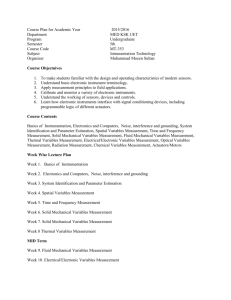

Automation Module 01 - Intro & Instrumentation (EFC 2011).

advertisement

Automation Module Engineering Foundation Course 2011 Contributors to the Course Steven Laycock: Technology Leader for Process Control and Automation in Unilever Europe since 2003 and the Global Engineering Excellence Team. Joined Unilever (Leeds) in 1996, after working for an independent systems integrator. Stuart Dow: Systems Development Manager with Haden Freeman Ltd. (engineering design and consultancy company). 13 years as engineer & manager working on projects in a variety of industry sectors. Karam Rehani: Head of Instrumentation & Controls in Unilever India & AAMET since 1994. Joined Unilever (HLL) in 1981 & has worked at various locations manufacturing soaps, detergents, personal products & chemicals. Before joining Unilever, worked for 9 Yrs with Leading fertiliser co’s in India. Adhi Winata K : Instrumentation, Control, Automation & Electrical Manager in Unilever Indonesia. Joined Unilever in 2006. Before joining Unilever, worked with telecommunication company. Endress + Hauser : Live Product Demo Rockwell Automation : Live Product Demo Siemens : Totally Integrated Automation Concept (Presentation Content) Objective What are we going to cover today 3 key areas - Understanding of the use of control systems - Key knowledge necessary to manage an automation project - Reasons to choose from the control options available Agenda Section 1: Introduction to Control Building blocks – Measurement & Action Example Equipment (Endress & Hauser) Section 2: Building Blocks – Evaluation & Logic Pack Line Case Study : OMAC (Rockwell) Section 3: Automation Projects & Industry Standards Process Plant Case Study : Implementation of ISA S88 & ISA S95 (Rockwell) Section 4: Multiple Choice Questionnaire Agenda Section 1: Introduction to Control Building blocks – Measurement & Action Example Equipment (Endress & Hauser) Section 2: Building Blocks – Evaluation & Logic Pack Line Case Study : OMAC (Rockwell) Section 3: Automation Projects & Industry Standards Process Plant Case Study : Implementation of ISA S88 & ISA S95 (Rockwell) Section 4: Multiple Choice Questionnaire Reasons for Automation Quality : Better quality, fewer rejects Marketing: A marketing push may require increased production, re-branding, re-packaging or new formulations for example, or a requirement to search for new growth or markets Commercial: Higher output, lower utility costs, better yield, less labour It is to realize highest productivity enhancements by intelligently connecting quality, speed, and cost and finding the optimal balance between all three Challenge for Automation Automation Characteristics Safety for humans & machines : • Safety Interlock • Alarm Management • Safety Integrated Solutions (SIS) Diagnostic functionalities that enable fast detection and correction of errors : • Maintenance Station • Engineering Station Software for Controller and HMI programming : • STEP 7 (Siemens) • RSLogix 5000 (Allen-Bradley) Standard data transparency across all automation levels : • Communication Protocol • Logger / Historian • Report IT Security in the network : • Restricted Access • Firewall • Encoding • VPN Network Industrial capability equipment with highest robustness : • Industrial Type Hardware Automation System Components The Automation Pyramid ERP Enterprise Resource Planning System Basic functions of the business. Production Planning, Material Management MES Manufacturing Execution System Measure and control critical production activities. Equipment tracking, product genealogy, scheduling, KPI monitoring SCADA “Supervisory Control & Data Acquisition” System Interface to monitor & control the manufacturing plant HMI, Data Logger / Historian, Batch Management Control Level Monitor & control the manufacturing plant PLC - “Programmable Logic Controller”, PC Based Controller, Single / Multiple Loop PID (Proportional, Integral, Derivative) Controller Field Level Final executor of the manufacturing plant Sensors, Actuators, I/O Module, Hardware Automation System Components Response time and hierarchical level ERP Planning Level (Enterprise Resource Planning) MES Execution Level (Manufacturing Execution System) SCADA (Supervisory Control and Data Acquisition) Supervisory Level DCS (Distributed