Subpart OOO Requirements - Florida Department of Environmental

advertisement

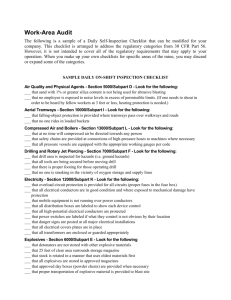

Workshop for Nonmetallic Mineral Processing Plants (NMMP) and Affected Asphalt Plants Air Resource Management Southwest District Office Mara Nasca Air Program Administrator Cindy Zhang-Torres Air Permitting Supervisor Danielle D. Henry Air Compliance Supervisor Cindy Falandysz Air Enforcement Supervisor Susan Pelz Solid Waste Supervisor Natrevia Gradney, Engineering Specialist Max Grondahl, Environmental Specialist Nancy Knight, Engineering Specialist 2 • Nonmetallic Mineral Processing (NMMP) Plant General Permit (GP) Requirements • New Requirements in 40 CFR 60, New Source Performance Standards (NSPS) Subpart OOO • Operating a RAP Crusher at Asphalt Plants • Waste Processing Facility Permit Requirements 3 4 General Conditions in Rule 62-210.310(3), F.A.C. ◦ http://www.dep.state.fl.us/air/rules/fac/62-210.pdf Specific Conditions ◦ ◦ ◦ ◦ ◦ Fuel consumption limits Controlling unconfined particulate matter Controlling yard dust General visible emission requirement Subpart OOO requirements Title 40, Code of Federal Regulations (CFR), Part 60, Subpart OOO; 60.670-676 ◦ Initial performance tests ◦ Annual performance tests ◦ Relocation requirements Conditions for collocation Non-routine use at non-Title V facilities 5 • Total fuel consumption shall not exceed: • 23,000 gallons per year of gasoline • 275,000 gallons per year of diesel • 1.3 million gallons per year of propane • 44 million standard cubic feet per year of natural gas • Equivalent amount if multiple fuels used. 6 Unconfined emissions from all relocatable nonmetallic mineral processing plants, except those located at mines or quarries and processing only material from onsite natural deposits, and all stationary nonmetallic mineral processing plants that process dry material shall be controlled by using a water suppression system with spray bars located wherever unconfined emissions occur at the feeders, the entrance and exit of the crushers, the classifier screens, and the conveyor drop points. 7 8 Unconfined emissions generated by vehicular traffic or wind shall be controlled by applying water (by water trucks equipped with spray bars) or effective dust suppressants on a regular basis to all stockpiles, roadways and work yards where the nonmetallic mineral processing plant is located. 9 Visible emissions from any emission point not subject to Subpart OOO shall be less than 20% opacity. 10 Types of subject units Types of excluded units Particulate matter standards Test methods and procedures Reporting and recordkeeping 11 • The following are types of subject units (affected facilities*) • • • • • Crushers Grinding mills Screening operations Bucket elevators Belt conveyors • Bagging operations • Storage bins • Enclosed truck or railcar loading stations *In the context of Subpart OOO, “affected facilities” refers to facility components. 12 Types of subject units ◦ Crushing of concrete and asphalt pavement is subject to Subpart OOO, because both types of materials are generally composed of nonmetallic minerals listed in 40 CFR 60.671(a) to (r). (EPA Applicability Determination Index, Control Number: NR42) Types of excluded units ◦ Underground mining operations. ◦ Some equipment associated with hot mix asphalt plants and portland cement plants are excluded. 13 • Types of excluded units – Fixed sand and gravel plants and crushed stone plants with capacities of 25 tons per hour or less. – Capacity means the cumulative rated capacity of all initial crushers that are part of the plant. – Portable sand and gravel plants and crushed stone plants* (e.g. limestone, granite, shell, quartz) with capacities of 150 tons per hour or less. – Common clay plants and pumice plants with capacities of 10 tons per hour or less. *RAP crushers fit into this category. 14 EPA Applicability Determination Index further defines “capacity” as based on manufacturer’s rating. (Control Number: NR122) o Example: “The Barmac crusher and associated conveyors are subject to Subpart 000 because the Barmac crusher has a rated capacity greater than 150 tons per hour. Although Central Rock claims that, because of the size of the feed material and product, the Barmac crusher can not process more than 150 tons per hour, Subpart 000 is based on the actual rated capacity of the affected facility which is 260 tons per hour for this Barmac crusher according to the manufacturer.” 15 Types of excluded units ◦ Plants built before, and not modified or reconstructed after, August 31, 1983. ◦ Modification – any physical change in, or change in the method of operating of, an existing facility which increases the amount of any air pollutant or causes any new air pollutant to be emitted. (40 CFR 60.2) ◦ Reconstruction—40 CFR 60.15(b) “Reconstruction” means the replacement of components of an existing facility to such an extent that: (1) The fixed capital cost of the new components exceeds 50 percent of the fixed capital cost that would be required to construct a comparable entirely new facility, and (2) It is technologically and economically feasible to meet the applicable standards set forth in this part. 16 • Standards for particulate matter – On and after the 60th day after achieving the maximum production rate at which the affected facility will be operated, but not later than 180 days after initial startup, no owner or operator subject to the provisions of this subpart shall cause to be discharged into the atmosphere from any transfer point on belt conveyors or from any other affected facility any fugitive emissions which exhibit greater than 10 percent opacity except as provided below. 