Some Ingredient for Hair Care Product

advertisement

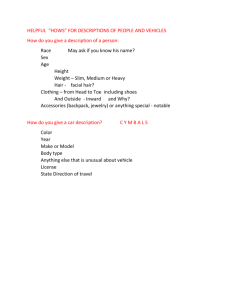

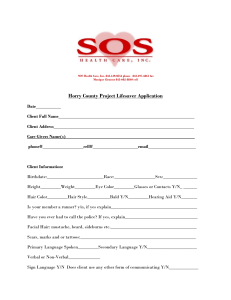

Hair Care Products Assoc. Prof. Dr.Pleumchitt Rojanapanthu Pharmacy Department, Faculty of Pharmacy Mahidol University, Bangkok, Thailand 1 Hair Care Products : Shampoos Hair sprays Conditioners Hair gels “2 in 1” shampoos Perming solutions Hair dyes., etc. 2 Shampoos Purpose of shampoo is to clean hair Customer also expect a dense and luxurious lather Basic or primary surfactants are backbone of the cleansing products are necessary 3 Shampoos Shampoos can be made in various physical form: Liquids, creams, paste, aerosol and dry majority are liquids, either clear or pearlised The principle constituents of most liquid shampoos can be classified as : Primary detergents Secondary detergents Thickeners 4 Shampoos (con.) • Foamers • foam stabilizers and booster • Perfumes • Preservatives • Diluents (usually water) • conditioning agents 5 Shampoos (con.) • Other additives (functional or otherwise) • pearlisers / opacifiers • colours Remark : many ingredients are multifunctional and therefore do not clearly fall into any one category 6 Shampoos (con.) The surfactants used in a shampoo need to be selected on the basis of a whole range of properties including: • • • • costs foam height foam texture detergency 7 Shampoos (con.) • • • • • • • irritancy ease of handling and mixing compatibility with other ingredients color odor purity biodegradability 8 Surfactants Basic anionic surfactants (Primary, anionic surfactants) Mild anionic surfactants (Secondary, anionic surfactants) Amphoteric surfactants Nonionic surfactants Cationic surfactants 9 Basic surfactants 1. Alky ether sulfates (R- (OCHCH2)xSO4M) are most widely used surfactants Exhibit well balanced properties Excellent foamer, through the foam structure is relatively coarse Low CMC (critical micelle concentration) ideal for cleansing preparation 10 Basic surfactants (con.) Ideal behavior regarding foam and detergency Be easily thickened with salt Show good water solubility Skin and eye compatibility is acceptable Lauryl ether sulfate / sod. Laureth sulfate 11 2. Alkyl sulfates (R-SO4m) The first synthetic surfactant Still most popular Excellent foamer Producing rich and creamy foam 12 3. a- Olefin sulfonates A mixture alkene of sulfonates and hydroxy alkane sulfonates Milder than alkyl sulfonate Similar irritation to the alkyl ether sulfate Stable both in acidic and alkali pH values 13 Mild Anionic Surfactants (Secondary surfactants) The purpose is to improve skin and eye compatibility of the formulation Mild surfactant usually show reduction of foaming and cleansing compared with basic surfactant 14 Sulfosuccinate Derivative of sulfosuccinic acid both mono and diesters Most popular derivative used in Europe is disodium laureth sufosuccinate Good foamer and relatively cheap Instability in both low and high pH value Stable at pH 6-6.5 15 Cocoyl isethionate (RCOOH-CH2-CH2-SO3Na) Mainly used as a surfactant in syndet bars Improve skin compatibility Excellent skin compatibility and emolliency properties Using in baby products and in facical wash formulations Maximum stability at pH 5-7 16 Alkyl ether carboxylates (R-(OCH2-CH2)x-OCH2-COOM) Mild surfactant, reduce foaming and cleansing Skin compatibility is similar to that of alky; ether sulfate Stable at low pH value 17 Magnesium surfactant Have significantly better skin compatibility > Sod., amm. and amine neutralized Show high foaming and excellent cleansing properties Their applicational properties are practically unchanged compared with the sodium foam Magnesium ion increase the resistant of microbe 18 Alkyl phosphate Mono alkyl phosphate is good surfactant Show high foam with mildness to skin Suitable for mild shampoo and show both Di- and tri- are known as emulsifier 19 Amphoteric surfactants The charge changes as a function of pH value of the formulation Build complex with anionic surfactant Exhibit milder properties than individual 20 Alkyl betaines Can be cationic or anionic depend on pH At pH 5-7 as in shampoo, they form ionic complex with anionic surfactant Improve the skin compatibility of an anionic formulation The