Control System) Control Level PLC (Programmable Logic Controller) ms seconds hours days weeks month years Automation System Components Layer ERP Function Covers all basic functions of the business Application Example Product Example • Production Planning SAP • Orders Oracle • Finance • Material Management MES Measure and control critical production activities • Equipment tracking SIMATIC IT • Product genealogy FactoryTalk Integrator • Scheduling InSQL • KPI monitoring • Workflow SCADA Control Field Interface to monitor & control the manufacturing plant Monitor & control the manufacturing plant Final executor of the manufacturing plant • Operator Station WinCC, FT View, InTouch • Engineering Station • Batch Control SIMATIC Batch, FTBatch, InBatch • Logger • PLC SIMATIC S7-400, ControlLogix • PID Controller SIPART, Eurotherm T640 • PC Based Controller ACCOSS (Invensys Integrator) • Motion Controller, CNC SIMOTION, SINUMERIK • I/O Module SIMATIC ET200 M, Flex I/O • Field Instruments E+H, Emerson, SITRANS • Actuator Motor, Valve Automation System Components Application Example : Siemens Totally Integrated Automation Production Planning Production Order Management Event Logger HMI Client Batch Client Material Management Detailed Production Scheduling Data Logger Server Product Specification Management HMI Server Batch Server Production Operations Recording Automation System Components Real Plant Example : Skin Care Processing Plant Cikarang Basics How Do We Control? Information Monitor Evaluate Action Basics An Everyday Example We monitor the temperature. Is it too cold or too hot? If so we adjust the tap to correct. Wait for a bit (system dynamics) If temperature OK then have shower Else if temperature not OK adjust again (but with benefit of knowing impact of last adjustment) Go to ‘Wait for a bit’ and repeat. Basics Control Loop Instrumentation Engineering Foundation Course 2011 Agenda Section 1: Introduction to Control Building blocks – Measurement & Action Example Equipment (Endress & Hauser) Section 2: Building Blocks – Evaluation & Logic (Process & Packing Line) Pack Line Case Study : OMAC (Rockwell) Section 3: Automation Projects & Industry Standards Process Plant Case Study : Implementation of ISA S88 & ISA S95 (Rockwell) Section 4: Multiple Choice Questionnaire Building Blocks: Measurement & Action I. Monitoring & measurement 1. Process Instrumentation • • • • • Flow Measurement Level Measurement Temperature Measurement Pressure Measurement Analytical Measurement 2. Packing Line Sensors II. Action 1. Process Instrumentation 2. Packing Line Actuators III. Hardware Selection : Which to Pick Building Blocks: Measurement & Action I. Monitoring & measurement 1. Process Instrumentation • • • • • Flow Measurement Level Measurement Temperature Measurement Pressure Measurement Analytical Measurement 2. Packing Line Sensors II. Action 1. Process Instrumentation 2. Packing Line Actuators III. Hardware Selection : Which to Pick Flow Measurement 1. Velocity Measure the velocity flowrate Example : Magnetic Turbine Ultrasonics 2. Inferential Determine flow by measuring some other physical property such as differential pressure, area meter, impact force, etc and then correlate it to flow Example : Differential Pressure (DP) : Orifice, Pitot Tube, Venturi Area Meter : Rotameter Impact Force : Target 3. Mass Measure the mass flowrate Example : Coriolis Mass Flowmeter Thermal Mass Flow Measurement 1. Velocity Flow : Magnetic Flowmeter • A magnetic field at right angles to the flow stream is generated • Two opposing electrodes measure the voltage produced by the fluid moving Flow Measurement 1. Velocity Flow : Magnetic Flowmeter Video Time !!! Flow Measurement 1. Velocity Flow : Magnetic Flowmeter Advantages : 1. 2. 3. 4. 5. Capable of handling extremely low flow Having very low pressure drop (no obstruction), minimize pumping cost Suitable for most acids, bases, waters, and aquaeous solutions, because the lining materials are corrosion resistant Widely used for slurry services Can be used as bidirectional meters Limitations : 1. 2. 