View Content - DAIDS Learning Portal

advertisement

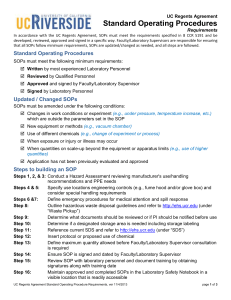

Testing Facilities Operation Version 5.0 August 2012 This project has been funded in whole or in part with Federal funds from the Division of AIDS (DAIDS), National Institute of Allergy and Infectious Diseases, National Institutes of Health, Department of Health and Human Services, under contract No. HHSN272201200009C, entitled NIAID HIV and Other Infectious Diseases Clinical Research Support Services (CRSS). Objectives 2 Describe why testing facilities are required to have Standard Operating Procedures (SOPs) List the elements of an SOP List the elements of an effective document control plan Describe the elements of an effective SOP distribution plan Pre-Assessment Question #1 Which of the following correctly describes why testing facilities are required to have SOPs? A. To ensure the quality and integrity of the data generated B. To guide the auditors in monitoring work performed at a testing facility C. To explain procedures that are to be performed in a laboratory, except for waived or rapid tests 3 Pre-Assessment Question #2 Information related to the assay’s reportable range would likely be found in which of the following elements of an SOP? A. B. C. D. E. 4 Principle/purpose Specimen Procedural steps Limitations Calculations Pre-Assessment Question #3 Which of the following should be discussed in a document control plan? A. Reviewing the SOPs periodically and revising them when necessary B. Identifying superseded documents and archiving them to prevent inadvertent use C. Maintaining a master SOP list D. Removing obsolete SOPs E. All of the above 5 Pre-Assessment Question #4 Which of the following should be considered when developing an effective SOP distribution plan? A. A good document control system B. Encourage staff to have personal copies of SOPs C. Redistribute original and revised versions as needed 6 The Regulations State… A testing facility shall have standard operating procedures in writing setting forth non clinical laboratory study methods that management is satisfied are adequate to insure the quality and integrity of the data generated in the course of a study... 21 CFR § 58.81 – 58.90 7 SOP Guidelines 8 Each laboratory should have SOPs for ALL procedures being performed SOPs are written for the benefit of the laboratory employees, not auditors SOPs should be written in a manner and language that is appropriate to the laboratory personnel conducting the procedures Current SOPs must be available in the work areas and accessible to staff Document Control Information included in Document Control SOP Number Number of pages Approval signatures with dates Names, signatures, and dates of all personnel Revision number and date 9 Signature List Signature and Initial List 10 Employee Name Signature Initials Date Tiri Towindo Tiri Towindo TT 12-Jul-02 Michael Stirewalt Michael Stirewalt MS 06-Jan-00 Standard Operating Procedures What should be included in an SOP? 11 SOP Title Title of the Procedure Name of the analyte Type of specimen Specific method and/or instrumentation Example: Serum/Plasma Glucose Determination Using the Olympus AU 600 12 Standard Operating Procedure Elements Principle and/or Purpose Instrumentation Quality Control References Author 13 Specimen Recommendation/ Collection Methods Reagents, Standards, Controls, and Media Used Procedural Steps Calculations Reporting Results Limitations Effective Date/Review Schedule Distribution Standard Operating Procedure Elements (cont’d) Principle and/or Purpose Specimen Recommendation/ Collection Methods Reagents, Standards, Controls and Media Used List in paragraph form the typeSteps of reaction and the Instrumentation Procedural Calculations reasons for performing the test. Quality Control Reporting Results Limitations Example: The glucose method is an adaptation of the hexokinase-glucose-6-phosphate dehydrogenase method, presented as a general clinical laboratory method by Effective Date/Review References Distribution Kunst, et al.1 This methodSchedule is more specific than general reducing methods and will give results lower than those Authorby such reducing methods2. obtained 14 Standard Operating Procedure Elements (cont’d) Principle and/or Purpose Specimen Recommendation/ Collection Methods Reagents, Standards, Controls and Media used • Conditions for study participant preparation Instrumentation Procedural Steps • Specific specimen type • Handling conditions Quality Control Criteria Reporting Results Rejection • Mislabeled • Leaking/broken Effective Date/Review References • Hemolysed, lipemic,Schedule icteric Calculations Limitations Distribution Example: Normal procedures for collecting and storing Author serum, plasma, urine, and cerebrospinal fluid may be used for samples to be analyzed by this method. 