Cost Control

advertisement

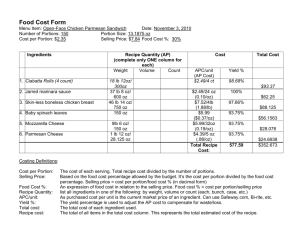

Chapter 3 Cost Control COST CONTROL Cost control is a business’s efforts to manage how much it spends Every business needs to make more money than it spends in order to survive. That is, its sales, or revenue, have to be higher than its costs. Revenue is the income from sales before expenses, or costs, are subtracted. Cost is the price an operation pays out in the purchasing and preparation of its products or the providing of its service. TYPES OF COSTS A successful restaurant or foodservice operation needs to manage and control many costs. Food costs, beverage costs, and labor costs each have components that are related to sales levels. Variable or semi-variable costs can change based on sales. These are controllable costs because the operation has a certain amount of control in how it spends on these aspects of the operation. Overhead cost is a fixed or non-controllable cost, meaning it needs to be paid regardless of whether the operation is making or losing money. Fixed costs do not change based on the operation’s sales. OPERATING BUDGET An operating budget is a financial plan for a specific period of time A fo r e ca st i s a pre di c t i o n o f s a les l evels o r c o s t s t h a t w i l l o c c ur duri n g a s pe c i fic t i m e pe ri o d. M o s t fo re c a st ing te c h n iq ues re l y o n h av ing a c c ura te h i s to ric al d a t a fo r t h e o pe ra t i on. Th e m o s t c o m mon fo o ds e r vic e reve n ue fo re c a st ing te c h n iques a re ba s e d o n t h e n um be r o f c us to m er s a n d ave rage s a les p e r c u s to me r . A s a les h is to r y i s a re c o rd o f t h e n um be r o f po r t i o n s o f eve r y i te m s o l d o n a m e n u. M o s t o pe ra t i ons c a n run h i s torical s a l es a n d pro duc t i o n re po r t s fro m t h e i r p o in t - o f - s ale ( P OS) s y s te ms . PROFIT AND LOSS REPORT A profit-and-loss report (P&L) is a compilation of sales and cost information for a specific period of time A P & L s h ows w h et h e r a n o pe ra t i on h a s m a de o r l o s t m o n ey duri n g t h e t i m e pe ri o d c ove red by t h e re po r t . Th e P & L, o r i n c o me s t a te m ent , h e l ps m a n ager s g a ug e a n o pe ra t i on’s pro fi t a bi lit y a s we l l a s c o m pa re a c t ua l re s ul t s to ex pe c te d g o a ls. A P & L a l so h e l ps m a n ageme nt dete rm i ne a re a s w h e re a dj us t ment s m us t be m a de to bri n g bus i n ess o pe ra t i ons i n l i ne w i t h e s t a blished fi n a n cial g o a ls. Fo r a n o pe ra t io n to be pro fi t a bl e , s a l es m us t exc e e d c o s t s. COST-CONTROL TOOLS Advances in technology have drastically increased the number of options available to operations in controlling costs. Software programs can be used to complete the calculations required in cost planning, controlling sales, controlling inventory, and focusing on the menu. Computer software can easily provide better access to information, more accurate and convenient collection of information, and improved analysis of that information. If used ef fectively, technology can help in running an operation more ef ficiently and helping to reduce and ef fectively control costs . SECTION 3.1 SUMMARY Every business needs to obey one basic principle to survive: it must make more money than it spends. Food costs, beverage costs, and labor costs each have components that are related to sales levels. An operating budget is a financial plan for a specific period of time. It lists the anticipated sales revenue and projected costs and gives an estimate of the profit or loss expected for the period. A profit-and-loss report is a compilation of sales and cost information for a specific period of time that shows whether an operation has made or lost money. 7 STEPS IN CONTROLLING FOOD COSTS Food costs must be controlled during all seven stages of the food flow process: 1. Purchasing 2. Receiving 3. Storage 4. Issuing 5. Preparation 6. Cooking (production) 7. Service (sale) DETERMINING FOOD COST Food cost is the actual dollar value of the food used by an operation during a certain period. Food cost includes the cost of food sold, given away, wasted, spoiled, incorrectly prepared, overportioned, overproduced, or pilfered. Inventory is the dollar value of a food product in storage and can be expressed in terms of units, values, or both: Opening inventory is the physical inventory at the beginning of a given period. The closing inventory is the inventory at the end of a given period. The formula for obtaining an actual food cost accurately is: (Opening inventory + Purchases = Total food available) – Closing inventory = Total food cost DETERMINING FOOD COST PERCENTAGE Total food cost percentage is the relationship between sales