Microbial Detection Arrays - University of Colorado at Boulder

advertisement

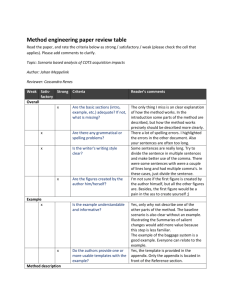

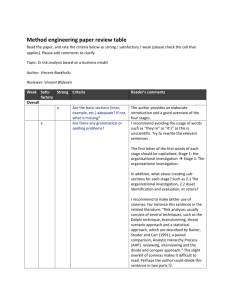

Microbial Detection Arrays October 23rd, 2006 Aerospace Senior Projects University of Colorado - Boulder 1 Team Members • • • • • • • • Elizabeth Newton – Project Manager Shayla Stewart – Systems Engineer Steven To – Chief Financial Officer Dave Miller – Fabrication Engineer Ted Schumacher – Lead Thermal Engineer Jeff Childers – Lead Structural Engineer Charles Vaughan – Lead Electrical Engineer Sameera Wijesinghe - Webmaster 2 Briefing Overview Jump to • • • • • • • • • Overall Objectives System Design Alternatives Design-To Specifications Thermal Design Options Structural Design Options Electrical Design Options Project Feasibility and Risk Project Plan Appendices Look for me for further info 3 Overall Objectives 4 Picture from www.physics.byu.edu Objectives Overview • Objective: To design and build a field-ready unit capable of providing a testing environment for electrochemical sensors to detect microbial life by soil analysis • Deliverables: – Field-ready unit – Test data verifying requirements – Operational manual for use Electrochemical sensors • Sensors developed by Tufts University and BioServe – Sensors analyze soil for metabolic indicators such as pH and chemical composition and convert them to electronic signals – Assumes that life only needs water and nutrients found in native soil to metabolize 5 Functional Diagram Geological Sample • • Soil Sterilization • • Inoculation Sample Temperature Control Power • Reagent Water Sensors Test Chamber • Control Chamber Mixer Mixer Temperature Control Temperature Control Data Acquisition and Control • Accept soil Sterilize soil using an autoclave Add reagent water Move soil to reaction chambers Add non-sterile inoculation sample to test chamber Mix soil and water while starting temperature control Testing lasts for two weeks 6 Functional Requirements • Must be capable of performing in extreme Earth conditions – McMurdo Bay, Antarctica -10°C to 2°C (during summer) – Atacama Valley, Chile -6°C to 38°C Pictures from Wikipedia.org • Must provide and function with power comparable to next-generation Mars science rovers (30 Watts) • Must be portable (30 kg) 7 Assessment of System Design Alternatives Pro of cost, mass, and volume • Quantitative analysis -Reaction chambers at same temperature based on rough estimates -No need to heat/cool each chamber individually Con • Ultimately, complexity -No waybecame to correct if primary one chamberconsideration is warmer than the Environmental Controls Sterilization Chamber other Pro -More volume to heat/cool Shared -No need for extra environmental chamber Con -Each reaction chamber must be heated/insulated Pro Separate Overall Architecture: -Only one chamber must be fabricated -Only needs one heater •Shared Environment Con •Separate Sterilization -Soil must be separated into test/control chambers after Chambers sterilization Shared Pro -No need for soil separation: reduced complexity Con -Two chambers and two heaters Separate 8 System Design Alternatives End Result • Separate Autoclaves • Shared Environment 9 Design-To Specifications • Thermal Subsystem – Mass: 16.3 kg – Volume: 0.096 m3 – Cost: $660 • Structural Subsystem (excluding chassis) – Mass: 11.3 kg – Volume: 0.00293 m3 – Cost: $280 • Electrical Subsystem (excluding power supply) – Mass:0.30 kg – Volume:0.00045 m3 – Cost:$1340 • Overall System – Mass:27.9 kg – Volume:0.09938 m3 – Cost:$2280 • Total Funds: $8000 10 Overall System Architecture Autoclaves Water Chamber Pump Inoculation Chamber Test Chambers DAQ/Power TEC 11 Work Breakdown Structure MiDAs Thermal Subsystem Structural Subsystem Electrical Subsystem Thermal Control Materials Power Insulation Soil/Water Transport Data Acquisition Mixing Sensors 12 Thermal Design Options Pictures from melcor.com, minco.com, wikipedia.org, energysolutionscenter.org 13 Insulation Options • Insulation applications – Autoclave chambers – Environmental chambers – Reagent water chamber – Inoculation sample chamber • Insulation Requirements – Minimize power needed to heat chambers – Protect electrochemical sensors from heaters • Criteria (order of importance) 1. Volume (thermal conductivity, k) 2. Complexity 3. Cost 14 Insulation Option Pros and Cons Pros Silica Aerogel Thermal Coat Ceramic Cons -Very low thermal conductivity -Expensive -Moisture resistant -Adds almost no volume because it is painted on -Complicated application Fiber