15 Standard Operating Procedure Elements (cont’d) Principle and/or Purpose Specimen Recommendation/ Collection Methods Reagents, Standards, Controls and Media Used • Instrumentation List reagents, standards, controls, and mediaCalculations employed Procedural Steps • Indicate directions for preparation • List parameters that determine acceptable performance Quality Control Reporting Results Limitations Example: All reagents and materials for this test are stored in the glass door refrigerator (at 2 – 8°C) located in the Effective Date/Review References Distribution Schedule chemistry department. Overflow reagents are stored in the gray door refrigerator (at 2 – 8°C) located in the chemistry department. Author 16 Standard Operating Procedure Elements (cont’d) Principle and/or Purpose Instrumentation 17 Specimen Recommendation Standards, • List equipment used inReagents, the procedure /Collection Methods Controls and Media Used • Include calibration protocols and schedules Procedural Steps Calculations Example: The following information should be considered Quality Control Reporting Results when calibrating the GLU method: Limitations • Assay Range: 0–500 mg/dL • Reference Material: Primary standards or secondary Effective Date/Review References calibrators such as CHEM I Calibrator (Cat.Distribution No. DC18) Schedule • Suggested Calibration Levels: 0, 250, 425 mg/dL • Calibration Scheme: Three levels in triplicate Author • Calibration Frequency: Every new reagent cartridge lot and every 3 months for any one lot • Assigned Coefficients: C00.000 C1 0.880 Standard Operating Procedure Elements (cont’d) • Detailed Specimen Recommendation/ Reagents, Standards, • Stepwise Principle and/or Purpose Collection Methods Controls and Media Used • Appropriate for personnel conducting the procedure Instrumentation Procedural Steps Calculations Example: Instructions for Processing Samples, Bar Coded Quality Control Reporting Results Limitations Tubes Place bar code labels on tube. 10 mL tubes may be put Effective Date/Review References Distribution directly in a segment with Schedule the bar code facing the bar code reader. 7 mL and 5 mL tubes must be placed in appropriate adaptors. Brown adaptors are for 7 mL tubes; green Author adaptors are for 5 mL tubes. Check for sufficient sample volumes using the tube fill gauge. 18 Standard Operating Procedure Elements (cont’d) Principle and/or Purpose Specimen Recommendation/ Collection Methods • Give stepwise instructions Instrumentation Procedural Steps • List any applicable equations • Give precise examples Quality Control Reporting Results Reagents, Standards, Controls and Media Used Calculations Limitations Date/Review References Distribution Example: To manuallyEffective calculate Low Density Lipoprotein Schedule Cholesterol (LDLC), use the following equation: LDLC = [TC] - [HDLC] - [TG/5] Author 19 Standard Operating Procedure Elements (cont’d) Principle and/or Purpose Instrumentation Quality Control References Author 20 Reagents, Standards, • Identify the control material used Controls and Media Used • List preparation and handling instructions Procedural Steps Calculations • List frequency of analysis • Establish and explain tolerance limits and state corrective actionLimitations for values Reporting Results outside tolerance limits Specimen Recommendation/ Collection Methods Effective Date/Review Distribution Example: At least once daily, run Schedule solutions of a quality control material at two levels with known concentrations Standard Operating Procedure Elements (cont’d) Principle and/or Purpose Specimen Recommendation/ Collection Methods Reagents, Standards, Controls and Media Used • State the reference range • Identify procedures for reporting abnormal results Instrumentation Procedural Steps Calculations • Give guidelines on acceptable report format Quality Control Reporting Results Limitations Example: Serum and Plasma results are reported in mg/dL Effective Date/Review References Distribution Schedule and are rounded to the nearest tenth Normal range: 72-112 mg/dL PanicAuthor values: <50 or >350 mg/dL for adults; <40 or >350 mg/dL for babies 21 Standard Operating Procedure Elements (cont’d) • Example: Specimen Recommendation/ Principle and/or Purpose Collection Methods 1. Assay Range: 0–500 mg/dL 2. Hemoglobin of 500 mg/dL • Instrumentation Procedural Steps falsely depresses GLU results by 20 mg/dL at 131 mg/dL of glucose Quality Control Reporting Results 3. Bilirubin of 20 mg/dL falsely depresses GLU results by 12 Effective Date/Review mg/dL at 124 mg/dL glucose References Schedule 4. Lipemic (triglyceride 600 mg/dL) samples falsely elevate GLU Author results by 10 mg/dL at 129 mg/dL of glucose 22 State linearity Reagents, Standards, and/or detection Controls and Media Used limits