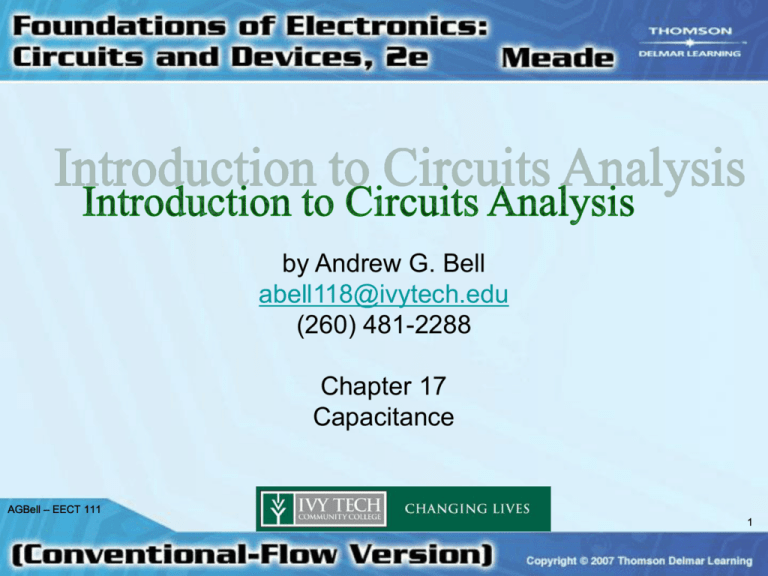

Lecture 17

advertisement

by Andrew G. Bell abell118@ivytech.edu (260) 481-2288 Chapter 17 Capacitance AGBell – EECT 111 1 Capacitor • An electrical component consisting of two conductors (plates) separated by an insulator (dielectric) • A component that opposes a change in circuit voltage AGBell – EECT 111 2 Dielectric Materials Vacuum Air Paper Plastic Glass Ceramic Aluminum Oxide Tantalum Oxide AGBell – EECT 111 3 Electrical Definition of Capacitor • An electrical component that stores energy in the form of electrical charge when voltage is applied AGBell – EECT 111 4 Basic Symbols AGBell – EECT 111 5 Capacitor Action • Applied voltage forces electrons onto one plate. The electrostatic field associated with a charged particle forces electrons off of the opposite plate. kQ1 Q2 F 2 d AGBell – EECT 111 6 Capacitor Charging • Applied voltage causes circuit current to flow. Plates of the capacitor become charged as one plate accumulates electrons and the other releases electrons. Circuit action continues until: VC = VS AGBell – EECT 111 7 Capacitor Discharge • A charged capacitor will discharge when a path is provided between the two plates. • The plate with excess electrons will give up electrons to the plate with a deficiency until: VC = 0 V AGBell – EECT 111 8 The Farad • Capacitance is the capacity of a capacitor to store electrical charge. • The unit of measure is the farad (f). AGBell – EECT 111 9 Charge and Voltage Q C V Q C V Q V C AGBell – EECT 111 10 Energy Stored in Field CV 2 Energy 2 Energy = joules stored C = capacitance (farads) V = voltage AGBell – EECT 111 11 Factors and Value ITEM Plate area Plate distance Dielectric material RELATIONSHIP Direct Inverse Direct AGBell – EECT 111 12 Dielectric Constant 0 k v 0: Absolute permittivity of dielectric materials v: Absolute permittivity of vacuum AGBell – EECT 111 13 Dielectric Types AGBell – EECT 111 14 Dielectric Strength • The breakdown voltage rating of a given material and dimensions • Dielectric material reaches point where punch-through occurs AGBell – EECT 111 15 Capacitor Formula 8.85 A C 12 10 s Use Excel to evaluate how Area, Spacing and dielectric constant change the capacitance of a parallel plate capacitor C = capacitance (farads) A = area of plates (sq. meters) s = spacing between plates (meters) 8.85 = constant for air/vacuum Excel AGBell – EECT 111 16 Finding Total Capacitance • For series capacitors: – Sum of the reciprocals 1 CT 1 1 1 1 C1 C2 C3 Cn AGBell – EECT 111 17 Finding Total Capacitance (cont.) • For two series capacitors: – Product-over-the-sum C1 C2 CT C1 C2 AGBell – EECT 111 18 Finding Total Capacitance (cont.) • For parallel capacitors: – Direct summation CT C1 C2 Cn AGBell – EECT 111 19 Total Capacitance C1 10µF Using Excel calculate the total capacitance of each circuit C2 22µF CT C3 47µF Excel C1 10µF C2 22µF C3 47µF CT AGBell – EECT 111 20 Series Voltage Distribution CT VX VS CX VX = voltage across capacitor x VS = DC source voltage CT = total series capacitance CX = value of capacitor x AGBell – EECT 111 21 Example Use Multisim determine the voltage across each capacitor Multisim Multisim AGBell – EECT 111 22 Charge Distribution • In parallel circuits: Q C V AGBell – EECT 111 23 RC Time Constant () • Time required for a capacitor to charge or discharge 63.2% of the change in voltage level applied • Five time constants are needed to fully charge/discharge AGBell – EECT 111 24 Time Constant Chart AGBell – EECT 111 25 R= 1.0E+3 ohms C = 47.0E-6 farad = 47.0E-3 seconds 5 = 235.0E-3 seconds pulse width = 235.0E-3 seconds period = 470.0E-3 seconds Assuming a 9V Square wave input Use Multisim and Excel to determine the RC Time Constant and plot the transient response Excel Multisim AGBell – EECT 111 26 Exponential Form for Charging Capacitors v R VS t = epsilon (or 2.71828) t = time allowed (seconds) = R × C (or 1 time constant) AGBell – EECT 111 27 Exponential Form for Discharging Capacitors vR VS 1 t = epsilon (or 2.71828) t = time allowed (seconds) = R × C (or 1 time constant) AGBell – EECT 111 28 Capacitor Types FIXED Paper/Plastic Mica Ceramic Electrolytic Chip VARIABLE Trimmer Air AGBell – EECT 111 29 Ratings • • • • • • Temperature Tolerance Voltage Rating Temperature Coefficient Power Factor Inductance Characteristics (at high frequencies) AGBell – EECT 111 30 Safety • Always discharge circuit capacitors after power has been removed and before working on circuits containing them. • Observe polarity when connecting electrolytic capacitors into a circuit. AGBell – EECT 111 31 Ratings • • • • • • • Physical Size and Mounting Capacitance Value Capacitance Tolerance Working Voltage Ratings Temperature Range Temperature Coefficient Inductance AGBell – EECT 111 32 Typical Problems Ohmmeter Tests Opens Shorts AGBell – EECT 111 33