Board (Sindayno) -Very low density -350 -Thermal conductivity is higher than that of air Additional Options for Heating and Cooling 15 Structural Design Options 16 Pictures from trendir.com, polypenco.co.jp, sonozap.com, sciencelab.com, parker.com Material Options • Material applications – Autoclave chambers • Must be able to withstand high temperatures and pressures • Must be corrosion-resistant – Environmental, inoculation, and reagent water chambers • Need to be lightweight – Reaction chamber • Must be able to be sterilized • Must be inert • Criteria (order of importance) 1. Mass 2. Complexity (machineability) 3. Cost 17 Material Pros and Cons Pros Cons -Low density -High yield strength -Easy to machine -Could not withstand contact with heating elements -Somewhat expensive 316 Stainless Steel -High strength -Very high melting temperature -Relatively inexpensive -High density Ultem 1000 -Low density -High yield strength -Easy to machine -Relatively inexpensive -Could not withstand contact with heating elements Polysulfone Additional Options for Soil/Water Transportation and Mixing 18 Electrical Design Options Pictures from spectrolab.com, fuelcellstore.com, dpie.com, weedinstrument.com 19 Power Supply Options • Power supply requirements – Power supply must provide 30 W of power – Must power the MiDAs instrument for duration of experiment (17 days) • Criteria (order of importance) – Cost – Mass – Volume 20 Power Supply Pros and Cons Pros Cons -Very high energy density -Safety and logistic issues -Switching out tanks -Expensive -High energy density -Less complex -Very large and heavy -Requires a recharge system Lithium Ion Battery -Very high energy density -High demand -Requires a recharge system -Problems holding charge with age Dual Junction Solar Cells -Safe, relatively simple -Can be used to recharge batteries -Requires sunshine Fuel Cell Sealed Lead Acid Battery Additional Options for Data Acquisition and Pressure/Temperature Sensors 21 Feasibility and Risk Picture from http://www4.macnn.com/games/gamecenter/risk2/s_01_lrg.jpg 22 Project Risk Assessment Mitigation Factors X Material X Soil Handling X X X X X X Power Supply X Data Acquisition X Sensors X Green Subsystems= Low Risk X X X X X X Mixing High Power Use Insulation Hard to Obtain Thermal Control Difficult Analysis Expensive Lack of Expertise Easy to Machine Simple Easy to Obtain Inexpensive Lots of Options Subsystem Risk Factors X X X X X X X X X X Yellow Subsystems = Medium Risk Red Subsystems= High Risk23 Autoclave Feasibility Assumptions – Fluid inside is only water (high specific heat of water will give maximum boundary) – Insulation radius = 10 cm of material (thermal conductance of k = 0.012 W/m °C) – Internal and external losses and safety margin = 2.4W (20% of heating/cooling capacity) – Specific heat (Cp) for 316 steel = 452 J/kg K – Specific heat (Cp) for water = 4230 J/kg K – Heater uses 12 W per chamber – Standard autoclave techniques implies • 121°C, hold for 15 min • Cool to 20°C, hold for 24 hours • Repeat 3 times 24 Autoclave Feasibility Analysis h2 25 W m 2C Rconduction = Thickness kA Rconvection 1 0.427 C W h2 Aoutside = 79.8 C/W Rtotal Rconduction Rconvection 79.82 C Q Tinside Tsurroundings Rtotal 1.64 W U sys U steel U water Q W • Time to heat from -10°C to 121°C = 3.9 hours • Time to cool to 20°C = 117 min with active cooling • Power: – 3.9 amp hours to heat – 0.04 amp hours to hold for 15 minutes – 1.95 amp hours to cool – 3.36 amp hours to hold for 24 hours Q [( m)(c p )(T2 T1 )] steel [( m)(c p )(T2 T1 )] water 25 Autoclave Solution and Verification • Solution: – Sterilization chamber mock-ups will be made and tested with various heaters and insulation to verify that it is possible to achieve 121°C • Verification: – Temperature and pressure sensors will be used to verify that a sand/water solution can reach 121°C on 30 W of power 26 Autoclave Power Summary Power Summary (Sterilization Phase) 30 25 Autoclave Heater/Cooler 1 Autoclave Heater/Cooler 2 DAq Temp/Pressure Sensors Total Power 20 15 10 5 18 00 15 00 12 00 90 0 60 0 30 0 0 0 Power Consumption (W) 35 Operation Time (min) 27 Mixing Feasibility Analysis • Requirement: – Soil and water must be mixed within the reaction chambers • Reduces boundary layer so electrochemical sensors can read correctly • Prevents soil sedimentation • Problem: – Difficult to find mixers small enough to fit in reaction chambers – Flow pattern difficult to analyze without testing – Unknown if ultrasonic mixers can be used at appropriate frequency – Magnetic