File - Jonas Alexander

advertisement

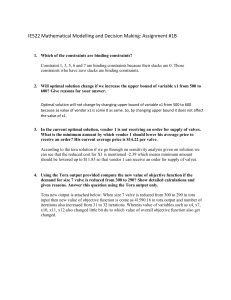

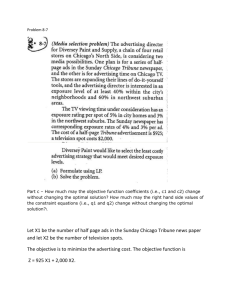

IE 3520 Group Project 12/11/2013 by Justin Alexander Jonas Alexander Introduction For this group project, we were given the option of choosing a problem from our homework assignments to model and solve by using TORA. Because these problems are fairly basic in nature, we were tasked with adjusting our chosen problem in a way that would reflect a real world situation. The problem that we chose dealt with a company that manufactures three products and uses one raw material to make them. After solving this problem with TORA, we will present the optimal solution which demonstrates the optimal product mix and profit. In the real world, most companies manufacture more than one product and use a variety of raw materials. Therefore, we will increase the number of products produced to ten and the number of raw materials to six. We will then increase the number of constraints to fifty in stages so that we can analyze the impacts to the optimal solution as they are added. Problem Selection and Solution For this project, we decided to work the problem 3.6 C number 3 from the Book. The problem read as follows, “A company produces three products A, B, and C. The sales volume for A is at least %50 of the total sales of all three products. However, the company cannot sell more than 75 units of A per day. The three products use one raw material, of which maximum daily availability is 240 lb. The usage rates of the raw material are 2 lb. per of unit A, 4 lb. per unit of B, and 3 lb. per unit of C. The Unit prices for A, B, and Care $20, $50, and $35 respectively.” So we found the objective function: Z= 20A + 50B +35C S.T. A -.5A +.5B +.5C <= 0 <= 75 2A + 4B + 3C <= 240 So the next step we took was solving the problem with TORA, and we found iteration 3 to be optimal. Here are the iterations from TORA: The optimal solution was A&B = 40, and C = 0 so Z= $2800 Stage 1 Problem Scale Up We now have decided to scale up this problem to make it more realistic. So we created the variables A-J, along with 20 additional constraints. We also created a new objective Function: Z = 20A + 50B + 35C +30D + 40E + 45F +25G + 32H +38I + 39J The 23 constraints include five dealing with sales volume, twelve detailing raw material usage in the production of certain products, and six that describe sales volume relationships between certain products. For instance we set the sales volume for product B equal to half the amount of the sum of products B, D, and E. This creates the constraint: -5B + .5D +.5E <= 0 (as shown in constraint 6). We set a sales volume limit of product B to 90 units per day which created the constraint: B <= 90 (as shown in constraint 4). We also set a raw material usage mix for products B, C, and D which created the constraint: 3B + 4C + 3D<= 200 (constraint 7). It took 15 iterations to get to an optimal solution. The max value is Z = $4,979.79 and the objective value contributions of each product are listed in the far right column. Stage 2 Problem Scale Up For this stage of the scale up, we created 15 more raw materials mixtures. For instance, in constraint 17 the raw material availability is a maximum of 150 lbs. and consists of 2 lbs. of product C, 4 lbs. of product F, and 2 lbs. of product H. This creates the constraint: 2C + 4F + 2H <= 150 It took 14 iterations to get to a final optimal solution. The max value is Z = $4,979.79 and the objective value contributions are listed in the far right column. Stage 4 Final Problem Scale Up Now we scaled up the problem one more time creating 15 more raw materials, having a total of 50 constraints. We checked to see if the final situation was feasible, and since TORA stated iteration 14 was optimal, we know the entire situation is plausible. The max value is Z = $4,901.49 and the objective value contributions are listed in the far right column. Sensitivity Analysis The sensitivity analysis determined the min and max values of the RHS that will maintain the optimality of our solution. It also showed the corresponding min and max values of the objective coefficients. Products H and J were not recommended to be made and as such have a reduced cost of 19.67 and 10.27 respectively. The dual price for product B is $53.75 which means that a unit increase in the production of product B will result in a reduction of revenue of $53.75. The analysis lists the remaining existing dual prices that are applicable within their min and max ranges.