17 Definitions ◦ “Transfer Point” A point in a conveying operation where the nonmetallic mineral is transferred to or from a belt conveyor except where the nonmetallic mineral is being transferred to stockpile. (40 CFR 60.671—Definitions) ◦ “Affected facility” Crusher, grinding mill, screening operation, bucket elevator, belt conveyor, bagging operations, storage bin, enclosed truck/rail loading station, RAP crusher at asphalt plants. 18 19 Standards for particulate matter ◦ Exceptions to 10% opacity limit requirement The opacity limit for fugitive emissions from any crusher in which a capture system is not used is 15%. Truck dumping (also includes using a front end loader, track hoe, etc.) of minerals into any screening operation, feed hopper, or crusher is exempt from Subpart OOO requirements. 20 Truck dumping: <20% standard, no testing Conveyor transfer Point (underbelt to stacker): 10% Conveyor to stock pile: <20% standard, no testing Crusher (in & out), 15% standard 21 *Note: When submitting a General Permit registration or renewal application for a crusher subject to Subpart OOO, it may be beneficial to include a flow chart describing plant components and operation. 22 Standards for particulate matter Wet screening operations: a screening operation at a nonmetallic mineral processing plant which removes unwanted material or which separates marketable fines from the product by a washing process which is designed and operated at all times such that the product is saturated with water. Wet mining operations: a mining or dredging operation designed and operated to extract any nonmetallic mineral regulated under this subpart from deposits existing at or below the water table, where the nonmetallic mineral is saturated with water. 23 Test methods and procedures The test methods and procedures in Subpart OOO are being revised, and the new requirements will be discussed later in the presentation. 24 Reporting and recordkeeping ◦ The owner or operator shall submit written reports of the results of all performance tests conducted to demonstrate compliance with standards. ◦ The owner or operator of any screening operation, bucket elevator, or belt conveyor that processes saturated material and is subject to the wet material processing standards and subsequently processes unsaturated materials shall submit a report of this change within 30 days following such change. Likewise if a process is changed from dry material to wet material, a report must be submitted within 30 days. 25 Reporting and recordkeeping – Notification of the actual date of initial startup of each affected facility shall be submitted. • The notification may be submitted for a combination of affected facilities in a production line that share the same initial startup date. The notification shall be postmarked within 15 days after such date and shall include a description of each affected facility, equipment manufacturer, and serial number of the equipment, if available*. • For portable plants, the startup notification shall include both the home office and the current location of the portable plant. *If the equipment manufacturer or serial number are unavailable, this should be specified in the initial startup notification. 26 For facilities subject to Subpart OOO, initial performance tests for visible emissions shall be conducted in accordance with the requirements of Subpart OOO and Subpart A. Within 60 days after achieving the maximum production rate at which the affected facility will be operated, but not later than 180 days after initial startup of such facility, the owner or operator shall conduct performance test(s) and furnish the Administrator a written report of the results of such performance test(s). 27 For facilities subject to Subpart OOO, annual compliance tests must be performed pursuant to Rule 62-297.310, F.A.C. and in accordance with the test methods and procedures set forth at Subpart OOO. Test results shall be reported in accordance with the provisions of Rule 62-297.310, F.A.C. 28 Rule 62-297.310, F.A.C. ◦ ◦ ◦ ◦ Operating rate during testing Observation period Reporting Test frequency Subpart OOO (previously discussed) 29 • Rule 62-297.310 F.A.C. – Operating rate during testing • Testing of emissions shall be conducted with the emissions unit operating at permitted capacity. If it is impracticable to test at permitted capacity, an emissions unit may be tested at less than the maximum permitted capacity; in this case, subsequent emissions unit operation is limited to 110 percent of the test rate until a new test is conducted. Once the unit is so limited, operation at higher capacities is allowed for no more than 15 consecutive days for the purpose of additional compliance testing to regain the authority to operate at the permitted capacity. 