Abstract This experiment aims to investigate the modes of vibration

advertisement

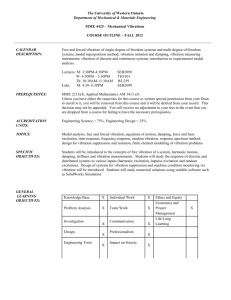

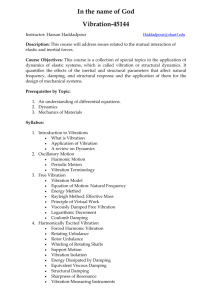

Abstract This experiment aims to investigate the modes of vibration of a trailer rig. With this, a range of instrumentation is used of varying costs and sophistication. It was discovered that this rig contained two main modes of vibration – longitudinal and rotational vibration. From the graphs, it was observed that the damping of the system is approximately linear and is most likely due to friction damping. It is sufficient to use the LVDT coupled with the digital oscilloscope for these purposes as it produces accurate results at a good price. Improvements could be made to the experiment to eliminate sources of error – large part of it having been human error – and to try to mimic the real life situation more closely. 1. Introduction The properties of the road trailer setup will be investigated using a number of instrumentation techniques with different complexities and costs. The performance of each of the techniques will be benchmarked while the most appropriate technique will be chosen and recommended. Furthermore, this report will also investigate how the experimental arrangement related to normal action of the suspension of the road. 2. Apparatus Equipment used to record and analyse the motion: Equipment Description Digital Oscilloscope To record and analyse the motion of the trailer and show the results in a graphical manner digitally on screen 7000 XY Plotter Record the motion of the trailer and show ther esults by plotting up a graph Analyses the frequency using a computational method 4000 FFT Analyser Cost ($) 10000 Table 2.1 – recording the analytical equipment and their costs Equipment used to transducer the motion of the trailer: Equipment Description LDVT Transducing the motion of trailer by varying voltages 500 Pointer and Scale Transducing the motion of the trailer 2.5 Stopwatch Measure the amount of time per period 10 Table 2.2 – Transducing Equipment and their costs Cost ($) 3. Experimental procedure Longitudinal vibration: 3.1 Method 1: Pointer Scale & Stopwatch 1. Place pointer at the end of the trailer (position1) and adjust the height of the scale to fit the pointer 2. Excite the system by applying a downward force directly at the centre of gravity of the trailer. 3. Maintain this excitation and record the number of cycles and time taken to complete 4. Excite the system by applying a singular downward force directly at the centre of gravity of the trailer. 5. Record the amplitude and period of the vibration (movement of pointer and time by stopwatch – number of cycles in a certain time). 3.2 Method 2: XY Plotter 1. 2. 3. 4. Clamp the drive rod at the end of the trailer (position 1) and insert it into the LVDT. Calibrate the LVDT by measuring a zero point with a multimeter. Adequately prepare the cy plotter (align paper, turn on servo) Excite the system by applying downward force directly at the centre of gravity of the trailer 5. The system’s displacement is recorded via the XY Plotter 3.3 Method 3: Digital oscilloscope 1. Clamp the drive rod at the end of the trailer and insert it into the LVDT. 2. Calibrate the LVDT by measuring a zer0 point with a multimeter. 3. Excite the system by applying downward force directly at the centre of gravity of the trailer 4. Save the result in a floppy disk 3.4 Method 4: Frequency Analyser (FFT) (Demonstration Only) 1. Clamp the drive rod at the end of the trailer (position 1) and insert it into the LVDT 2. Calibrate the LVDT by measuring a zero point with a multimeter. 3. Excite the system by applying downward force directly at the centre of gravity of the trailer 4. Record data obtained from the screen Rotational Vibration: 3.5 Method 2: XY Plotter 1. 2. 3. 4. Clamp the drive rod at the end of the trailer (position 2) and insert it into the LVDT. Calibrate the LVDT by measuring a zero point with a multimeter. Adequately prepare the cy plotter (align paper, turn on servo) Excite the system by applying a force couple to create a torque which in turn causes a rocking mode of vibration. 