size of micelle viscosity Can improve foaming of a formulation (often use for thickening the formulation) Improve structure of the foam finer and creamy 21 Alkylamido betaines Amino betaines are milder than alkyl betaines Lower price Much more often use in cosmetics 22 Acylamphoglycinates and acylamphopropionates Most important products are coco derivative Good skin compatibility Show some conditioning properties in shampoos Excellent foamer but is not stable in hard water 23 Amino oxides Amino oxides are never anionic Show cationic, non-ionic depend on pH in combination with anionics can act as a foam booster and improve the foam structure Good thickener for ionic surfactant Are good conditioning agents in hair rinsing 24 Non-ionic surfactant Ethoxylated products Poor foaming used in shampoo Often adds as solubilizers for perfume Extraordinary mildness, used as the main surfactant in ‘non-sting’ baby-shampoo 25 Alkyl polyglycoside (APG) Not as good as anionic surfactant Shows good foaming properties Excellent skin compatibility Normally use for secondary surfactant 26 Shampoos (con.) “frequent use” shampoos contain higher levels of milder secondary surfactants many secondary surfactants exhibit lower irritation to skin and eyes small addition of secondary surfactant can lead to a significant decrease irritation 27 Evaluation of Detergents as Shampoo Bases Ease of spreading Lathering power Efficient soil removal Ease of rinsing 28 Evaluation of Bases Ease of combing wet hair Lustre of the hair Speed of drying Ease of combing and setting the dry hair Safety of shampoo 29 Detergency Detergency : the removal of dirt, involving the following processes : ability to wet both the dirt and substrate reducing the interfacial tension dispersing the dirt particles 30 Shampoos Additives Thickeners High viscosity is very important both for Product stability Handling The product should have viscosity between 400 and 4000 m Pas 31 Thickeners (con.) Pearlescent products should have minimum viscosity of 2,000 m pas it avoid precipitation Ether sulfate + electrolytes (Cl-) viscosity by the size of the micelle Alkanolamide formulation the cloud point of the 32 Thickeners (con.) Using the special high molecular weight thickener ; PEG 6,000, PEG 120 It is either product, remain stable against hydrolysis at higher temperature or extreme pH values Polymer thickener Natural gum Cellulose derivative 33 Foam stabilizer In the present of oil, such as sebum, Monoethanolamines are the most effective 34 Pearlescent agents Ethylene glycol mono and ditearate (EGMS,EGDS) are most often used in surfactant formulations. They have to be incorporate at high temperature (70 -75) Ready – made liquid pearlescent bases are now popular 35 Conditioning agents Shampoo with anionic surfactants leave hair difficult to comb while wet flyaway when comb after drying Addition of conditioning agents wet – combability static charge 36 Conditioning agents (con.) Cationic surfactants show good properties but incompatable with anionic surfactants Using quaternized polymer : quaternize hydroxyethyl cellulose (Poly quaternize 10) compatible with most anionic surfactant Show excellent conditioning properties 37 Conditioning agents (con.) Impart manage-ability and body to hair very low concentrations are sufficient Due to its very high substantively to hair, very low concentrations (0.5%) are sufficient High concentration may lead to overconditioning and build up on the hair 38 Conditioning agents (con.) Small amount of fatty component : fatty alcohol, monoglyceride can support condition effect of shampoo Silicone can be very effective conditioners, but are very difficult to incorporate and may act as antifoaming agents 39 Thickeners and foam stabilizers Alkalonamides or their alternatives Polymeric materials Electrolytes Many of these ingredients are multifunctional, and most product use more than one. 40 Thickeners (con.) Some surfactants systems are difficult to thicken not responding well to electrolyte additions most surfactants systems are nonNewtonian, exhibit shear – thinning shear – thickening time – dependence time – independence yield point etc. 41 Thickeners (con.) Ultimate test viscosity should be