weaknesses and Help To Improve Them.

Understand That Home Life Can Overflow Into Work.

Be Prepared To Deal With Unpredictable Situations.

Understand Group Behavior Verses Personal Behavior.

TRANSACTIONAL ANALYSIS

WHAT IS TRANSACTIONAL ANALYSIS?

Transactional Analysis or TA Was Originated by

Eric Berne (Games People Play, New York: Grove

Press, Inc., 1964). TA Assumes That Each of Us

Reside in a Particular Mental (Ego) State at All

Times. These States Are:

1. Parent 2. Adult 3. Child

TRANSACTIONAL ANALYSIS

Continued

WHY IS TRANSACTIONAL ANALYSIS IMPORTANT?

TA Is Important Because When You Are Interacting

With Co-Workers You Can Quickly Recognize

Which Ego State They Are Operating in and Then

You Can Adjust Your Behavior With the Individual

Accordingly. This Will Optimize Your Interaction and Keep the Work Environment Professional and

Safe.

1. Parent 2. Adult 3. Child

TRANSACTIONAL ANALYSIS

Continued

STIMULUS VERSES RESPONSE

Effective Use of TA Requires That You Understand the Meaning of “Stimulus” and “Response”.

Stimulus: What Is Said or Done to Initiate a Response.

Response: Behavior As a Result of Stimulus.

Note: All of us interact this way every day.

TRANSACTIONAL ANALYSIS

Continued

CROSSED TRANSACTION

Stimulus (SUPERVISOR): Jim,

I’ve Got Another Press

Down, Get the Work Done on This Press Immediately, I

Don’t Care How You Do It.

Response (WORKER): I Know What I’m Doing, I Was

Working Here When You Were Still in Grade School!

Note: Completely Ineffective Transaction. Transaction is Crossed. Each Person Assumes A “Parental” State and Speaks to The Other Persons “Child”.

TRANSACTIONAL ANALYSIS

Continued

P

A

C

P

A

CROSSED

TRANSACTION

NOT VERY

EFFECTIVE

C

1. Parent 2. Adult 3. Child

TRANSACTIONAL ANALYSIS

Continued

PARALLEL TRANSACTION

Stimulus (SUPERVISOR): Jim, Another Press Just

Went Down, I’m Concerned About Production.

How

Long Do You Feel It Will Take to Safely Make Repairs on

This Press?

Response (WORKER): I Still Have to Replace a Drive

Gear. Should Be About 2 Hours. Is the Other Press a

Higher Priority Than This One?

Note: Each Person Understands The Higher Need.

Behavior Is Consistent With Safe Requirements of the

Job. Transaction Is “Adult” to “Adult” (Optimal)

TRANSACTIONAL ANALYSIS

Continued

P

A

C

STIMULUS

RESPONSE

P

A

PARALLEL

TRANSACTION

OPTIMAL

C

1. Parent 2. Adult 3. Child

TRANSACTIONAL ANALYSIS

Continued

DO YOU SEE THE VALUE IN TA?

Understanding Which Ego State a Person Is

Operating in Will Allow You To Positively Affect

Their Behavior.

Safety and Professionalism on

The Job Can Then Be Improved.

Its a Simple

Concept, With a Little Practice You Will Be Able to

Integrate This Technique Into Your Management

Style. Your Personal Life May Also Be Positively

Affected.

ACCIDENT CAUSATION

WHAT CAUSES ACCIDENTS?

?

ACCIDENT CAUSATION

Continued

USE OF A BROKEN LADDER RESULTS IN AN ACCIDENT

Contributing Factors

Was he or she properly trained?

Did the employee know not to use it?

Was he or she reminded not to use it?

Why did the supervisor allow its use?

Did the supervisor examine the job first?

Why was the defective ladder not found?

Are procedures in place for defective equipment?

ACCIDENT CAUSATION

Continued

Behavioristic Causes

Improper attitude.

Lack of knowledge or skill.

Physical or mental impairment.

I’ve Never Been

Hurt Before

Improper Attitude

ACCIDENT CAUSATION

Continued

Behavioristic Causes

Horseplay.

Defeating safety devices.

Failure to secure or warn.

Operating without authority.

Working on moving equipment.

Taking an unsafe position or posture.

Operating or working at an unsafe speed.

Unsafe loading, placing, mixing, combining.

Failure to use personal protective equipment.

ACCIDENT CAUSATION

Continued

Unsafe Conditions (Environmental)

Improper PPE.

Improper tools.

Improper guarding.

Poor housekeeping.

Improper ventilation.

Defective equipment.

Improper illumination.

Unsafe dress or apparel.

Hazardous arrangement.

ACCIDENT CAUSATION

Continued

Unsafe Personal Factors

Fatigue.

Defective hearing.

Defective eyesight.

Muscular weakness.

Lack of required skill.

Lack of required knowledge.

Intoxication (alcohol, drugs).

ACCIDENT CAUSATION

Continued

Types of Accidents

Slip, Trip.

Struck by.

Overexertion.

Struck against.

Fall on same level.

Fall to different level.

Caught in, on, or between.

Contact with - heat or cold.

Contact with - electric current.

Inhalation, absorption, ingestion, poisoning.

ACCIDENT CAUSATION

Continued

When you:

Eliminate Unsafe Environmental Conditions.

Upgrade Engineering Controls.

Optimize Administrative Controls.

Provide Adequate Personal Protective Equipment.

WHAT’S LEFT?

ATTITUDE!

ATTITUDE DRIVES BEHAVIOR

A WORD OF CAUTION

You Can’t Influence Employee Behavior If Contact Is

Too Infrequent or Limited.

Reinforcement Must

Happen Frequently. If Acceptable Behavior Is Not

Reinforced As It Happens, and If Corrective

Instruction Is Not Direct and Specific, Behavior May

Not Be Changed.

Also, Responsibility for Safety Is in No Way Shifted

Entirely From Management to the Employee. Safety

Is Still the Shared Responsibility Between

Management and All Other Company Employees.