5. The system’s displacement is recorded via the XY Plotter 3.6 Method 3: Digital Oscilloscope 1. Clamp the drive rod at the end of the trailer (position 2) and insert it into the LVDT. 2. Calibrate the LVDT by measuring a zero point with a multimeter. 3. Apply a force couple to create a torque which in turn causes a rocking mode of vibration. 4. Save the result in a floppy disk 3.7 Method 4: Frequency Analysis (FFT) This method was not carried out in the experiment due to shortage of time. However, a demonstration was provided where this method was thoroughly explained. 1. Clamp the drive rod at the end of the trailer (position 3) and insert it into the LVDT 2. Calibrate the LVDT by measuring a zero point with a multimeter. 3. Apply a force couple to create a torque which in turn causes a rocking mode of vibration. 4. Record data obtained from the screen Fig 3.1 – Top View of Trailer Fig 3.2 – Front View of Trailer (How a Force Couple is Applied) 4. Results & Calculations Longitudinal Vibration: 4.1 Method 1: Pointer Scale & Stopwatch From T1which is attached in the appendix, the following data was obtained: Average No. of Oscillations 7 5 5 5.67 Time (s) 𝑥0 (mm) 1.9 1.8 1.9 1.87 23 26 29 26 Undamped Natural Frequency 𝜔𝑛 = 19.12 rad/s 𝑓𝑛 = 3.04 Hz Damped Natural Frequency 𝜔𝑑 = 19.09 rad/s 𝑓𝑑 = 3.04 Hz Logarithmic Decrement δ = 0.347 Damping Coefficient 𝜉 = 0.055 4.2 Method 2: XY Plotters From the graph obtained from the plotted (attached in Appendix), the period and displacements can be measured. The first peak of each group was neglected as it can be considered to be not of natural vibration. From the T1 (appendix), the damping coefficient for each set of vibrations was obtained. Set 1 2 3 4 Average 𝜉 0.029 0.0318 0.0384 0.0195 0.0297 Table 4.2 – Data Values from XY Plotter 4.3 Method 3: Digital Oscilloscope Two sets of data were collected for the longitudinal vibration. Calculations are made using the same formulas as in method 2 where the damping ratio can be determined using the peak values in conjunction with the following equation: 𝑋 𝑙𝑛 𝑋 𝑖 𝑖+1 𝜉= 2 √4𝜋 2 + (ln 𝑋𝑖 ) 𝑋𝑖+1 The data obtained from the oscilloscope was then translated into a graph in Microsoft Excel. Longitudinal Vibration - Set 1 Displacement (mm) 1.5 -2.5 1 0.5 0 -2 -1.5 -1 -0.5 -0.5 0 0.5 1 1.5 2Time (s)2.5 -1 -1.5 Figure 4.3.1 – Data Set 1 for Longitudinal Vibration Peak 2-3 Peak 3-4 Peak 4-5 δ 0.10 0.12 0.16 𝜉 0.03 0.04 0.05 𝜔𝑑 23.31 25.62 25.38 𝜔𝑛 23.32 25.64 25.41 δ = Logarithmic Decrement 𝜉 = Damping Coefficient 𝜔𝑑 = Damped Frequency 𝜔𝑛 = Natural Frequency Table 4.3.1 – Values obtained from Data Set 1 Longitudinal Vibration Set 2 Displacement (mm) 1.5 1 0.5 0 -2.5 -2 -1.5 -1 -0.5 -0.5 0 0.5 1 1.5 2 2.5(s) Time -1 Fig 4.3.2 – Data Set 2 for Longitudinal Vibration Peak 2-3 Peak 3-4 Peak 4-5 𝜉 0.04 0.04 0.06 δ 0.12 0.14 0.19 𝜔𝑑 23.51 25.21 25.96 𝜔𝑛 23.53 25.23 26.01 Table 4.3.2 – Values obtained from Data Set 2 4.4 Method 4: Frequency Analyser (FFT) Although this experiment was not carried out, a demonstration displaying this was explained during the laboratory. If values were to be obtained from the display of the FFT analyser, they can be used to calculate damping coefficient 𝜉. The following equations would be applied: 𝑄= Where 𝑓𝑐 = Centre Frequency 𝑓𝑙 = Lower Frequency 𝑓𝑢 = Upper Frequency 𝑓𝑐 𝑓𝑢 − 𝑓𝑙 𝜉= 1 2𝑄 Rotational Vibration: 4.5 Method 2: XY Plotter From the graph obtained from the plotted (attached in Appendix), the period and displacements can be measured. The first peak of each group was neglected as it can be considered to be not of natural vibration. From the T1 (appendix), the damping coefficient for each set of vibrations was obtained. 