State known Calculations interferences Limitations Distribution Standard Operating Procedure Elements (cont’d) List items used as sources of information Specimen Recommendation/ Principle and/or references Purpose • Literature Collection Methods • Manufacturer product literature • Textbooks Instrumentation Procedural Steps • Written personal communications • Standards publications Use Standard Bibliographical format Quality Control References Author 23 Reporting Results Reagents, Standards, Controls and Media Used Calculations Limitations Example: 1.Kunst A, Draeger B, and Ziegenhorn J. UVEffective Date/Review methods with hexokinase and glucose-6Distribution Schedule phosphate dehydrogenase, Methods of Enzymatic Analysis, Vol VI, Bergmeyer HU (ed.) Verlag Chemie, Deerfield, FL 1983:163-172 2.Henry RJ. Clinical Chemistry Principles and Technics, New York: Harper and Row, 1974:1283 Standard Operating Procedure Elements • Performed by authorized Specimen Recommendation/ Reagents, Standards, Example : Principle and/or Purpose personnel Collection Methods Controls and Media Used Review Revision Signature • Review when changes Date Date are made Instrumentation Procedural Steps Calculations • Review annually • Document review • Remove obsolete or Reporting Results Limitations Quality Control superseded procedures References Author 24 Effective Date/Review Schedule Distribution Standard Operating Procedure Elements (cont’d) Specimen Recommendation/ • Document control Collection Methods • Keeps track of number of copies Principle and/or Purpose Instrumentation Procedural Steps Distributed To Quality Control Reporting Results Limitations Effective Date/Review Schedule Distribution Example: References Author 25 Reagents, Standards, Controls and Media Used Number of Calculations Copies Standard Operating Procedure Elements (cont’d) Principle and/or Purpose Specimen Recommendation/ Collection Methods Reagents, Standards, Controls and Media Used Instrumentation Procedural Steps Calculations Reporting Results • Quality TakeControl credit for your work • Keep track of the number of copies References Author 26 Effective Date/Review Schedule Limitations Distribution Document Control Plan 27 The SOPs should be reviewed periodically and revised when necessary Superseded documents should be identified appropriately and archived to prevent their inadvertent use Master SOP list Remove obsolete SOPs Document Control Plan (cont’d) Authorization Process Establish who has authority to conduct a review 28 May vary based on the administrative structure Skill Check How often should the review of SOPs be documented? A. B. C. 29 Every two years Annually Only when changes are made Document Control Plan Annual Reviews Ensures Procedures are Current Document Review Practice vs. Procedure 30 Standard Operating Procedure Training 31 All personnel need to be instructed on new procedures or changes to procedures Documentation that all personnel are knowledgeable of the contents of the SOP Post-Assessment Question #1 Which of the following correctly describes why testing facilities are required to have SOPs? A. To ensure the quality and integrity of the data generated B. To guide the auditors in monitoring work performed at a testing facility C. To explain procedures that are to be performed in a laboratory, except for waived or rapid tests 32 Post-Assessment Question #2 Information related to the assay’s reportable range would likely be found in which of the following elements of an SOP? A. B. C. D. E. 33 Principle/purpose Specimen Procedural steps Limitations Calculations Post-Assessment Question #3 Which of the following should be discussed in a document control plan? A. Reviewing the SOPs periodically and revising them when necessary B. Identifying superseded documents and archiving them to prevent inadvertent use C. Maintaining a master SOP list D. Removing obsolete SOPs E. All of the above 34 Post-Assessment Question #4 Which of the following should be considered when developing an effective SOP distribution plan? A. A good document control system B. Encourage staff to have personal copies of SOPs C. Redistribute original and revised versions as needed 35 References DAIDS Guidelines for Good Clinical Laboratory Practice Standards. FDA 42 C.F.R. § 493: Laboratory Requirements (Clinical Laboratory Improvement Amendments, CLIA). 42 CFR § 493.1251 42 CFR § 493.1407 42 CFR § 493.1105 36 College of American Pathologists Commission on Laboratory Accreditation, Accreditation Checklists, April 2007. Clinical and Laboratory Standards Institute (CLSI). Laboratory Documents: Development and Control; Approved Guideline-Fifth Edition. GP2-A5 (2006). NCCLS. Continuous Quality Improvement: Integrating Five Key Quality System Components; Approved Guideline-Second Edition. GP22-A2 (2004). Wrap Up 37