stirrers may affect electrochemical sensors 28 Mixing Solution and Verification • Solution: – Mock-ups of reaction chambers will be prototyped and tested with various mixers – Different soil granularities will be tested – Various mixing regimes will be tested • Continuous mixing • Pulsed mixing • Verification: – Flow patterns and soil sedimentation will be visually analyzed to show that various types of mixing regimes and mixers provide adequate stirring 29 Project Plan Picture from http://www.connectedconcepts.net/clip%20art/Project%20Plan.gif 30 Organizational Chart Project Manager Elizabeth Newton Chief Financial Officer Steven To Systems Engineer Shayla Stewart Safety Engineer Chuck Vaughan Thermal Subsystem Electrical Subsystem Structural Subsystem Thermal Lead Ted Schumacher Electrical Lead Chuck Vaughan Structures Lead Jeff Childers Dave Miller Steven To Elizabeth Newton Jeff Childers Sameera Wijesinghe Sameera Wijesinghe Fabrication Engineer Dave Miller Shayla Stewart 31 Schedule Through CDR 32 Schedule Through CDR 33 Schedule Past CDR • Machining: – Assume one chamber machined per week – Last Machining Day – March 16, 2007 • Testing: – Subsystem testing can begin as soon as each chamber is constructed – Overall testing: March 16, 2007 – April 17, 2007 • Final Review – April 17, 2007 • ITLL Expo – April 28, 2007 • Final Report – May 3, 2007 34 Conclusions • Project is feasible – Budget is one-quarter of funds – Mass is 34 kg, which is portable – Initial calculations and research indicate that high risk subsystems (mixing and autoclaving) are challenging but possible • Further analysis through prototyping will be performed before CDR – System is capable of performing in specified environments – System is capable of performing with 30 W of power – Many options are available to meet each requirement • This allows off-ramps in case some options are dismissed during design 35 Questions/Comments? Picture from http://content.answers.com/main/content/wp/en/thumb/5/5b/250px-Nasa_mer_marvin.jpg36 References 1. Cengel, Yunus. Introduction to Thermodynamics and Heat Transfer. McGraw-Hill. University of Nevada, Reno. 1997 2. Gilmore, David. Spacecraft Thermal Control Handbook. Aerospace press. El Segundo, California. 2002 3. www.aerogel.com 4. www.dimondsystems.com 5. www.matweb.com 6. www.mcmaster.com 7. www.melcor.com 8. www.minco.com 9. www.omega.com 37 Appendix Table of Contents • • • • • • System Architecture Options Chamber Geometries Verification Methods Power Model and Budgets Operational Environment Subsystem Options, Trade Studies, and Pros and Cons 38 Appendix A: System Parameter Estimates Mass (g) Volume (mL) Cost Reaction Chamber 127 100 $11 Large Autoclave Chamber 4013.5 500 $125 Small Autoclave Chamber 2006.75 250 $63 Soil Transport 88 100 $2.60 Motor 150 200 $20 Moving Sensor Package 254 200 $22 Environmental Sensors 10 50 $200 39 Assessment of System Design Alternatives Quantitative Analysis of Options Mass (g) Volume (mL) Cost Shared Environment, Shared Sterilization 900 4444 $150 Separate Environment, Shared Sterilization 1200 4504 $1,350 Separate Environment, Separate Sterilization 1400 4612 $1,750 Shared Sterilization, Separate Environment 1300 4592 $1,350 Mass, volume, and cost figures do not include components that all options need the same number of, such as a reagent water tank and mixers. 40 Option A • Sterilization and testing occur in same chamber • Requires: – 1 large autoclave – 2 moving sensor packages – 2 motors – 2 environmental sensors Mass: 1000 g Volume: 4842 mL Cost: $600 • High complexity from moving sensor packages 41 Option B • Shared sterilization, separate environment • Requires: – 1 large autoclave – 2 reaction chambers – 2 soil transport tubes Mass: 900 g Volume: 4444 mL Cost: $150 42 Option C • Shared sterilization, separate environment • Requires: – 1 large autoclave – 2 reaction chambers – 2 soil transport tubes – 6 environmental sensors 43 Mass: 1200 g Volume: 4504 mL Cost: $1350 Option D • Separate sterilization, separate environment • Requires: – 2 small autoclaves – 2 reaction chambers – 3 soil transport tubes – 8 environmental sensors Mass: 1400 g Volume: 4612 mL Cost: $1750 44 Option E • Separate sterilization, shared environment • Requires: – 2 small autoclaves – 2 reaction chambers – 3 soil transport tubes – 6 environmental sensors 45 Mass: 1300 g Volume: 4592 mL Cost: $1350 Autoclave Chamber Geometry • Assumptions of a possible design: – Chamber is made of 316 stainless steel – 5 mL water added to chamber for use in