30 • Rule 62-297.310, F.A.C. – Observation period • The required minimum period of observation for a compliance test shall be sixty (60) minutes for emissions units which emit or have the potential to emit 100 tons per year or more of particulate matter, and thirty (30) minutes for emissions units which have potential emissions less than 100 tons per year of particulate matter and are not subject to a multiple-valued opacity standard. The opacity test observation period shall include the period during which the highest opacity emissions can reasonably be expected to occur. −Reporting Test reports are required to be submitted to the Department within 45 days of the test date. 31 Rule 62-297.310, F.A.C. – Test Frequency ◦ Performance tests for visible emissions must be conducted annually. (The rule revision effective January 10, 2007 requires annual testing.) o Annually is considered once each calendar year (January 1December 31). ‣ DEP guidance memo DARM-OGG-18: http://www.dep.state.fl.us/air/rules/guidance/ogg18.pdf 32 Relocation requires notification to the Department by telephone, e-mail, fax, or written communication at least one business day prior to moving and transmit by e-mail, fax, post or courier, a Facility Relocation Notification Form no later than five business days following relocation. Relocation Notification Form located online at: http://www.dep.state.fl.us/air/rules/forms/relocation.htm 33 A crusher using a general permit may be located with other facilities that separately registered for, and are also using, the NMMP plant air general permit, and with facilities using the concrete batch plant air general permit, even if under the control of different persons as long as the following conditions are met. The following types of units and activities may collocate ◦ ◦ ◦ ◦ Concrete batching plants using air general permits NMMP plants using air general permits NMMP plants exempt from permitting Other emission units and pollutant-emitting activities exempt from permitting 34 Site-wide fuel usage limitations apply to the collocation site. ◦ Total fuel consumption limits applied to the collocation site*: 23,000 gallons per year of gasoline 275,000 gallons per year of diesel 1.3 million gallons per year of propane 44 million standard cubic feet per year of natural gas An equivalent prorated amount if multiple fuels are used *Site: One or more contiguous or adjacent properties under control of the same person (or persons under common control). (Rule 62210.310(5)(e)1., F.A.C.) 35 Recordkeeping requirements ◦ The owners or operators of all collocated concrete batching plants and NMMP plants shall maintain records to account for site-wide fuel consumption for each calendar month and each consecutive twelve months. The owners or operators shall retain these records, available for Department inspection, for at least five years. 36 Non-routine use at facilities with air construction or air operation permits is allowed as long as the following conditions are met: ◦ The NMMP plant must not be located at a single site for more than six months in any consecutive 12 months ◦ Records must be kept that indicate how long the NMMP plant has been at the permitted facility ◦ No NMMP plant using an air general permit shall perform a routine task at a permitted facility unless the NMMP plant operation is authorized by the permitted facility’s AC or AO permit. RAP crushing at an asphalt plant is considered a routine task. 37 38 Proposed Effective Date in State Rules is October 16, 2009 •NMMP NSPS applies to affected facilities for which construction, modification, or reconstruction commenced on or after August 31, 1983. •These final amendments include revisions for affected facilities for which construction, modification, or reconstruction commenced on or after April 22, 2008. 39 Monitoring Requirement Initial Testing Requirements for Fugitive Emissions Fugitive Emission Limits Initial Testing Notification Requirements Recordkeeping and Report Requirements 40 NAICS Code Industry 2123 Nonmetallic Mineral Mining and Quarrying 2211 Electric Power Generation, Transmission and Distribution 3241 Petroleum and Coal Products Manufacturing 3271 Clay Product and Refractory Manufacturing 3273 Cement and Concrete Product Manufacturing 3274 Lime and Gypsum (natural and synthetic) Product Manufacturing 3279 Other Nonmetallic Mineral Product Manufacturing (Ground or Treated Mineral and Earth Manufacturing) 41 § 60.674 Monitoring of operations. (b) If a wet suppression system is used to control emissions, facility must perform monthly periodic inspections to check that water is flowing to discharge spray nozzles in the wet suppression system. *Note: Only facilities constructed, modified, or reconstructed on or after April 22, 2008. 42 § 60.675 Test methods and procedures. From To (c)(3) When determining compliance with the fugitive emissions standard, the duration of the Method 9 observations may be reduced from 3 hours (thirty 6minute averages) to 1 hour (ten 6-minute averages) if no individual readings are > 10 percent and there are no more than three readings of 10 percent for the 1hour period. (c)(4) Deleted (crushers w/o capture systems) (c)(3) When determining compliance with the fugitive emissions standard, the duration of the Method 9 (40 CFR part 60, Appendix A–4) observations must be 30 minutes (five 6-minute averages). *Note: For all facilities subject to Subpart OOO. 43 § 60.675 Test methods and procedures. (e)(2) A single visible emission observer may conduct visible emission observations for up to three fugitive, stack, or vent emission points within a 15-second interval if the following conditions are met: (i) No more than three emission points read concurrently (ii) All three emission points must be w/i a 70 degree viewing angle in front of the observer such