Silicon Carbide Presentation

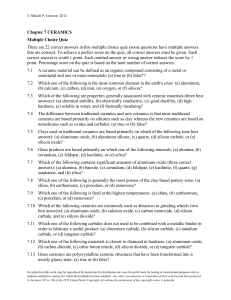

advertisement

Discovery In 1891 Edward G Acheson produced a small amount of Silicon Carbide while conducting experiments with the aim of obtaining a hard material from the reaction of clay and carbon. He passed a strong electric current from a carbon electrode through a mixture of clay and coke contained in an iron bowl, which served as the second electrode. Acheson recognized the abrasive value of the crystals obtained, had them analyzed, found the formula to be SiC, incorporated The Carborundum Company in September 1891, and filed application for a patent on May 10, 1892. SiC Properties Silicon Carbide is also called carborundum, including black and green silicon carbide both with a shape of hex crystal. The black silicon carbide is classified into coke-made and coal-made black silicon carbide depending on different raw materials. The material is extremely hard and sharp, with excellent chemical properties. The hardness is between diamond and fused alumina, but the mechanism hardness is higher than fused alumina. The micro hardness is in the range of 2840-3320kg/mm². Silicon Carbide is sharp but fragile with good heat-resistance, heat-conductibility, can be antacid and antalkali, lower dilatability and can be aseismatic. SiC has: high hardness high thermal consistency very good resistance at high temperatures low thermal expansion electrical conductivity is a semiconductor non linear electrical resistance Si and C as alloying additive SiC Properties cont. Crystal Structure of Silicon Carbide Appearance: When removed from the furnace, the Silicon Carbide is a mass of interlocking iridescent crystals, the crystals themselves being largely twinned and often coalescent. Their iridescence is due to a thin surface layer of silica resulting from superficial oxidation of the carbide. Washing in hydrochloric acid will remove this layer. The crystals vary in colour from very pale green to black depending on the amount of included impurities. Hardness: Silicon Carbide was the first material entering the range of hardness between corundum and diamond. It is given the relative position of 9.5 on Mohs scale and diamond at 10. Properties: SiC is quite stable chemically. It is stable to acids, not reacting with fuming nitric acid, nor with boiling sulphuric hydrochloric or hydrofluoric acid. Sodium silicate attacks it above 1300ºC, calcium and magnesium oxides attack above 1000ºC. Copper oxide reacts at 800ºC to form the metal silicide. It oxidizes slowly in air above 1000ºC. Silicon Carbide dissociates in molten iron and the silicon reacts with the metal oxides in the melt. This reaction is of use in the metallurgy of iron and steel. Applications for SiC Silicon carbide forms natural crystals, which are very hard, very abrasive and dissociate or sublimate at high temperatures. It is for these reasons that silicon carbide is used in the following applications: Abrasive Industry With a good hardness, silicon carbide is the first choice raw material for manufacturing abrasive pipe, impeller, pumping chamber etc. Its abrasiveness is 5-20 times than that of cast iron and rubber. Macrogrits are used to make items like sandpaper, grinding wheels, disks, wire saws and a number of other abrasive products. Applications for SiC cont. Refractory Industry Because of its high temperature and abrasive resistance it is used to make refractories for furnaces and other high temperature components. The ceramic industry is one of the largest users of SiC refractory products. Metallurgical Industry Silicon carbide is used for the deoxidation and recarburation of cast iron and steel in foundries. Metallurgical grade Silicon Carbide grain is a unique material for use in the production of iron and steel. It is used in the foundry industry for the electric furnace production of gray, ductile, and malleable iron. It is an excellent source of carbon and silicon, promotes nucleation and renders the iron more responsive to inoculation, and deoxidizes the iron, which enhances furnace lining life. Silicon carbide can also be used to enhance efficiency in ferroalloy production using the patented Maxred process developed by Sublime Technologies. Other Industries Silicon carbide is used in several specific electro-technical applications such as autovalves andresistance. It is also used in traditional mechanical fields such as non-slip floors. Silicon carbide is also being used for a number of new technologies and advanced materials such as special ceramics that are used to line the space shuttle to protect it during its re-entry into the earth’s environment. It is also used to make revolutionary new materials for Components such as brake disks with an indefinite lifespan. Typical Silicon Carbide uses Fixed and moving turbine components Suction box covers Seals, bearings Ball valve parts Hot gas flow liners Heat exchangers Semiconductor process equipment Sublime Technologies (Pty) Ltd. History Sublime Technologies is South Africa’s first silicon carbide producer. Sublime originated within Pyromet Technologies (now Tenova Pyromet), an organisation specialising in smelting technology. Sublime was established in 2001 and produces Silicon Carbide making use of state of the art Acheson Electric furnaces (diagram). The company exports most of it production to consumers in Europe with only a small percentage being used in South and Southern Africa. Sales into America have now also started and will increase as production increases. Products are crushed and screened into various size fractions where after it is sold in bulk and bagged format. Scope exists for producing more value added variations of the current products in future which will enhance margins. Our marketing team in North America and Europe have extensive experience in all areas of silicon carbide production and sales. Sublime has taken advantage of South Africa’s low electricity costs – its first furnace was commissioned in January 2003 with a 10 megawatt furnace and the second furnace was commissioned in May 2008 incorporating a 16 megawatt furnace. Sublime third furnace is 95% completed and ready to be commissioned. The inclusion of the third furnace will increase production to 3300tons per month. Production Process Silicon carbide is made today in much the same way as it was when invented in 1891: High purity quartz is mixed with a high quality coke or anthracite in large electric resistance furnaces at temperatures of over 2 000°C according to the following reaction: SiO2 +3C=SiC +2CO Coke Coal Silica The process is an endothermic reaction requiring between 8 000 – 10 000kWh per tonne of product. The product is removed from the furnace when cool and separated into different grades. Sorting is aimed at separating high-grade crystalline silicon carbide from metallurgical grade silicon carbide. Furnace Crushing & Screening Met Grade SiC 85% 15% Crystalline Grade SiC Lower grades of silicon carbide are recycled in the production system. The sorted silicon carbide is then crushed and screened to a saleable product. Products we produce Crystalline Grade (98%) Our premium quality product has a variety of applications ranging from abrasives, (bonded, coated and granular), refractories and metallurgical applications. Products are uncompromisingly precision graded & packaged to customer specifications. Metallurgical Grade (82% - 92%) Our production process inherently produces grades of silicon carbide with lower SiC content, material ideally suited to re carburetion of cast iron and steel in foundries. Metallurgical grade Silicon carbide can also be used to enhance efficiency in ferroalloy production using the patented Maxred process developed by Sublime Technologies. Maxred Process: In terms of Maxred there is currently no rival to this process from other technologies. The alternative for ferrochrome users would be to revert to the conventional carbon reduction process and hence have no additional benefits that the Maxred process allows. Testing of the material has shown strong potential, but pricing and limitations of Sublime’s ability to supply have retarded market penetration. The increased volumes from the expanded plant as well as a much lower unit production costs can be expected to result in market growth in this area. New Developments Pelletising: Silicon Carbide can be used in the production of Ferrochrome. Currently Silicon Carbide is added directly into Ferrochrome furnaces but new research by the company is suggesting that by adding the product into the Chrome ore pellets which are used to charge Ferrochrome furnaces, significant improvements in Ferrochrome production recoveries and efficiencies may be possible. To this end improved furnace recovery techniques are being trialed in conjunction with local major steel producers, which are showing encouraging results.