3. Work only with conductive fluids (can not measure pure substances, hydrocarbons, and gases) Electrical installation care is essential (Proper Grounding) Flow measurement inaccuracy due to fluids with magnetic properties (Liquid Sodium and its solutions) Flow Measurement 1. Velocity Flow : Turbine/Paddlewheel A rotor (like a propeller) is supported by bearings to allow free rotation in the fluid flow. As the blades spin in the moving flow a pickup device counts the passing rotor blades and generates a frequency. As this frequency is proportional to the rate of flow and we know how much quantity each pulse represents we can calculate the volumetric flow. Flow Measurement 1. Velocity Flow : Turbine/Paddlewheel Advantages 1. 2. 3. One of the most accurate flow meter (use for trading) Having a fast response Not sensitive to changes in fluid density (though at very low specific gravities, rangeability may be affected) Limitations 1. 2. 3. 4. Not recommended for measuring steam Sensitive to dirt Can not be used for highly viscous fluids or for fluids with varying viscosity Potential for being damaged by over-speeding (esp. during commissioning or start up) Flow Measurement 2. Inferential Flow : dP Orifice Plate Orifice plate : a flat piece of metal with a hole bored in it. p+ p- A dP (differential pressure) is created across the plate. Q C d Aorifice A 1 orifice A pipe 2 2 ( p p ) D d Flow Measurement 2. Inferential Flow : dP Orifice Plate An instrument that can measure dP is connected by pipework (called impulse lines) to a tapping point on either side of the plate. The square root of the dP measured is proportional to the flow. (Normally accounted for in the electronics of the measuring instrument) Flow Measurement 2. Inferential Flow : dP Orifice Plate Video Time !!! Flow Measurement 2. Inferential Flow : dP Various Pitot Tube Venturi Tube Flow Nozzle Elbow Taps Flow Measurement 2. Inferential Flow – dP Various Type Orifice Advantages Limitation Wide range of applications Low accuracy Simplest & cheapest among dp types (except big size) High irrecoverable pressure loss Sturdy Pitot Tube Applicable for measurement of large flows Low accuracy Can be used to obtain the velocity profiles Depend much on velocity profiles in one point Very Low pressure loss Venturi Tube Low Pressure Loss More expensive than orifice Resistant to abrasion Installation is more difficult Can be used to measure dirty fluids & slurry Elbow Taps Venturi Nozzle Low cost solution for large pipe Inaccurate measurement Very Low Pressure Loss Requiring high flow velocities & short radius elbow Less expensive than venturi tube Higher Pressure Loss than venturi tube Resistant to abrasion Installation is more difficult Flow Measurement 3. Mass Flow : Coriolis Effect Tube(s) are forced to oscillate at their natural frequencies perpendicular to the flow direction. The resulting Coriolis forces induce a twist movement in the tubes which is measured and is related to the mass flow. Flow Measurement 3. Mass Flow : Coriolis Effect Video Time !!! Flow Measurement 3. Mass Flow : Coriolis Effect Two most common types are the Straight Tube 1. 2. 3. 4. Used mainly for multiphase fluids and for fluids that can coat or clog since the straight type can be easily cleaned Having a low pressure loss Reduces the probability of air and gas entrapment Must be perfectly aligned with the pipe Curved Tube 1. 2. 3. 4. 5. Having a wider operating range, measures low flow more accurately Available in larger sizes Tends to be lower in cost Having a higher operating temperature range More sensitive to plant vibrations Flow Measurement 3. Mass Flow : Coriolis Effect Advantages : • Directly measures mass flow with high accuracy • High rangeability • Directly measure density • Highly independent of the flow profile and fluid properties (specific gravity and viscosity) • Can be used for many different applications, including corrosive fluids Limitations : • High Price • Can not be used for liquids with any significant gas content • Not available for large pipelines • Not suitable for low pressure gases Flow Measurement Other Methods Vortex Shedding Ultrasonic Thermal Mass Flowmeter Variable Area / Rotameter Weir & Flume Target Flow Measurement Flowmeter Comparison Table Flow Measurement Flowmeter Comparison Table (cont’d) Building Blocks: Measurement & Action I. Monitoring & measurement 1. Process Instrumentation • • • • • Flow Measurement Level Measurement Temperature Measurement Pressure Measurement Analytical Measurement 2. Packing Line Sensors II. Action 1. Process