slide

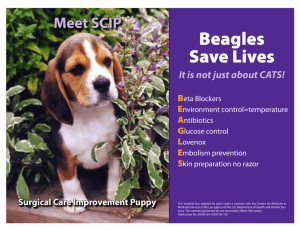

advertisement

Razor: Dynamic Voltage Scaling Based on Circuit-Level Timing Speculation Dan Ernst, Nam Sung Kim, Shidhartha Das, Sanjay Pant, Rajeev Rao, Toan Pham, and Conrad Ziesler Faculty Members: David Blaauw, Todd Austin, and Trevor Mudge, The University of Michigan Krisztián Flautner, ARM Ltd. 36th International Symposium on Microarchitecture (MICRO-36’03) Outline Introduction What is Razor? Razor error detection/correction Experimental Evaluation Previous Work Conclusion Introduction (1/2) The need for DVS (Dynamic Voltage Scaling) Critical supply voltage Traditional DVS adds many margins Worst-case may be data-dependent and very rare Process variations and other variabilities worsen the required margins Introduction (2/2) Idea Instead of trying to avoid ALL errors, ALLOW some errors to happen and correct them! Cost of fixing errors is minimal when the error percentage is kept under control Tune processor voltage based on monitoring error rate What is Razor? Razor Timing Error 4 9 3 clk MEM Shadow Latch clk 5 Main FF Main FF Razor Timing Error Detection 9 clk_del Second sample of logic value used to validate earlier sample Key design issues: Maintaining pipeline forward progress Short path impact on shadow-latch Meta-stable results in main flip-flop Recovering pipeline state after errors Power overhead of error detection and correction Hold Constraint (~1/2 cycle) 4 2 9 8 clk MEM Shadow Latch clk 5 3 Main FF Main FF Razor Short Path Constraint 8 clk_del Min. path delay > Tdelay + Thold Meta-stability in main FF Key design issues: Maintaining pipeline forward progress Short path impact on shadow-latch Meta-stable results in main flip-flop Recovering pipeline state after errors Power overhead of error detection and correction Centralized Razor Pipeline Error Recovery Cycle: 1 0 6 5 4 3 2 clock recover recover error recover MEM error Razor FF error EX Razor FF ID Razor FF PC IF Razor FF inst2 inst5 inst4 inst3 inst1 inst6 WB (reg/mem) error recover Once cycle penalty for timing failure Global synchronization may be difficult for fast, complex designs Distributed Razor Pipeline Error Recovery Cycle: 7891234560 bubble recover Flush Control flushID error recover flushID bubble MEM (read-only) error bubble recover flushID error Stabilizer FF error EX Razor FF ID Razor FF PC IF Razor FF inst2 Razor FF inst5 inst2 inst1 inst6 inst8 inst7 inst4 inst3 bubble recover flushID Multiple cycle penalty for timing failure Scalable design since all recovery communication is local Builds on existing branch / data speculation recovery framework WB (reg/mem) Error Rate Studies – Empirical Results 100.0000000% 10.0000000% 1.0000000% 0.1000000% 0.0100000% 35% energy savings with 1.3% error 22% saving random 0.0010000% 0.0001000% 0.0000100% 0.0000010% 0.0000001% 0.0000000% 1.78 1.74 1.70 1.66 1.62 1.58 1.54 1.50 1.46 1.42 1.38 1.34 1.30 1.26 1.22 1.18 1.14 Environmental-margin @ 1.69 V Zero-margin @ 1.54 V Supply Voltage (V) once every 20 seconds! Error rate 18x18-bit Multiplier Block at 90 MHz and 27 C Error Rate Studies – SPICE-Level Simulations Based on a SPICE-level simulations of a Kogge-Stone adder Kogge-Stone Adder at 870 MHz and 27 C 100.00% 1.00% 0.10% random bzip 200 mV 0.01% ammp 0.00% 2 1.8 1.6 1.4 1.2 Supply Voltage 1 0.8 0.6 Error rate 10.00% EX-Stage Analysis – Optimal Voltage Sweep Recovery cost includes energy to recover entire pipeline (18x an add) BZIP 1.4 Rel Energy Rel Performance 1 0.8 0.6 0.31% Error Rate, 58% Energy Savings 0.4 Voltage 0.6 0.65 0.7 0.75 0.8 0.85 0.9 0.95 1 1.05 1.1 1.15 1.2 1.25 1.3 1.35 1.4 1.45 1.5 1.55 1.6 1.65 1.7 1.75 0.2 1.8 Relative IPC and Energy 1.2 EX-Stage Analysis – Optimal Voltage Sweep GCC 1.4 Rel Energy Rel Performance 1 0.8 0.6 1.62% Error Rate, 24% Energy Savings 0.4 Voltage 0.6 0.65 0.7 0.75 0.8 0.85 0.9 0.95 1 1.05 1.1 1.15 1.2 1.25 1.3 1.35 1.4 1.45 1.5 1.55 1.6 1.65 1.7 1.75 0.2 1.8 Relative IPC and Energy 1.2 Simulation Analysis – Energy-Optimal Voltage 120 Percentage of Baseline (zero-margin) 100 80 Total Energy IPC 60 40 20 0 bzip crafty eon gap gcc gzip mcf parser twolf vortex vpr Average Supply Voltage Control System Simulation Analysis – Razor DVS Execution GCC 2 40.00% Voltage Error Rate 1.8 35.00% 1.6 30.00% 25.00% 1.2 1 20.00% 0.8 15.00% 0.6 10.00% 0.4 5.00% 0.2 0 0.00% Time Error Rate Supply Voltage 1.4 Simulation Analysis – Razor DVS Performance 120 Percentage of Baseline (zero-margin) 100 Total Energy DVS Energy IPC DVS IPC 80 60 40 20 0 bzip crafty eon gap gcc gzip mcf parser twolf vortex vpr Average Previous Work Conclusion Razor advantages Eliminate safety margins Operate at sub-critical voltage for optimal trade-off Tune voltage for average instruction data Paper writing Very detailed experiment steps Good survey about previous DVS work