and the cost of food to achieve those sales. Analyze food cost percentage by comparing it to company standards, historical costs, or even industry standards. To determine the percentage, divide the total food cost by the sales: Total food cost ÷ Sales = Food cost percentage Food cost is a variable cost: It should increase or decrease in direct proportion to an increase or decrease in sales if all of the standards and food controls are followed correctly. ESTABLISHING STANDARD PORTION COSTS Most every operation has standardized recipes that are followed every time a menu item is prepared. For every standardized recipe, an operation should establish a standard portion cost , which is the exact amount that one serving, or portion, of a food item should cost when prepared according to the item’s standardized recipe. A recipe cost card is a tool used to calculate the standard portion cost for a menu item. As with the standardized recipe, a recipe cost card should exist for every multiple -ingredient item listed on the menu. AS-PURCHASED VERSUS EDIBLE-PORTION COSTS The as-purchased (AP) method is used to cost an ingredient at the purchase price before any trim or waste is taken into account. In the AP method, all ingredient quantities are listed on the standardized recipe in the form in which they are purchased. The edible-portion (EP) method is used to cost an ingredient after trimming and removing waste, so that only the usable portion of the item is reflected. Using the EP method to cost an ingredient, the quantity is listed on the standardized recipe using only the edible portion of that particular ingredient. 12 RECIPE YIELDS A recipe yield is the process of determining the number of portions that a recipe produces. To determine how many portions a recipe yields, calculate the total volume of the recipe either by weight or by volume, depending on how the portion size is calculated. Understanding recipe yields is one of the keys to successful food preparation and controlling food costs. The measurements given in recipes must be followed exactly. Once a yield is known and properly followed, it’s easier to increase or decrease the size of the recipe based upon the operation’s changing needs. CONTROLLING PORTION SIZES Controlling portions is very important for a restaurant to meet its standard food cost. Tools that are essential for accurate portion control include: Scoops Ladles Serving spoons Serving dishes Ramekins, bowls, cups, and so on Portion scales Another mechanism for ensuring that portions are the right size is to proportion any item that can be preportioned before serving. MONITORING PRODUCTION VOLUME AND COST When restaurants produce too much, food cost goes up; produce too little, and sales are lost. A food production chart shows how much product should be produced by the kitchen during a given meal period. A well-structured chart can ensure product quality, avoid product shortages, and minimize waste, spoilage, theft, energy costs, and administrative costs. Sales history is critical in helping management forecast how many portions of each menu item to produce on a given day. MENU PRICING The menu is the primary sales tool in most restaurant and foodservice operations. There are a number of methods for menu pricing: A contribution margin is the portion of dollars that a particular menu item contributes to overall profits. To use the contribution margin method, an operation must know the portion costs for each item sold. In the straight markup pricing method, multiply raw food costs by a predetermined fraction. With the average check method, the total revenue is divided by the number of seats, average seat turnover, and days open in one year. The food cost percentage is equal to the food cost divided by food sales. SECTION 3.2 SUMMARY Food costs must be controlled during all seven stages of the food flow process, from the actual purchasing of food items to how they are served to customers. Food cost is the actual dollar value of the food used by an operation during a certain period. Food cost percentage is the relationship between sales and the cost of food to achieve those sales. Most operations have standardized recipes that are followed every time a menu item is prepared. SECTION 3.2 SUMMARY (CONT.) Two methods used to determine the cost of ingredients in a standardized recipe are the AP method, which means “as purchased,” and the EP method, which stands for “edible portion.” A recipe yield is the process of determining the number of portions that a recipe will produce. Controlling portions is very important for a restaurant to meet its standard-food cost. The menu is the primary sales tool in most restaurant and foodservice operations. BUDGETING LABOR COSTS Labor is a semivariable, controllable cost. Labor costs are tied to sales, but not directly. Most operations have both full -time and part-time staff. Operations must be aware of the fluctuations in their sales so as to have just the right amount of staff on hand to handle customers efficiently, It is an important part of the management function to make sure that payroll cost is in line with the budgeted standard. Ideal labor cost is the standard the restaurant uses to budget for staffing needs; it represents what management predicts will happen. 