𝜉 0.0257 0.0283 0.0269 0.0267 0.0269 Set 1 2 3 4 average Table 4.5.1 – Damping Coefficient from XY Plot 4.6 Method 3: Digital Oscilloscope Similarly, the values obtained for the rotational vibration were with the same formula used in section 4.3. The values obtained were translated into graphs with Microsoft Excel Rotational Vibration (Set 1) 0.8 Displacement (mm) 0.6 -2.5 0.4 0.2 -2 -1.5 0 -0.5 -0.2 0 -1 0.5 1 1.5 -0.4 -0.6 -0.8 Fig 4.6.1 – Data Set 1 for Rotational Vibration Peak 2-3 Peak 3-4 Peak 4-5 δ 0.18 0.27 0.58 𝜉 0.06 0.09 0.18 𝜔𝑑 18.97 19.39 20.35 Table 4.6.1 – Values Obtained from Data Set 1 𝜔𝑛 19.01 19.47 20.68 2 2.5(s) Time Rotational Vibration (Set 2) Displacement (mm) 0.4 0.2 0 -2.5 -2 -1.5 -1 -0.5 -0.2 0 0.5 1 1.5 2 2.5(s) Time -0.4 -0.6 Fig 4.6.2 – Data Set 2 for Rotational Vibration Peak 2-3 Peak 3-4 Peak 4-5 δ 0.15 0.17 0.29 𝜉 0.05 0.06 0.09 𝜔𝑑 18.33 21.91 20.56 𝜔𝑛 18.35 21.95 20.64 Table 4.6.2 – Values Obtained from Data Set 2 5. Discussion 5.1 Modes of Trailer Vibration There are two main modes in which the trailer vibrates. The frist is a longitudinal mode of vibration which involved only a vertical motion of the trailer arms and rod, also known as a bouncing motion. Another vibration mode is a rocking manner which involved the rotational motion of the trailer arms relative to the rod. 5.2 Linearity of Damping Based on the observation of the peaks and the sequential changed of, it can be said that the damping of the system is approximately linear and mostly at the beginning of the vibration. While the force and displacement magnitudes are high, the friction in the springs is the dominant damping source. After this time, when magnitudes are sufficiently low, the springs are too stiff to deflect (threshold as mentioned later) and so the tyres take up most of the deflection at which points the curve tends to be exponential and non-linear (very slightly). Linearity of peaks Amplitude Bounce Set 1 Bounce Set 2 Rotational Set 1 Rotational Set 2 Peaks Figure 5.2.1 – Linearity of Peaks to demonstrate damping of system Due to this observation, it can be said that this is friction damping as viscous damping would give a much more pronounced exponential envelope and less of a linear curve. Additionally, due to the force required to overcome the friction threshold, the peaks would just halt in friction damping. Tyres are made of materials which exhibit hysteresis and are therefore considered non-linear dampers. Another reason is that the area in contact with the ground changes as a square of the vertical deflection. Consequently, the force exerted by the tyres on the ground is a quadratic function of vertical displacement. 5.3 Capability and Cost of Equipment for each Method 1. Pointer Scale & Stopwatch Cost is very low. However, it required at least two people to collect data; one to measure the frequency while the others take amplitude readings. This method is highly inaccurate mostly due to human errors such as reading the amplitudes, reaction time rate to stopping the stopwatch. 2. XY Plotter With the cost totalling $4500 (see Table 2.2 for details), LVDT with the XY Plotter is a relatively accurate method. However, the XY plotter has several limitations. One such limitation is the slow rate. This is a mechanical property whereby the movement of the plotter cannot proportionally demonstrate the real amplitude when the frequency is too high. For example, if the drive rod was oscillation at a very slow speed, the “pen” would move the whole length of paper. However, as the frequency increases, the “pen” is unable to cover the whole length within the short time. It was tested at the frequency of 100Hz, the pen was merely vibrating on the spot and at 1000Hz, there was no movement. Hence, the XY Plotter should be sued at low frequencies for optimum results. 3. Digital Oscilloscope This method is more accurate than the XY plotter as the vibrations are directly observed as digital data which is then plotted on the screen. It can then be scrutinized and analysed with more detail as it can be used in computer programs such as Microsoft Excel and Matlab. These machines cost approximately $7000 which is almost twice as much as an XY Plotter but is compensated for by its accuracy. 