Instrumentation 2. Packing Line Actuators III. Hardware Selection : Which to Pick Level Measurement 1. Pressure / Force Pressure Buoyancy Force : Differential pressure, Diaphragm, Air bubblers : Displacer 2. Position (height) of the surface Wave Nuclear radiation Electrical Properties Mechanical Contact 3. Weight Load Cells : Radar, ultrasonic, Guided Radar (TDR) : Capacitance, Conductance : Floats, Tuning fork, Paddle wheel Level Measurement Pulse 6 GHz Radar Pressure Guided Wave Radar TDR FMCWPulse Capacitance 24 GHz Radar Ultrasonic Level Measurement 1. Pressure Static Head Pressure/Static Head: (also known as hydrostatic) - Based on the height of the liquid head & the density of the liquid - Accurate level calculation requires known & constant density Atmospheric Vessel Pressurized Vessel Advantages : 1. Have a wide range of measurement 2. Straightforward calibration Limitations : 1. Affected by changes in liquid density (only for liquids with fixed SG) 2. Susceptible to dirt or scale entering the tubing Level Measurement 2. Position of Surface : Wave Wave is transmitted to target, reflected, and total transit time is determined Type Wave Source Carrier Medium Wave Speed Radar Electromagnetic Wave (4-30 GHz) Not needed (able to propagate in empty / vacuum space) Speed of Light (300,000 km/s) Ultrasonic Mechanical Wave (> 20 kHz) Needed (air, liquid, solid) Speed of sound (344 m/s) Free WaveFree Wave Ultrasonic Radar Guided Wave Guided Radar Level Measurement 2. Position of Surface : Wave Type Advantages 1. Able to measure the level without making physical contact with process material 2. Unaffected by changes in the composition, density, moisture content, electrical conductivity, and dielectric constant of the process fluid Ultrasonic Radar Guided Radar Limitation 1. May not be used if vapour space of the material is dusty, or it contains foam, water vapour, or mists 2. Not applicable should the material has sound-absorbing surface (fluffy solids) 3. Reliable performance for difficult slurry or sludge-type services 3. Require a consistent temperature, since it is affected the speed of sound 1. Able to measure the level without making physical contact with process material 1. Not applicable for low-dielectric material that absorb the microwave 2. Unaffected by changes in the composition, density, moisture content of the process fluid 3. Changing vapour and foam has less effect than on ultrasonic type 4. Reliable performance for applications of medium difficulty, such as fuming acids, asphalt, LNG, tars, and other heavy hydrocarbons 1. Able to measure liquid interface level (with some conditions related with dielectric constant of the material & no emulsion layer) 1. Not applicable for low-dielectric material that absorb the microwave Level Measurement 2. Position of Surface : Electrical Properties Capacitive • • • • • Measures the changing electrical capacitance Applicable for both conductive and nonconductive fluids Provide both continuous and point measurement The dielectric constant of the fluid must remain constant Can not measure liquid interface Conductive • • • • Electric current flows through the fluid, container wall and the probe which actuates a relay Applicable for conductive fluids only Provide only point measurement Can provide differential level control (three-probetype) Level Measurement 2. Position of Surface : Nuclear Radiation • A radioactive source radiates through the vessel. The gamma quantum is seen by the radiation detector (such as a Geiger counter) and is transformed into a signal • Unaffected by temperature, pressure, and corrosion • Applied where other types of measurement cannot be used Level Measurement 2. Position of Surface : Mechanical Contact Tuning Fork (Vibration) • • • Keeping the probe vibrate in its natural frequency Relay triggered when process material in the tank reaches the vibrating elements and damps out the vibration Applicable for both liquid and solid material Rotating Paddle Switch • • • Small synchronized motor keeps the paddle in motion at very low speed When level raised to the paddle, it is stopped Applicable for solid material Float • • Applicable for liquid material Applicable for both point and continuous measurement Level Measurement 3. Load Cells The strain gauge (either foil or semiconductor) measures the