3.3 LABOR COST FACTORS Business volume, or the amount of sales an operation is doing for a given time period, impacts labor costs. Employee turnover is the number of employees hired to fill one position in a year ’s time. Quality standards also affect labor cost. Quality standards are the specifications of the operation with regard to products and service. A restaurant or foodservice operation must meet operational standards. If an employee does not prepare a product that meets the operation’s standards, the item must be redone. This costs money, in terms of wasted product and lost productivity. SCHEDULING A master schedule is a template that shows the number of people needed in each position to run the restaurant or foodservice operation for a given time period. To make the best estimates for a reasonable master schedule, it also needs to consider current trends. After determining the anticipated sales, management determines the payroll dollars, which are the number of dollars available for payroll for a scheduling period. A crew schedule is a chart that shows employees’ names and the days and times they are to work. A contingency plan helps an operation remain ef ficient and productive even during adverse conditions. SECTION 3.3 SUMMARY Operations must be aware of the fluctuations in their sales so as to have just the right amount of staff on hand to handle customers efficiently. Four primary factors affect labor costs: Business volume Employee turnover Quality standards Operational standards Scheduling depends greatly on how much revenue an operation is bringing in and how much revenue an operation expects to bring in. QUALITY STANDARDS FOR PURCHASING AND RECEIVING Purchasing: Prior to ordering, receiving, and storing quality products, consider where the products were grown or produced. Those with purchasing responsibility should seek suppliers who are considered to be ethical, reliable, and financially stable. Receiving: Once purchase orders have been made, the next step is to receive the item in the most efficient, safe, and effective way possible. Well-defined receiving procedures ensure that an operation receives only the products that meet its established standards for quality and quantity. QUALIT Y STANDARDS FOR STORING Storing: It’s critical that operations create quality standards for proper storage. Monitor perishable food daily to preserve its quality. Some food items have manufacturer ’s recommendations for storing the product. Store food with proper labels, and rotate all products in storage following the FIFO (first in, first out) system. In addition to checking the food in the storage facilities, the storage facilities themselves should be checked regularly to make sure they are clean and functioning properly and efficiently. QUALIT Y STANDARDS FOR FOOD PRODUCTION AND SERVICE Standard-portion sizes, standardized recipes, and standard portion costs are all food -production standards. It is important that managers ensure that standards are met throughout the foodservice cycle. It is important that operations have quality assurance measures in place right up to the service stage of the food flow process. The key to identifying deviations from standard recipes and presentations is regular monitoring and the understanding by the staff that it is the responsibility of everyone in the establishment to ensure quality. QUALIT Y STANDARDS FOR INVENTORY Taking physical inventory means counting and recording the number of each item in the storeroom. Closely monitor inventory to ensure that products are ordered as they are needed. Carefully monitoring inventory also helps ensure that no product goes to waste. Minimizing waste keeps costs down and sales up. Determine actual food costs by opening and closing inventories for a given period. Use the latest purchase price (FIFO), actual purchase price, weighted average purchase price, or last in, first out (LIFO) method to determine the value of the closing inventory. 3.4 SECTION 3.4 SUMMARY It is important to take cost -control measures in all aspects of the food flow process, from purchasing to service. Standardizing food production helps to ensure quality standards as well, because each item is gauged on one standard. Closely monitor inventory to ensure that products will be ordered more efficiently as they are needed.