that the proper sun position can be maintained for all three points. (iii) If opacity reading for any one of the three points is the applicable standard, then the observer must stop taking readings from the other two points and continue reading just the single point. *Note: For all facilities subject to Subpart OOO. 44 TABLE 3 TO SUBPART OOO—FUGITIVE EMISSION LIMITS For * * * The owner or operator must meet the following fugitive emissions limit for grinding mills, screening operations, bucket elevators, transfer points on belt conveyors, bagging operations, storage bins, enclosed truck or railcar loading stations or from any other affected facility (as defined in §§ 60.670 and 60.671) * * The owner or operator must meet the following fugitive emissions limit for crushers at which a capture system is not used * * * The owner or operator must demonstrate compliance with these limits by conducting * * * Affected facilities (as defined in §§ 60.670 and 60.671) that commenced construction, modification, or reconstruction after August 31, 1983 but before April 22, 2008. 10 percent opacity 15 percent opacity An initial performance test according to § 60.11 of this part and 60.675 of this subpart. Affected facilities (as defined in §§ 60.670 and 60.671) that commence construction, modification, or reconstruction on or after April 22, 2008. 7 percent opacity 12 percent opacity An initial performance test according to § 60.11 of this part and §60.675 of this subpart; and Periodic inspections of water sprays according to § 60.674(b) and § 60.676(b); and A repeat performance test according to § 60.11 of this part and § 60.675 of this subpart within 5 years from the previous performance test for fugitive emissions from affected facilities without water sprays. Affected 45 facilities controlled by water § 60.675 Test methods and procedures. From To (g) If after 30 days notice for an initial scheduled performance test, there is a delay in conducting any rescheduled performance test required in this section, the owner or operator of an affected facility shall submit a notice to the Administrator at least 7 days prior to any rescheduled test. (g) For performance tests involving only Method 9 (40 CFR part 60 Appendix A–4) testing, the owner or operator may reduce the 30-day advance notification of performance test in §60.7(a)(6) and 60.8(d) to a 7-day advance notification. *Note: State Rule 62-297.310(7)(a)9,F.A.C.,requires a 15-day advance notification. 46 § 60.675 Test methods and procedures. (i) If the initial performance test date for an affected facility falls during a seasonal shut down* of the affected facility, then with approval from the permitting authority, the owner or operator may postpone the initial performance test until no later than 60 calendar days after resuming operation of the affected facility. * Seasonal shut down means shut down of an affected facility for a period of at least 45 consecutive days due to weather or seasonal market conditions. 47 § 60.676 Reporting and recordkeeping. (b)(1) Record each monthly periodic inspection required under §60.674(b) or (c), including dates and any corrective actions taken, in a logbook (in written or electronic format). The owner or operator must keep the logbook onsite and make hard or electronic copies (whichever is requested) of the logbook available to the Administrator upon request. *Note: Only facilities constructed, modified, or reconstructed on or after April 22, 2008. 48 § 60.676 Reporting and recordkeeping. From To (h) The subpart A requirement under § 60.7 (a)(2) for notification of the anticipated date of initial startup of an affected facility shall be waived for owners or operators of affected facilities regulated under this subpart. (h) The subpart A requirement under § 60.7 (a)(1) for notification of the date construction or reconstruction commenced is waived for affected facilities under this subpart. 49 § 60.676 Reporting and recordkeeping. (k) Notifications and reports required under this subpart and under subpart A of this part to demonstrate compliance with this subpart need only to be sent to the EPA Region or the State which has been delegated authority according to § 60.4(b). 50 New Format for Asphalt Plant Permits •RAP Crushing System Specific Conditions 51 52 Rule 62-701.200, F.A.C. – Definitions Rule 62-701.300, F.A.C. - Prohibitions Rule 62-701.220(2)(d), F.A.C. Industrial by-products – solid waste permit not required Majority must be sold, used or reused within 1 year Cannot be hazardous wastes Must be managed in such a way that Department air or water quality standards or criteria are NOT violated Rule 62-701.710, F.A.C. Waste processing facilities – solid waste permit required Engineering drawings, site plans, operation plan, calculations, etc. 53 Asphalt road base & concrete crushing operations 54 Asphalt road base & concrete crushing operations 55 Asphalt road base & concrete crushing operations Generally meet definition of industrial by-products if BMPs are followed no solid waste permit required BMPs need to include: Only clean concrete and asphalt road base material is received Residues from processing (incidental plastic, wood, metal) must be containerized and removed at least weekly for offsite disposal 56 Waste processing facility Solid waste permit required 57 Waste processing facility Solid waste permit required 58 Waste processing facility Solid waste permit required 59 60