autoclaving – 15 mL space provided so sample is not tightly packed – Chamber is a cylinder • Dimensions: – Total internal volume of chamber = 45 mL – Internal diameter = 2.54 cm – External diameter = 3.04 cm – Wall thickness = 0.25 cm – Length = 9.38 cm – Mass = 0.19 km 46 Reaction Chamber Geometry • Assume: – Chamber is made of Ultem 1000 – Chamber wall thickness of 0.5 cm – Inside chamber geometry is a cylinder – 20 mL additional space for mixing (70 mL total volume) • Dimensions: – Walls: 0.5 cm thick – Outside diameter = 3.95 cm – Height = 11.28 cm – Mass = 0.0866 kg Drawings by Jake Freeman 47 Environmental Chamber Geometry Top View Side View • Assume: – Chamber is a cube containing both reaction chambers – Buffer around chambers is 3 cm with 2 cm between them • Dimensions: – Height: 17.28 cm – Depth: 9.95 cm – Width: 11.95 cm – Volume: 2054.635 cm3 48 Reagent Water Chamber Geometry Side view • Assume: – Chamber is a cylinder – Water expands upon freezing • Dimensions: – Height: 2.1 cm – Radius: 3.0 cm – Volume: 60 cm3 49 Verification Methods Requirement # Title Verification Method PDD 4.1 Reaction Chamber Volume I, D Verification will be through simple volume measurement. PDD 4.2 Reaction Chamber Temperature A, T Verification will be through thermal analysis of the reaction chamber geometry and test by means of simple temperature sensors. PDD 4.3 Reaction Chamber Pressure A, T Verification will be through thermal analysis of the reaction chamber geometry and test by means of simple pressure sensors. PDD 4.4 Reaction Chamber Sensor Capability A, I Verification will be through analysis of the chamber geometry and by visual means. A, I Verification will be through analysis of the flow pattern generated during mixing and basic prototype inspection testing. Verification PDD 4.5 Reaction Chamber Mixing Capability PDD 4.6 Reaction Chamber MultiUse Port A, I PDD 4.7 Reaction Chamber Material A Verification will be through structural and thermal analysis of the reaction chambers. PDD 4.8 Geological Sample Volume T Verification will be through measuring soil before it is added to the autoclave chambers PDD 4.9 Inoculation Sample Volume T Verification will be through measuring inoculation sample before it is added to the inoculation sample chamber PDD 4.10 Inoculation Sample Reception A, D Verification will be through analysis of the chamber geometry and by visual means. Verification will be through analysis of soil transport and demonstration to show sample delivery. 50 Verification Methods Requirement # Title Verification Method PDD 4.11 Reaction Sample Handling A, T Verification will be through thermal analysis of the autoclave chambers and testing by means of temperature and pressure sensors. PDD 4.12 Inoculation Sample Handling A, T Verification will be through thermal analysis and testing by means of temperature sensors. PDD 4.13 Reaction Sample Delivery A, D Verification will be through analysis of soil transport and demonstration to show sample delivery. PDD 4.14 Inoculation Sample Sterility A, D Verification will be through analysis of soil transport and demonstration to show sample delivery. PDD 4.15 Reagent Water Containment A, T Verification will be through thermal analysis and test by means of temperature sensors. PDD 4.16 Reagent Water Delivery A, D Verification will be through analysis of soil transport and demonstration to show sample delivery. PDD 4.17 Reagent Water Temperature A, T Verification will be through thermal analysis and test by means of temperature sensors. PDD 4.18 Sensor Integration A, I Verification will be through analysis of the reaction chamber geometry and simple volume measurement. PDD 4.19 Sensor Data Collection Rate A, T Verification will be through analysis and testing of the command software. PDD 4.20 Sensor Data Acquisition A, T Verification will be through analysis and testing of the command 51 software. Verification Verification Methods Requirement # Title Verification Method PDD 4.21 Sensor Data Accessibility D PDD 4.22 MiDAs Status Warnings A, T Verification will be through analysis and testing of the command software. PDD 4.23 MiDAs Command A, T Verification will be through analysis and testing of the command software. PDD 4.24 Field Power A, T Verification will be through analysis of the power supply and testing through standard electronics lab equipment. PDD 4.25 Laboratory Power D Verification will be through a demonstration of the instrument with the external laboratory power supply. PDD 4.26 Nominal Power Consumption A, T Verification will be through analysis of the power consumption of each component and testing. PDD 4.27 Peak Power Consumption A, T Verification will be through analysis of the power consumption of each component and testing. PDD 4.28 Unit Disassembly D Verification will be through a demonstration of the instrument disassembly. PDD 4.29 Operational Cycle D Verification will be through a demonstration of a complete operational cycle. PDD 4.30 Operational Environment A Verification will be through thermal analysis of the surrounding environment. Verification Verification will be through demonstration of data transfer. 