Capstone 2012-2013 PolarCube CDR

advertisement

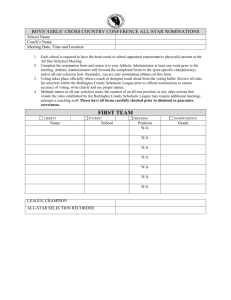

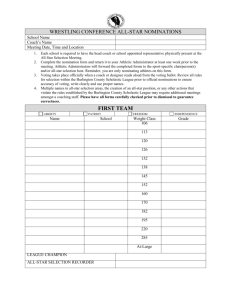

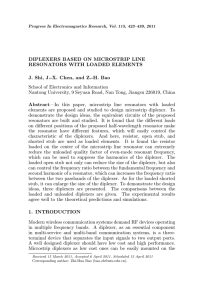

Capstone 2012-2013 PolarCube CDR December 11, 2012 2 Microwave Sounding Frequency vs. Zenith Opacity • PolarCube will use 118.75 GHz, a resonance frequency of diatomic oxygen, as a center frequency Courtesy of Dr. Gasiewski • PolarCube Channels have a specified weights corresponding to altitude Courtesy of Lavanya Periasamy, University of Colorado 3 ALL-STAR Satellite Bus 4 Block Diagram of the Bus and Payload 5 Block Diagram 6 RF Block Diagram 7 RF Block Diagram 8 RF Block Diagram 9 IF Block Diagram 10 Function Before Digital 11 Function of Radio Frequency (Channel 5) T=(F-1)T0 P=kTB Attenuator( switch) Isolator Mixer(Mixer & local Oscillator) Low noise amplifier(LNA) Noise Figure(dB) 0.6 0.6 5.1 1.18 7.08 Noise Temperature(K) 42.96 42.96 527.3 90.53 1121.59 NP(dBm) L/G(dB) Output of RF -57.38 L=0.6 L=0.6 L=2.8 G=28.7 Function of Intermediate Frequency Noise Figure(dB) Diplexer Amplifier( 3) Attenuator( 2) 1 2.40 3.06 2.5 1.2 213.96 296.67 225.70 92.29 2.81 -3.30 -11.82 -13.02 G=20.4 L=3.06 L=2.5 L=1.2 Noise Temperature(K) Noise Power(dBm) Loss/Gain(dB) L=1 Power Splitter Filter Tunnel Diode -13.02 IF System 14 Diplexer Motivation • • • Multi-channel radiometer needs channel separation in order to measure different frequency band The diplexer splits the signal from RF Receiver into two bands 15 Diplexer Design The design problem is much more difficult than it might at first seem. If ordinary low-pass filter and high-pass filter are simply connected together, interaction effects will usually disrupt the performance of the system, unless the filters and their interconnections are very carefully designed. To prevent this disruption, the complementary structure is very correct technique to design a 16 diplexer. Complementary Structure We construct diplexer with LPF and HPF to have complementary input admittances and connects them in parallel. The complementary input admittances means that the sum of the input admittance of the low pass and high pass filter are real and constant for all frequencies. Hypothetical input admittances of LPF and HPF is shown in the figure.17 Schematic of Diplexer 18 Idea Value VS. Real Value None of component manufacturer produces ideal component value. They produce limited discrete value and various size 19 ADS Test Bench 20 Performances Ideal Value Real Value 21 Sum of Imaginary Part of Impedance Ideal Value Real Value -0.1 1.3 1.3 22 Diplexer PCB Layout 23 IF System • Two IF boards, in two carriers • The diplexer connected to the IF higher frequency circuit board(right hand box) Courtesy of Space Grant Consortium, University of Colorado 24 * 25 * IF System Risk Management • • • Physical constraint (shrink down the size of PCB boards) Pre-amp signal oscillation problem (old design) Fit in the video-amp board 26 Pre-Amp board and Oscillations 3-Amp Board Spectrum Analyzer Plot Have the peak in plot with 0 RF input signal 27 2-Amp & 3-Amp board 28 Video-Amp Layout Video Amp Board Signal Video Amp IF Board 29 IF Block Diagram 30 Digital Board Block Diagram 31 Digital Hardware • • • • Provides capability for communication over SPI with the ALL-STAR bus, for transmitting data and accepting/sending commands Flash memory as needed for data queuing and workspace before transfer to ALL-STAR Provides capability to sample the analog output of the IF system Includes voltage regulators to provide necessary voltages to digital components 32 Software • • • • Responsible for initiating and collecting samples from the output of the ADCs, communicating with ALL-STAR, and switching necessary components off during low-power availability ALL-STAR server Must compress data for transmission during downlink window Manage power for components via control input to voltage regulators 33 SLOC 34 Digital Risk Management • Utilizing established Atmel SPI APIs to interact with digital hardware for quicker development • SVN SCM for distributed development and change tracking • • Incremental hardware design strategy Familiarization with software while hardware is being developed 35 Xplained Board • • • • Risk mitigation strategy Has allowed for familiarization with Atmelprovided SPI and GPIO APIs while test hardware is still being designed and ordered Have used to verify the needed steps in getting one of the SPI interfaces to interact with Aardvark protocol analyzer Familiarized with GPIO API for potential future use during power management 36 Modular Test Board Designs for Memory and ADCs Memory Test Board ADC Test Board 37 Digital Board Physical Constraints 38 Power Constraints Power Supply Lines to Active Components in the Payload 39 Power Constraints and Preliminary Power Budget • • • Payload Power Supply: Nominally 4 - 5 W Oscillator: 4.875W Full Power Draw All Components: ~11W 40 Power Modes FSM 41 Data Budget 42 Monetary Budget 43 Timeline 44 Acknowledgements Special Thanks to: Dr. Gasiewski Brian Sanders and the team at Space Grant Lavanya Periasamy Kyuil Hwang 45 Questions?