Session 5 Warehousin..

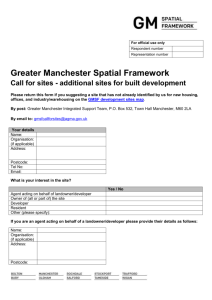

advertisement

Introduction into Logistics PhD Natasha Lutovinova Logistics Lecturer E-mail: Lutovinova.N@nhtv.nl Room: G1.006 Handbook: Paul R. Murphy & Donald F. Wood, Contemporary logistics (New Jersey 2011), 10th edition 3 Introduction into Logistics Course Outline 12.05 Introduction 13.05 SCM Concept, Inventory 14.05 Demand Management, Warehousing Management 15.05 Transportation Management, International Logistics 16.05 Poster Session CHAPTER 10 Warehousing Management 5-5 Learning Objectives • To understand the role of warehouses and distribution centers in a logistics system • To identify the various types and functions of warehouses • To distinguish the various alternatives available in warehouse design • To examine the different types of handling equipment available 6-5 Visser, Logistics: Principles, fig.1.8 cost structure of physical distribution 7-5 Cost structure of physical distribution Warehousing, packaging, handling External transport Others Inventory costs 22% 38% 6% 34% Warehousing Management Transportation at zero miles per hour 8-5 • Warehousing emphasizes storage of products • Distribution centers emphasize rapid movement of products through the facility • Throughput is the amount of product entering and leaving a facility in a given time period • Regrouping function: • - Accumulating (bulk making)(increasing quantity) • - Allocating (bulk breaking) (reducing quantity) 9-5 Figure 10-2: Ideal facility for pure supplier consolidation (Full pallet movement) 10 - 5 Fig. 10-1 Adding a Warehousing Facility: shorter-Haul Transporation 11 - 1 Producer (Manufacturing) Warehouse facility (Inventory) Sales Retailer A Transportation (Distribution) Retailer B Retailer C Warehousing management Retailer A Transportation (Distribution) (Volume shipment) Transportation (Distribution) Retailer B Retailer C Visser, Logistics: Principles, fig.10.4 Overview of the warehouse function Incoming transport Receipt + inspection Put away Storage Order picking Inspection + inspection Outbound transport 12 - 5 Overview of the warehouse functions Warehouse functions Figure 7-7: The Transportation Manager Consolidates Shipments Whenever He or She Can 13 - 5 Public, Private, Contract, and Multiclient Warehousing • Private warehousing – Owned or occupied on a long-term lease – Offers control to owner – Assumes both sufficient demand volume and stability so that warehouse remains full – High fixed costs 14 - 5 Public, Private, Contract, and Multiclient Warehousing • Public warehousing – Public warehouses – Occupational Safety and Health Administration (OSHA) – Bonded storage warehouses – Field warehousing 15 - 5 Public, Private, Contract, and Multiclient Warehousing • Contract warehousing – Contract warehousing (3PL warehousing) is a long-term arrangement providing unique warehousing services to one client – Both vendor and client share the risks associated with the warehousing – Less costly than private warehousing and more costly than public warehousing 16 - 5 Public, Private, Contract, and Multiclient Warehousing • Multiclient warehousing – Multiclient mixes attributes of contract and public warehousing – Limited number of customers 17 - 5 Design Considerations in Warehousing • General considerations – Quantity and character of goods must be known— product profiling – Know the purpose to be served • Storage • Distribution • Cross-docking 18 - 5 Design Considerations in Warehousing • Trade-offs – Product / material – What will be moved? – Quantity / volume – How much will be moved? – Route process sequence - Where will be moved to? – Supporting services – Which support will the movements be made with? – Time – When will the movements be made? 19 - 5 20 - 5 Design Considerations in Warehousing • Trade-offs • Fixed versus variable slot locations for merchandise – Fixed slot location – Variable slot location 21 - 5 Design Considerations in Warehousing – Build out (horizontal) versus build up (vertical) – Order-picking versus stock-replenishing functions – Two-dock versus single-dock layout – Space devoted to Aisles versus Space Devoted to Storage – Paperless Warehousing • Virtual warehouse versus real warehouse – Retail Storerooms 22 - 5 Warehousing Operations • • Storage and handling equipment Warehouse management systems (Auto ID Data Capture technology: barcode scanners, mobile computers, Wireless LANs, RFID) • Employee safety – Proper handling of waste materials • Dunnage • • • • 23 - 5 Hazardous materials Warehousing security Sanitation issues Stock controls 24 - 5 Figure 10-8: Workplace safety issues 25 - 5 Warehousing Operations • Labor-intensive versus mechanization versus automation • Space devoted to aisles versus space devoted to storage • Picker-to-part versus part-to-picker systems 26 - 5