52 Power Model Power Summary (Experiment) 25 Thermal 15 Structures Electronics 10 Total 5 96 0 10 80 12 00 13 20 14 40 15 60 16 80 18 00 19 20 84 0 72 0 60 0 48 0 36 0 24 0 0 0 12 0 Power Consumption (W) 20 Operation Time (min) 53 Mass Budget Autoclave (316 Steel) x 2 9 kg Test/control/water chamber (Ultem1000) x 3 2.13 kg Inoculation chamber (Ultem1000) 0.19 kg Autoclave Insulation (Aerogel) 13.4 kg Test/control Insulation (Aerogel) 2.9 kg DAQ 0.285 kg Sensors 0.125 kg Extra (Ultem1000 Chassis) 6 kg Power supply 4 to 30 kg Total (excluding power supply) 34 kg 54 Cost Budget Heaters x 4 $160 Autoclave (316 Steel) x 2 $240 Test/control/water chamber (Ultem1000) x 3 $40 Inoculation chamber (Ultem1000) Included above Autoclave Insulation (Aerogel) $500 (min purchase) Test/control Insulation (Aerogel) Included above DAQ $995 Sensors $345 Total $2280 Total Funds: $4000 from Senior Projects $4000 from BioServe Total: $8000 55 Operational Environment Laboratory McMurdo Bay, Antarctica (summer) Atacama Valley, Chile (Altitude = 2000 m) Temperature (max) 30°C 2°C 38°C Temperature (min) 20°C -10°C -6°C Pressure (avg) 1 atm 1 atm 0.802 atm 56 Thermal Control Design-To Requirements Requirement # PDD 4.2 PDD 4.11 PDD 4.15 PDD 4.17 PDD 4.30 Title Requirement Importance Reaction Chamber Temperature Each reaction chamber shall be controllable within a range of 4°C to 37°C with an accuracy of ±1°C. This environment is acceptable for the possible life to metabolize and reproduce. Reaction Sample Handling The reaction samples shall be sterilized in accordance with standard Autoclave techniques. This is the best method of sterilization for killing the known forms of life. Reagent Water Containment The sterile reagent water shall be completely contained in both solid and liquid form. This prevents the reagent water container from bursting if the water freezes. Reagent Water Temperature The reagent water shall be delivered to the reaction chambers at a temperature not to exceed 60°C. The electrochemical sensors can't withstand temperatures above 60°C. Operational Environment MiDAs shall be able to operate in environments ranging from Antarctica to Atacama Valley in Chile. These are the likely test sites for the MiDAs instrument. 57 Heating/Cooling Options • Heating applications – Autoclave chambers: must reach 121°C and hold for 15 minutes – Environmental chambers: must maintain temperatures from 4°C to 37°C for 14 days • Cooling applications – Autoclave chambers – must be cooled from 121°C to 20°C – Environmental chambers – must maintain temperatures from 4°C to 37°C for 14 days • Criteria 1. Volume 2. Power consumption 3. Risk 4. Complexity 5. Mass 6. Cost 58 Heating Option Pros and Cons Pros Strip Cons -Strong sheath -Difficult to find small sizes -Good at heating air -Custom length and resistance needed -Cheap -Easy to custom-order -Kapton coating -Clamping system required -Best used for conduction heating Immersion -Direct heating for substance -Heating element may get in the way of mixer Cartridge -High watt density -Requires tight tolerances for placement -Strong sheath -Small sizes don’t have high wattages Tubular Tape or flexible Band 59 Cooling Option Pros and Cons Pros Cons -Does not require power -Simple -Geometry of chambers may limit effectiveness -Longest cooling time Heat Switch -Allows most sides of chamber to be insulated while still allowing cooling -Complex implementation -Difficult to find data Thermoelectric Cooler -Concentrated cooling power -Allows most sides of chamber to be insulated while still allowing cooling -Requires power Passive 60 Heating Options Heating application Typical off the shelf example Power of example Overall Size of example (inches) Weight of example (lbs) Price of example Strip Gases or solid surfaces Omega PT512/120 2.5W at 12V 5.5 x 1 x 1.5 0.4 $30 Tubular Gases Omega TRI1212/120 3.3W at 12V 0.246 O.D.x 12 long 0.2 $28 Tape or flexible Solid