stress which is introduced into a metal element, both compression & tension A bending beam type design uses strain gauges to monitor the stress in the sensing element when subjected to a bending force. Level Measurement 3. Load Cells Type Type Explanation Designed to operate in compression only Compression (Canister) Load can be applied at one end only, for some types it can be compressed by force at both ends Shear Beam Fixed rigidly at one end with the force being applied to the other end Bending Beam It consists of a straight beam attached to a base at one end and loaded at the other. Its shape can be that of a cantilever beam, a binocular design, an S-shaped or a ring design . Ring Torsion Round and flat bending beam sensors consisting of bonded foil strain gages encapsulated in a housing Helical The operation of a helical load cell is based on that of a spring. A spring balances a load force by its own torsion moment Picture Level Measurement 3. Load Cells Comparison Table Level Measurement Level Sensor Comparison Table Level Measurement Level Sensor Comparison Table (cont’d) Building Blocks: Measurement & Action I. Monitoring & measurement 1. Process Instrumentation • • • • • Flow Measurement Level Measurement Temperature Measurement Pressure Measurement Analytical Measurement 2. Packing Line Sensors II. Action 1. Process Instrumentation 2. Packing Line Actuators III. Hardware Selection : Which to Pick Temperature Measurement 1. Voltage Thermocouples 2. Resistance RTD Thermistor 3. Radiation Pyrometer (Infra Red) Optical Ratio / Two-Color Broadband (Total) Radiation 4. Material Expansion Liquid-in-glass Bimetallic Filled system Temperature Measurement 1. Thermocouples A thermocouple consists of two dissimilar metals, joined together at one end. When the junction of the two metals is heated or cooled a voltage is produced that can be correlated back to the temperature. Temperature Measurement Thermocouples Type Wire Material Range (in °C) Type Scale Linearity Positive Negative B Pt 70% Rh 30% Pt 94% Rh 6% E Chromel J Min Max Atmosphere Environment Recommended Favorable Points Less Favorable Points Good at high temps. Poor below 535 °C Inert or Slow Oxidizing 982 Good Oxidizing Highest mV/°C Larger drift than other base metal couples 0 816 Good; nearly linear from 150°C to 425°C Reducing Most economical Becomes brittle below 0°C -184 1260 Good; most linear of all TCs Oxidizing Most Linear More expensive than T or J Platinum 0 1649 Good at high temps. Poor below 535 °C Oxidizing Small size, fast response More expensive than K Pt 90% Rh 10% Platinum 0 1760 Good at high temps. Poor below 535 °C Oxidizing Small size, fast response More expensive than K T Copper Constantan -184 399 Good but crowded at low end Oxidizing or reducing Good reststance to corrosion from moisture Limited temperature Y Iron Constantan -129 982 Good; nearly linear from 150°C to 425°C Reducing 0 1860 Constantan -184 Iron Constantan K Chromel Alumel R Pt 87% Rh 13% S Not Industrial Standard Temperature Measurement 2. RTD (Resistance Temperature Detector) Measure temperature by correlating the resistance of the RTD element with temperature. The RTD element is made from a pure material whose resistance at various temperatures has been documented. It has a predictable change in resistance as the temperature changes RTD element construction type Wire-Wound • • Winding the wire on a glass or ceramic bobbin and sealing with molten glass Limited by strain induced at higher temperature Coil Elements • • • Threading a wire helix through a ceramic cylinder Allows the wire coil to expand more freely over temperature Not suited for extreme vibration Thin Film • • Depositing a thin film on a ceramic substrate Small, fast, inexpensive, less stable Temperature Measurement RTD Detector Type Metal Range (in °C) Min Platinum Nickel -200 -196 Max 850 Ice Point Resistance Characteristic Thin Film Type : 100, 1000 Ω Most Linear Wire-wound Type : 100, 200, 500 Ω Widely used 120, 500, 1000 Ω Not linear 316 Strain-sensitive Highest Temperature coefficient Copper -196 120 Used in electrical machinery due to very low reactance 10, 100 Ω RTD Wiring configuration 2-wire • • • Poor Accuracy No compensation for resistance of the connecting wires Transmitter must be placed very near with the sensor 3-wire • • Better accuracy