Presentation_slides

advertisement

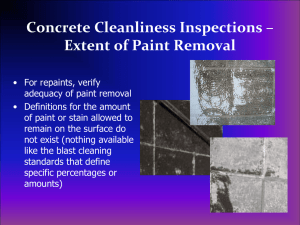

Standards, Training, and Certification in the Oil and Gas Industry Presented by: Ernst Toussaint, TransCanada Introduction • The purpose of this webinar is to describe how to properly specify a coating system for a specific substrate (steel, metal, previously coated), structure and environment by specifying specific industry standards, training and certifications to ensure a quality project. What is a Specification? • A detailed coating specification is a complex and sometimes confusing document to navigate. Yet, it is the rulebook for QC and QA personnel responsible for inspecting work. Specification • Each coating specification for a steel structure should start with: – SSPC Technical Insight Report: Preparing and Using Protective Coating Specifications – SSPC PA 1 SSPC Technical Insight Report: Preparing and Using Protective Coating Specifications • The purpose of this report is to describe some best practices for preparing and administering a quality specification for application of high performance protective coatings and linings for the oil and gas industry. SSPC-PA 1 • SSPC-PA 1, Shop, Field, and Maintenance Painting of Steel Surface Preparation • Dual Purpose: Cleaning the surface Roughening the surface Surface Cleanliness Standards • • • • SSPC and NACE issue consensus standards Currently SSPC has issued 13 cleanliness standards NACE is jointly referenced in 7 of the 13 International Standardization Organization (ISO) also publishes hand tool, power tool and abrasive blast cleaning standards SSPC-SP1, Solvent Cleaning • Requires the removal of all visible grease, oil, lubricants, cutting compound and other nonvisible contaminants from the surface • Degreasing agents (solvents, alkaline and emulsion cleaners, steam cleaning) described earlier • Mechanical cleaning will not remove grease/oil • “Indirect requirement” to the SSPC surface cleanliness standards SSPC-SP2, Hand Tool Cleaning • SSPC-SP1 (solvent cleaning) is an “indirect requirement” • Requires removal of all loosely adhering rust, mill scale and paint • Remaining materials must be tightly adhering • Contract may require feathering • No surface profile requirement • Visual verification using SSPC VIS 3 – Excellent tool to “calibrate” eye and aid in establishing project standard SSPC-SP3, Power Tool Cleaning • Requires removal of all loosely adhering rust, mill scale and paint • Remaining materials must be tightly adhering (dull putty knife test) • No surface profile requirement SSPC-SP11, Power Tool Cleaning To Bare Metal • Requires: Removal of all loosely and all tightly adhering mill scale, rust and paint to expose the bare metal surface (traces of paint, rust and mill scale can remain in bottom of pits) A minimum 25 µm (1 mil) anchor pattern • Prepared surfaces should not be compared to abrasive blast cleaned surfaces Surface roughness characteristics are different SSPC-SP15, Commercial Grade Power Tool Cleaning • Requires removal of all loosely and tightly adhering mill scale, rust and paint • Staining from rust, paint and mill scale permitted but must not exceed 33% (one third) of each 58 cm2 (9 in2) of prepared surface • Traces of paint, rust and mill scale can remain in bottom of pits • Minimum 25 µm (1 mil) anchor pattern Power Tool Cleaning-General • SSPC-SP1 (solvent cleaning) is an “indirect requirement” of SP3, SP11, SP15 • Weld slag, flux and fume deposits should be removed from welds (per contract documents) • Verify removal of dirt/debris generated by power tool cleaning (blow down, brush, vacuum) – If blow down, verify cleanliness of compressed air (“indirect requirement” of SP3, SP11, SP15) Abrasive Blast Cleaning Standards • Listed from lowest to highest level of cleanliness required • Specification must stipulate the required depth of the surface profile • • • • • SSPC-SP7/NACE 4 SSPC-SP14/NACE 8 SSPC-SP6/NACE 3 SSPC-SP10/NACE 2 SSPC-SP5/NACE 1 Dry Abrasive Blast Cleaning • Selecting the correct type and size of abrasive Too small abrasive – surface profile too shallow Too large abrasive – surface profile too deep Test abrasive size selected prior to production for surface profile yield Blast Cleaning Abrasives • Two broad categories – Expendable (used once and then discarded) – Recyclable (breakdown rate is low, permitting multiple use) Specifications for Mineral & Slag Abrasives • SSPC AB 1, Mineral and Slag Abrasives • SSPC AB 2, Cleanliness of Recycled Ferrous Metallic Abrasives • SSPC AB 3, Ferrous Metallic Abrasive • SSPC AB 4, Recyclable Encapsulated Abrasive Media(in a compressible cellular matrix) SSPC-SP7/NACE No. 4, Brush-off Blast Cleaning • “Brush blasting” the surface • Removal of all loosely adhering materials • Remaining materials tightly adhering, dull putty knife test • Contractor must exercise care if roughening existing coating SSPC-SP14/NACE No. 8, Industrial Blast Cleaning • Requires removal of all loosely adhering rust, mill scale and paint and removal of 90% of all tightly adhering materials • Evenly distributed islands of intact mill scale, rust or paint (up to 10%) may remain* • Staining is unlimited • Project specification may invoke feathering of remaining “islands” of coating *Remaining materials tightly adhering per dull