surfaces or possibly gases Minco HK5464R4.9L1 2A 29.39W at 12V 3x3 0.01 $33.80 Immersion Liquids Omega RI100/120 2W at 12V Internal heating component = tube 1.5 long x 0.625 O.D. 3 $115 Cartridge Solids Omega CSS01235/120 0.7W at 12V 0.124 O.D. x 2 long 0.06 $26 Band Solids in cylindrical form Omega MBH1215200A /120 4W at 12V 1.25 I.D. x 1.5 width 0.87 $32 61 Cooling Options Typical off the shelf example Power of example Overall Size of example (inches) Weight of example (lbs) Price of example Passive Cooling NA 0 0 0 $0 Heat Switch Starsys Research Diaphragm Thin Plate Switch Thermoelectric Melcor CP1.0Cooling 127-05L-1-W5 May not be available at this time 16 W 30 mm x 30 mm x 3.2 mm 0.024 $15.54 62 Insulation Options Density (kg/m^3) Cost K (W/m-K) Silica Aerogel 5-200 $325 for 50 g + $30 shipping 0.016-0.03 TC- Ceramic Unknown Unknown 0.097 Fiber Board (Sindayno) -350 1900 Unknown 0.63 Air 1.168 NA 0.025 63 Material Design-To Requirements Requirement # Title Requirement PDD 4.7 Each reaction chamber shall be manufactured out of a list of materials Reaction provided by BioServe. Chamber This list includes, but is not Material yet limited to, Polysulfone, Pharmed, 316 stainless steel, and Ultem 1000. PDD 4.11 Reaction Sample Handling The reaction samples shall be sterilized in accordance with standard Autoclave techniques. Importance All of these materials are able to be autoclaved, have high resistance to corrosion, and are FDA approved for food service or medical use. This is the best method of sterilization for killing the known forms of life. 64 Material Options Density (g/cm3) Yield Strength (MPa) Maximum Temperature (°C) Cost per kg Machineability Polysulfone 1.24 74.9 149-180 $5.93 Very good 316 Stainless Steel 8.027 205 899 $2.32 Fair Ultem 1000 1.27 110 170 $3.84 Very good 65 Soil Handling Design-To Requirements Requirement # Title Requirement PDD 4.8 Geological Sample Volume Each reaction chamber shall receive no less than 5 mL and no more than 25 mL of geological sample. PDD 4.9 Inoculation Sample Volume The test chamber shall receive a maximum of 1 mL of inoculation sample. Importance 5 mL is the about the minimum amount of soil to obtain good results. 25 mL is still small enough amount to keep the experiment light and portable. The nonsterile inoculation sample is what could contain life. The test chamber shall receive the inoculation sample through established aseptic techniques. The user needs to know that any detected life forms were already present in the soil, not transferred to the soil through the transportation method. Reaction Sample Delivery One pre-measured reaction sample shall be delivered to the test chamber and one pre-measured reaction sample shall be delivered to the control chamber. Both samples shall maintain sterility throughout delivery. Having equal amounts of soil in each reaction chamber helps maintain uniformity between the test and control. Once the soil is sterilized, it has to remain sterile so that no life forms are introduced. Inoculation Sample Sterility The inoculation sample shall be aseptically delivered to the test chamber. The inoculation sample can't pick up any living organisms from the MiDAs instrument. If life is detected, one needs to know that it was originally in the soil or the experiment is useless. PDD 4.16 Reagent Water Delivery The MiDAs shall aseptically deliver no more than 50 mL (within ± 5% accuracy) of sterile reagent water to each reaction chamber. The delivery must be aseptic, so that no living organisms are transferred to the reagent water. PDD 4.28 Unit Disassembly MiDAs shall be able to be taken apart so that it may be sterilized and reassembled for multiple Earth tests. The instrument needs to be reusable. PDD 4.10 PDD 4.13 PDD 4.14 Inoculation Sample Reception 66 Soil/Water Transportation Options • Soil and water transportation includes pumps, tubing, and valves • Soil/water handling applications – Reagent water transferred to sterilization and inoculation chambers to flush soil – Soil and water mixture transferred from sterilization and inoculation chambers to reaction chambers • Criteria 1. Complexity (autonomy) 67 Soil/Water Transportation Pros and Cons Cons Sealing Gates Pros Push/Pull Solenoids -Simple -High reliability -Low cost -Small -Not variable Electromagnets -Simple -High reliability -Med cost -Small -High power usage Motor -Compatibility -Small -Low cost Pressure Sealing -High reliability -Two way -Complex setup -Less parts -Low reliability -Complex setup -One way -May have interference