than 2-wire Two leads to the sensor are on adjoining arms, therefore the lead resistance is cancelled out 4-wire • • Best accuracy Another pair of wires to form an additional loop that cancels out the lead resistance Temperature Measurement Thermocouples Vs RTD Characteristic Thermocouple RTD Measurement Range Wide Narrow Response Time Fast Slow Less Linear More Linear Cheap Expensive Accuracy Less Accurate More Accurate Sensitivity Less sensitive More Sensitive Repeatability Fair Excellence Long-Term Stability Fair Good Self Heating Effect Medium N/A Fair Excellent Medium High Linearity Price Point (end) sensitive Lead Effect Temperature Measurement 3. Optical The most basic design consists of a lens to focus the infrared (IR) energy on to a detector, which converts the energy to an electrical signal that can be displayed in units of temperature after being compensated for ambient temperature variation. Infrared pyrometers allow users to measure temperature in applications where conventional sensors cannot be employed. Specifically, in cases dealing with moving objects ( i.e., rollers, moving machinery, or a conveyor belt), Temperature Measurement Temperature Sensor Comparison Table Building Blocks: Measurement & Action I. Monitoring & measurement 1. Process Instrumentation • • • • • Flow Measurement Level Measurement Temperature Measurement Pressure Measurement Analytical Measurement 2. Packing Line Sensors II. Action 1. Process Instrumentation 2. Packing Line Actuators III. Hardware Selection : Which to Pick Pressure Measurement 1. Elastic Pressure Chamber (Mechanical) Bourdon Tubes Diaphragm Bellows 2. Electronics Capacitive Strain Gauge (Piezoresistive) Piezoelectric Inductive 3. Liquid Level Column Manometer Pressure Measurement 1. Mechanical Bourdon Bellows A bent oval tube. One end of the tube is linked to the process pressure, and the other end is sealed and linked to the mechanism operating the Pointer Shapes : C, Spiral, Helical One-piece axially expandable and collapsible element. Consists of many folds Diaphragm Converts the increasing process pressure on one side of the disk into a mechanical movement by monitoring the bulging of the disk Pressure Measurement 2. Electronics A typical electronics pressure transmitter consists of two parts: 1. Primary element Converts the pressure into an displacement / torque / mechanical value to be read by the secondary value. It may be diaphragm, bellows, etc 2. Secondary element The electronics that output from the primary element to a readable signal. It may be strain gauges, capacitive, piezoelectric, etc Pressure Primary Mechanical Element - Displacement - Torque Secondary Element Electric - Resistance - Capacitance - Voltage - Current Pressure Measurement 2. Electronics Strain Gauges / Piezoresistive Piezoresistive material changes its resistance when strain is applied Capacitive dP ceramic cell ceramic membrane ceramic body process pressure capacitor plates C1 C2 fill fluid The inlet pressure activates a diaphragm that is mounted between two fixed plates. This causes a capacitance change additional temperature sensor for permanent self monitoring Pressure Measurement 2. Electronics Inductive The inlet pressure activates a diaphragm / bellows moves a magnetic core inside the transformer. It creates an imbalance that is measured in the electronics Piezoelectric The inlet pressure activates a diaphragm / bellows that applies strain on a crystal (e.g., quartz). The strained quartz produces an electrical charge that is measured by the electronics Pressure Measurement Pressure Measurement Reference Absolute 1. Gage pressure Reference : Atmospheric pressure 2. Absolute pressure Reference : Complete vacuum Level 3. Differential pressure Difference between two pressure levels Gauge Pressure (psig, bar) DP Atmospheric Pressure Vacuum Pressure (-psig, -bar) Absolute Pressure (psia, bara) Absolute Zero Pressure Gauge Pressure Measurement Pressure Sensor Comparison Table Building Blocks: Measurement & Action I. Monitoring & measurement 1. Process Instrumentation • • • • • Flow Measurement Level Measurement Temperature Measurement Pressure Measurement Analytical Measurement 2. Packing Line Sensors II. Action 1. Process Instrumentation 2. Packing Line Actuators III. Hardware Selection : Which to Pick Analytical Measurement