Specification

advertisement

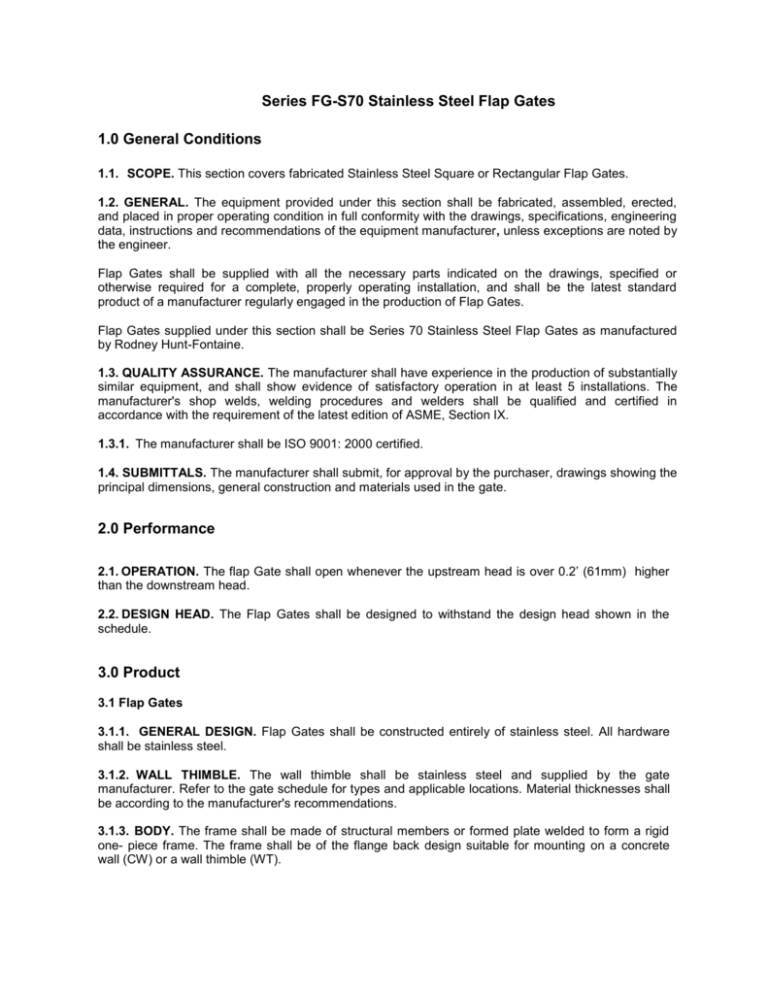

Series FG-S70 Stainless Steel Flap Gates 1.0 General Conditions 1.1. SCOPE. This section covers fabricated Stainless Steel Square or Rectangular Flap Gates. 1.2. GENERAL. The equipment provided under this section shall be fabricated, assembled, erected, and placed in proper operating condition in full conformity with the drawings, specifications, engineering data, instructions and recommendations of the equipment manufacturer, unless exceptions are noted by the engineer. Flap Gates shall be supplied with all the necessary parts indicated on the drawings, specified or otherwise required for a complete, properly operating installation, and shall be the latest standard product of a manufacturer regularly engaged in the production of Flap Gates. Flap Gates supplied under this section shall be Series 70 Stainless Steel Flap Gates as manufactured by Rodney Hunt-Fontaine. 1.3. QUALITY ASSURANCE. The manufacturer shall have experience in the production of substantially similar equipment, and shall show evidence of satisfactory operation in at least 5 installations. The manufacturer's shop welds, welding procedures and welders shall be qualified and certified in accordance with the requirement of the latest edition of ASME, Section IX. 1.3.1. The manufacturer shall be ISO 9001: 2000 certified. 1.4. SUBMITTALS. The manufacturer shall submit, for approval by the purchaser, drawings showing the principal dimensions, general construction and materials used in the gate. 2.0 Performance 2.1. OPERATION. The flap Gate shall open whenever the upstream head is over 0.2’ (61mm) higher than the downstream head. 2.2. DESIGN HEAD. The Flap Gates shall be designed to withstand the design head shown in the schedule. 3.0 Product 3.1 Flap Gates 3.1.1. GENERAL DESIGN. Flap Gates shall be constructed entirely of stainless steel. All hardware shall be stainless steel. 3.1.2. WALL THIMBLE. The wall thimble shall be stainless steel and supplied by the gate manufacturer. Refer to the gate schedule for types and applicable locations. Material thicknesses shall be according to the manufacturer's recommendations. 3.1.3. BODY. The frame shall be made of structural members or formed plate welded to form a rigid one- piece frame. The frame shall be of the flange back design suitable for mounting on a concrete wall (CW) or a wall thimble (WT). 3.1.4. COVER. The gate cover shall be made of structural members or formed plate adequately reinforced to withstand the maximum specified seating head without distortion. 3.1.5. SEALS. Seals shall be made of EPDM attached to the body by means of a flat stainless steel strip bolted to the frame. 3.1.6. HINGES. Hinges shall consist of a stainless steel pin and shall have a UHMWPE bushing. 3.1.7. HINGE ARMS. Hinge arms shall be made of structural members or formed plates. Gates 30" (762 mm) and over in diameter shall have a 2-hinge arm arrangement, with 2 pivot joints per arm, an adjustable lower pivot with limited rotation and an adjustable upper hinge lug arrangement to permit adjustment of the gate opening sensitivity to unseating head 4.0 Materials Part Material Body, cover, hinges, hinge arm Stainless steel ASTM A-240 Type 304L or 316L Hinge bushing Ultra high molecular weight polyethylene (UHMWPE) ASTM D-4020 Seal EPDM ASTM D-2000 Fasteners ASTM F593 and F594 GR1 for Type 304 and GR2 for Type 316 5.0 Execution 5.1. INSTALLATION. Gates and appurtenances shall be handled and installed in accordance with the manufacturer's recommendations.