with sensors Magnetic Sealing -Complexity -Low reliability 68 Soil Transportation Options Gate Options Voltage Power Complexity Reliability Size Push/Pull Solenoids 3VDC 3W low high d = 25.5mm h = 28.9mm Electromagnets 12VDC ? low high d = 35mm h=~45mm Motor 12VDC 58 RPM low high d =6.3 mm Belt System N/A N/A high med custom Pressure Plug N/A N/A low high custom Push/Pull Solenoid 3VDC 3W low high d = 25.5mm h = 28.9mm High Torque Motor TBD TBD low high d = 127mm h = 127mm Belt System N/A N/A high med custom Electromagnets 12VDC ? high high very large High Compression Spring N/A N/A high low custom Motor System Sealing Options for Autoclave Pressure Sealing Magnetic Sealing 69 Mixing Design-To Requirements Requirement # PDD 4.5 PDD 4.28 Title Requirement Importance Reaction Chamber Mixing Capability Each reaction chamber shall have mixing capability such that each geological sample is evenly distributed within the fluid while movement is present at each sensor location. The fluid must be mixed so that the sensor readings are as accurate as possible. The fluid must also move at each sensor so that the boundary layer around the sensors is broken down, which is necessary to get a reading. Unit Disassembly MiDAs shall be able to be taken apart so that it may be sterilized and reassembled for multiple Earth tests. The instrument needs to be reusable. 70 Mixing Options • Mixing applications – Soil in reaction chambers must be stirred • Electrochemical sensors need fluid movement to function • Prevents sedimentation to soil • Criteria (order of importance) 1. Volume 2. Power usage 3. Risk 4. Cost 71 Mixing Option Pros and Cons Pros Cons Ultrasonic -BioServe may provide -Does not disrupt ISE’s -Ruptures cell membranes above 18 kHz -Expensive -Lack of prior experience Magnetic -No known machining required -Does not require probe through top or bottom of reaction chambers -ISE interference pending test -Magnetic Martian soil Mechanical -Known flow-pattern -Does not disrupt ISE’s -Common use / more experience -Soil could clog mechanism -Most COTS mixers are too large 72 Mixing Options Ultrasonics Volume Cost Power PCB: 5" x 2 3/4" x 1" $1295* variable Probe: 0.850" diam, 4 1/2" long Probe tip: 1/8" diam x 2" long Ti alloy Magnetic 4.8” x 4.8” x 1.8” Unknown Mechanical 0.8 mm diameter impeller Unknown 73 Power Supply Design-To Requirements Requirement # Title Requirement Importance Field Power MiDAs shall provide its own power (between 10 W and 30 W) in a field setting. MiDAs shall provide its own power (between 10 W and 30 W) in a field setting. PDD 4.25 Laboratory Power MiDAs shall be capable of receiving between 10 W and 30 W from an external power supply in a laboratory setting. The instrument needs to be capable of running in a lab, as well as the field. PDD 4.26 Nominal Power Consumption Nominal power consumption shall not exceed 30 W. This is based on estimates of the Mars astrobiology rover PDD 4.27 Peak Power Consumption Peak power consumption shall not exceed 30 W for more than 30 seconds. This is based on estimates of the Mars astrobiology rover Operational Cycle One operational testing cycle shall be 14 standard Earth days, not including power-up, sterilization, and powerdown. This is the time given for the potential life to reproduce and metabolize. PDD 4.24 PDD 4.29 74 Power Supply Options Mass (kg) Volume (cm3) Cost Power Provided Time for Delivery Fuel Cell 1.133 637 $1769 30W @ 12V 3-4 Weeks Sealed Lead Acid Battery 30 10577 $165 40 hrs, 30W @ 12 V 2-3 Weeks Lithium Ion Battery 8 4800 $40 30 W @ 12V 2-3 Weeks Dual Junction Solar Cells 0.118 kg (does not include backing) Area = 30 cm2 $940 (to charge) 30 W @ 12 V 2 Weeks 75 Data Acquisition Design-To Requirements Requirement # Title Requirement Importance Reaction Chamber Sensor Capability Each reaction chamber shall be capable of supporting no fewer than 6 and no more than 18 electrochemical sensors. This is the number of electrochemical sensors that will be provided by the customer. PDD 4.19 Sensor Data Collection Rate The electrochemical sensors shall have a data collection rate of 1 measurement per minute per sensor. Since the experiment takes place over 14 days, a reading each minute from each sensor is sufficient to characterize the experiment results. PDD 4.20 Sensor Data Acquisition All data taken through the sensors shall be collected and stored for analysis. The data will be analyzed after the experiment is completed. PDD 4.21 Sensor Data Accessibility The scientific and engineering status data shall be