pH Conductivity Gas Detector MC Meter Chlorine Meter Turbidity Building Blocks: Measurement & Action I. Monitoring & measurement 1. Process Instrumentation • • • • • Flow Measurement Level Measurement Temperature Measurement Pressure Measurement Analytical Measurement 2. Packing Line Sensors II. Action 1. Process Instrumentation 2. Packing Line Actuators III. Hardware Selection : Which to Pick Measurement Position Position and distance sensors detect the presence or not of items on the move. This can be used to identify when an item arrives, count how many items have passed or when an item has left. Position technologies include photoelectric, laser, mechanical switches, proximity switches and pressure sensors. Measurement Colour Colour sensors can detect the presence or not of a successful operation. Has the label been printed, has the bottle got the right fluid in it, did the shrink wrap go on successfully Measurement Machine Vision Machine vision is successfully applied to many industrial inspection problems, leading to faster and more accurate quality control. Machine Vision allows the manufacturing industry to Detect Defects Calibrate and control the manufacturing process Optimise the use of resources Building Blocks: Measurement & Action I. Monitoring & measurement 1. Process Instrumentation • • • • • Flow Measurement Level Measurement Temperature Measurement Pressure Measurement Analytical Measurement 2. Packing Line Sensors II. Action 1. Process Instrumentation 2. Packing Line Actuators III. Hardware Selection : Which to Pick Action Valves Solenoid Valves Switching a pneumatic air supply to a valve or piston cylinder Modulating / Control Valves • Achieving precise control of a process fluid • Usually connected to I/P transducer that convert electrical signal into pressure signal Discrete Valves • Switching feeds on and off or, when used in conjunction with other valves, to select routes through pipework systems • It is usually connected to solenoid valve that switch on/off the air supply Action Motors Motors allow us to move things around whether it’s a pump moving liquids or a conveyor line moving boxes. Motor operation (start/stop) is usually controlled in the MCC (Motor Control Center). The control circuit in MCC usually consists of contactors & relays. Variable Speed Drives (VSD / Inverter) connected to the motor allows the motor speed to be controlled. Building Blocks: Measurement & Action I. Monitoring & measurement 1. Process Instrumentation • • • • • Flow Measurement Level Measurement Temperature Measurement Pressure Measurement Analytical Measurement 2. Packing Line Sensors II. Action 1. Process Instrumentation 2. Packing Line Actuators III. Hardware Selection : Which to Pick Action Solenoid Valves Switching a pneumatic air supply to a valve or piston cylinder Motors Stepper motors give precise control of movement. Servo drive motors allow added control functionality (ramp up, ramp down, torque) and faster positioning. Action Equipment Remote device interfaces allow us to control and “talk” with an enormous range of equipment and devices. This can take the form of a simple on/off control or a complex data/control interface. Action Mechatronics Building Blocks: Measurement & Action I. Monitoring & measurement 1. Process Instrumentation • • • • • Flow Measurement Level Measurement Temperature Measurement Pressure Measurement Analytical Measurement 2. Packing Line Sensors II. Action 1. Process Instrumentation 2. Packing Line Actuators III. Hardware Selection : Which to Pick Which to Pick Environment & System What are the the parameters the device will be exposed to and expected to perform in during both routine and exceptional circumstances? What are the performance criteria: speed, size, pass/fail criteria for the line? With which chemicals and under what conditions will the device be expected to operate? What hazards will be present and does this impact on the choice of device? What’s the commercial impact? Cost v benefit. Which to Pick ANSI/ISA 60529 Degrees of Protection Provided By Enclosures IP XX Protection against solid objects Protection against water Which to Pick ATEX DIRECTIVES Minimise, or completely eliminate, the risk of ignition in explosive areas and to limit the harmful effects in case of an explosion. Which to Pick ATEX DIRECTIVES