putty knife test SSPC-SP6/NACE No. 3, Commercial Blast Cleaning • Requires removal of all loosely and all tightly adhering mill scale, rust and paint • Staining from rust, paint and mill scale permitted, but must be evenly distributed • Staining cannot exceed 33% (one third) of each 58 cm2 (9 in2) of prepared surface SSPC-SP10/NACE No. 2, Near-White Blast Cleaning • Requires removal of all loosely and all tightly adhering mill scale, rust and paint from the surface • Staining from rust, paint and mill scale permitted, but must be evenly distributed • Staining cannot exceed 5% of each 58 cm2 (9 in2) of prepared surface SSPC-SP5/NACE No. 1, White Metal Blast Cleaning • No loosely or tightly adhering materials may remain • No staining is permitted SSPC/NACE Waterjetting Standards • SSPC-SP WJ-1/NACE WJ-1, Clean to Bare Substrate • SSPC-SP WJ-2/NACE WJ-2, Very Thorough Cleaning • SSPC-SP WJ-3/NACE WJ-3, Thorough Cleaning • SSPC-SP WJ-4/NACE WJ-4, Light Cleaning Water Jetting - General • Water jetting cannot generate surface profile (can restore existing profile) • If surface profile required, alternative surface preparation methods are required • Wet abrasive blast cleaning can generate surface profile Water Jetting - General • Establish project-specific cleanliness standards • Visual verification using SSPC VIS 4/NACE VIS 7 or SSPC VIS 5/NACE VIS 9 – Prepared surfaces rarely match visual guides – Excellent tool to “calibrate” eye and aid in establishing project standard – Use described later Evaluating Flash Rusting • SSPC VIS 5/NACE VIS 9 illustrates 3 levels of flash rusting: – Light (L) – Medium (M) – Heavy (H) • NSRP Flash Rust Guide SSPC Paint Application Standards • SSPC-PA 2, Procedure for Determining Conformance to Dry Coating Thickness Requirements • SSPC- PA 17, Procedure for Determining Conformance to Steel Profile/Surface Roughness/Peak Count Requirements Additional Industry Standards • NACE RP0399, Plant Applied External Coal Tar Enamel Pipe Coating Systems: Application, Performance, and Quality Control • NACE RP0602, Field Applied External Coal Tar Enamel Pipe Coating Systems: Application, Performance, and Quality Control Additional Industry Standards • NACE SP0394, Application, Performance, and Quality Control of Plant Applied Fusion Boned Epoxy (FBE) External Pipe Coating • RP0402, Field Applied Fusion Bonded Epoxy (FBE) Pipe Coating Systems for Girth Weld Joints: Application, Performance, and Quality Control Additional Industry Standards • NACE RP0303, Field Applied Heat Shrinkable Sleeves for Pipelines: Application, Performance, and Quality Control • NACE SP0490, Holiday Detection of Fusion-Bonded Epoxy External Pipeline Coatings of 10-30 mils Additional Industry Standards • SP0185, Extruded Polyolefin Resin Coating Systems with Soft Adhesives for Underground or Submerged Pipe • RP0375, Wax Coating Systems for Underground Pipeline Systems QP Certifications What is QP Certification? • A proven way for facility owners and specifiers to evaluate contractor capabilities to perform quality blasting and application work for coating projects • Certified contractors will have the experience, knowledge and equipment to produce high quality work Why Certified Contractors? • Certified contractors are experienced with a demonstrated history and competence on protective coatings projects. • Assurance that projects will be completed within your specifications. • Lower risks of safety, health, and costly environmental compliance violations. Types of SSPC QP Certification • • • • • • • QP 1 – Field Application of Coatings QP 2 – Field Removal of Hazardous Coatings QP 3 – Shop/Fixed Coating Operations QP 5 – Coatings Inspection Company QP 6 – Contractor Metalizing Certification QP 8 – Coating/Surfacing to Concrete QP 9 – Architectural Paints and Coatings Training/Certification Programs Coating Application Specialist (CAS) A joint standard of SSPC/NACE designed to certify craft workers who have experience and training on all aspects of surface prep and coating application. (meets ISO 17024) Training/Certification Programs Abrasive Blasting Program (C7) Contractor worker training that covers surface preparation, cleanliness, profile, and abrasives. Course includes exam, equipment setup, abrasive blasting, and safety meeting. Training/Certification Programs Airless Spray Basics (C12) Contractor worker training on airless spray equipment operation. Course includes use of a paint simulator, exam, materials, equipment, and a hands-on application assessment. Training/Certification Programs Protective Coatings Specialist (PCS) The Protective Coatings Specialist (PCS) is a professional certification that identifies individuals mastery in knowledge, principles and practices of industrial protective coatings technology. Training/Certification Programs Protective Coatings Inspector (PCI) Protective Coatings Inspector certification provides training in methods of inspection for protective coatings and linings. PCI Level 2 meets ASTM IS D3276 “Standard Guide for Painting Inspectors”, IMO Performance Standard for Protective Coatings, IACS SRC. Summary • By being aware of industry standards, training and certifications you can properly specify a coating system for a specific environment and structure to ensure a quality project