accessible to users throughout the experiment. The customer would like to be able to look at the status of the experiment while it is in progress. PDD 4.22 MiDAs Status Warnings MiDAs shall provide caution, warning, and instrument status to external ground support equipment. This is necessary to be able to observe the status of the instrument, as well as detect errors. PDD 4.23 MiDAs Command MiDAs shall receive commands from external ground support equipment. The duration of the experiment is such that it is not reasonable to have the user initiate each step of the process. Operational Cycle One operational testing cycle shall be 14 standard Earth days, not including power-up, sterilization, and powerdown. This is the time given for the potential life to reproduce and metabolize. PDD 4.4 PDD 4.29 76 Data Acquisition Options • Data acquisition applications: – Must be able to give commands to sensors, heaters, and soil transport – Must be able to store data with a collection rate of one sample per sensor per minute • Criteria: – Power usage – Cost 77 Data Acquisition Options DAQ Cards model power LabJack UE9 5 V or by USB cable $429 --- 75mm 185mm 30mm 16 bit --- 2 week shipping by USB cable $99 --- 75mm 115mm 30mm 12 bit --- 2 week shipping LabJack U3 price Weight Width Length Height Resolution Memory Time Embedded CPU with DAQ Athena 10 W $825 150 g 4.175" 4.45" --- 16 bit 128 MB 2 week shipping Poseidon 3.5 W $995 --- 4.528" 6.496" --- 16 bit 256 MB 2 week shipping Elektra 5.5 W $750 108 g 3.55" 3.775" --- 16 bit 128 MB 2 week shipping Hercules 12 W $500 285 g 8" 5.75" --- 16 bit 128 MB 2 week shipping 78 Data Acquisition Pros and Cons Pros Data Acquisition Card -Self powered (draws power from computer) -Embedded system -Can provided variety of data transfer options Embedded CPU w/ -Can be used to store data until Data Acquisition testing complete -Can provide accessibility to autonomous control Cons -Requires additional hardware -Requires additional power consumption -Expensive 79 Pressure and Temperature Sensor Options • Pressure and temperature sensor applications: – One of each sensor in the sterilization chambers capable of withstanding high temperature – One of each sensor in the each reaction chamber – One temperature sensor in the reagent water chamber • Criteria: – Cost – Power usage – Temperature range 80 Temperature Sensor Pros and Cons Pros Thermocouples Thermistors Resistance Temperature Detectors (RTD) Cons -Variety of types and configurations -Low cost, wide availability -Reliable -Self-powered -Can handle autoclave temperatures -Requires a cold junction compensator for calibration -Sensor accuracy can reach 1°C at temperatures between 10°C and 40°C -Better accuracy than thermocouples and RTDs -Loss of linearity -Requires shielding from high temperatures -Requires current -High accuracy -Excellent stability and reusability -Can be immune to electrical noise -Requires shielding from high temperatures -Requires current to take measurements 81 Temperature Sensor Options Thermocouples Volume Cost Weight Diameter Length Temp Range Operation Range Accuracy (1-40 °C) 5SRTC-TT (mini connector) $54 (5 pack) --- 0.51mm 1m T --- ±1 °C 2 day shipping available TJ36 (autoclave probe) $92 --- 1.6mm 1m JKTE --- --- 2 day shipping available $15 --- 2.8mm 60mm -80 to 250 °C --- ±1 °C 2 day shipping available Height Length Width 25mm 2m 19mm -73 to 260 °C --- ±0.5 °C 2 day shipping available Height Length Width Model Time Thermistor 44005 RTD SA1-RTD $50 --- CJC MCJ-T (battery included) $99 57 g 13mm 75mm 25mm T 10-45 °C --- 2 day shipping available CJ-T (battery included) $170 75 g 12mm 75mm 49mm T 10-50 °C --- 2 day shipping available 82 Pressure Sensor Pros and Cons Pros Gauge Absolute Differential Cons -Widely available -Relatively cheap -Measures pressure relative to standard atmosphere -Measures pressure relative to vacuum -Widely available -Relatively cheap -Requires additional sensors to measure local conditions -Slightly more -Measures difference expensive than gauge between two locations and absolute 83 Pressure Sensor Options Pressure Sensors Volume Cost Weight Height Length Width Temp Range Power Accuracy *** Time PX138 * $85 --- 26.2mm 28.1mm 27.9mm 0 to 50 °C 8VDC 0.1% 0.5% 1 week shipping PX139 * $85 --- 26.2mm 28.1mm 27.9mm 0 to 50 °C 5VDC @2 mA 0.1% 0.5% 1 week shipping PX140 * $120 --- 26.2mm 28.1mm 27.9mm -18 to 63 °C 8VDC 0.75 % 0.15% 1 week shipping Diameter Length 12mm 57.9mm -54 to 121 °C 24VDC @ 15 mA 0.25% 0.25% 1 week shipping Model PX209 ** $195 --- 84