4. Frequency Analyser (FFT) This method would produce the most accurate results as it can detect both lateral and normal vibrations simultaneously and displaying these to the screen. It’s accuracy comes at a price of $10000. However, only a demonstration was carried out using this method in order to avoid any accidents as it takes time to learn its operation. 5.4 Closeness of the Experimental Arrangement Relating to Normal Action of the Suspension The experiment’s setup is no really similar to the actual scenario that may happen to a suspension system on the road. For one, the trailer rig is locked to the ground. Manually vibrating the rig may lead to inconsistencies as the force applied is not constant, thus affecting the outcome of the experiment. Moreover, the actual road may include constant smooth travelling with little vibration or rough terrain that produces a lot of vibrations or a mixture of both. 5.5 Suggestion for the Types of Equipment In regards to this experiment, the LDVT and digital oscilloscope is recommended to be used cooperatively in free vibration analysis. It is adequate in measuring natural frequency and damping coefficient in this situation. However, if the damping coefficient accuracy is not an important consideration, the XY plotter will be sufficient for a big saving. 5.6 Sources of Error There are several sources of errors. The main factor is due to human error which includes reading the amplitude from the pointer, reflex timing of the stopwatch, inconsistent rocking for the torsional vibration and the reading of f c from the FFT analyser display (it is required we take the centre of the peak different readers may read different values.) There is also quantisation errors or errors during the A/D conversion. Most equipment has an acceptable range of error. The values for f u and fl were required to be exactly 3db on either side of fc. However, due to the allowable “ruler” limitation, our values were taken at approximately 2.8 and 2.7db on either side. This may lead us to produce slightly different values of 𝜉. . The non-linearity due to friction damping may contribute to errors. The limitation of servo frequency response may not allow equipment to cope with certain levels of amplitudes. The “clipped” peak of the first peaks produced by the digital oscilloscope is due to the range allowed - this can be adjusted. There is also the presence of noise; other natural frequency sources within the system. This is shown by the jagged curve from the digital oscilloscope. For the rotational vibration, it must be noted that to obtain a more accurate curve, it is noted that the position of the drive rod is important to obtain a more accurate curve. Additionally, the method in which the system may be “rocked” may cause slight inaccuracy due to physical human error. 5.7 Improvement ideas Some improvements could be made while running the experiment. High amplitudes and frequencies should be avoided; measurements should be taken digitally to avoid human error. If using the digital oscilloscope, a low pass filter could be added to reduce noise. If taking the measurements of rotational vibration, it is best if the LVDT w as attached further away from the rig so the displacement it experiences is as accurate as possible. However, this may prove difficult as the amplitude would now increase and the LVDT’s range may not be able to cope. 6 Conclusion From experiments, this set up has two modes of vibration; rotational and longitudinal which are both approximately linear. Comparatively, it is not necessary to use highly sophisticated equipment which is much more costly than the LVDT to obtain our evaluation. Hence the most ideal method which takes cost into consideration is to use the digital oscilloscope accompanied by the LVDT. Although the results were fairly good, there were many sources of error, the largest due to human error. Improvements to this experiment could be made to decrease number of errors or try to simulate more closely the realness of the situation.