carefully considered Various raw materials manufactures have developed PEG derivatives Polymeric material : natural gums Gum-thickened product have a different Rheology to otherwise similar electrolyte-thickened product 42 Thickeners (con.) Temperature effect is less for gum systems than for an electrolyte-thickened system This can be useful when formulating for climates where the product might be subjected to large temperature variations in storage, distribution and use 43 Thickeners (con.) Gum will often stabilize foam by strengthening the film at the air/liquid interfaces in the matrix of bubbles Making foam feel denser (creamy) in use It is sometimes apparent as soon as the shampoo is poured into the hand 44 Some disadvantages high cost lengthened processing time (with higher energy consumption if hot process is used) difficulty of making viscosity adjustment This problem can often overcome by using a small amount of electrolyte for final viscosity adjustments. 45 Effect of electrolyte on viscosity of surfactant systems ionic density of the solution consequent effect on micelle size and shape Adding an electrolyte with the same cation as that of primary anionic surfactant in the system e.g: amm.chloride amm.lauryl sulfate sod. chloride sod.lauryl ether sulfate 46 Effect of electrolyte (con.) Addition of electrolyte beyond a certain point will cause thinning, quite rapid and The maximum in viscosity depends on: Concentration presence of alkalotamides level of free fatty alcohol effect of the perfumes 47 Effect of electrolyte (con.) Maximum viscosity occurs at low concentration of electrolyte when free fatty ether and alkalonamides are present Due to formation of mixed micelles Should have experimental for the relationship of viscosity and electrolyte concentration 48 Preservatives Ensure that the products contain no pathogenic … Variety of preservatives are available: parabens Imidazolidinyl ureas 2-Bromo-2-nitropropane-,1,3-diol 5-Bromo-5-noitro-1,3-dioxane Dimethyl dimethylol (DMDM) hydantoin 49 Preservatives (con.) Methyl chloroisothiazodlione and methylisothiazodlione Pohenoxethanol Drazolidinyl urea Methy dibromoglutatonitrile Questernium – 15 Sodium iodate Glutaraldehyde 50 Preservatives (con.) Many surfactants used for shampoo manufacture are already preserved Addition of preservatives must be taken into account Challenge test of the finished product must be performed 51 Opacifier and pearliser Opacification of shampoos usually for aesthetic reason An occasionally a useful technique to use when the product can’t be made completely clear 52 Opacifier (con.) Opacification may be achieved simply by Adding a small of fine, intensely white polymer dispersion For ease of dispersion and subsequent product stability dilution of the opacifer to a 10% solution with water before addition to the main mix 53 Three common used ways achieving Pearlescence using stearate Buying a ready made pearlised base (need dilution before adding) Adding the chosen pearlising agents to the hot mix (most commonly ethylene glycol mono-desperate) Buying a highly concentrated pearlising agent in a liquid or semi-liquid form that may be added as a cold mix 54 Factors affecting the appearance of the ‘pearl’ 1. Composition of stearate ester 2. Presence of alkanolamides and other materials 3. Rate of cooling 4. Shear rate of stirring 5. Composition of the base 55 Conditioning agents The majority of active conditioning agents are cationic surfactants, incompatible with anionic surfactants which are the basis of nearly all shampoos The properties of both cationic and anionic can be modified 56 Variety other materials have been used as conditioning agents in shampoo Various vegetable oil Vitamin Lanolin and its derivative Herbal extracts Some specialty silicone 57 Color Using color which meet both EC and US specifications whenever possible Higher purity colors are more expensive than technical grades Color stability should be considered Color fading can be minimize by adding a suitable UV absorber 58 Water soluble absorbers usually work best in shampoos Bensophenone-4 and 2 (0.05-0.1%) Color should be added in solution, not as solid material Aqueous solution color required preservative 59 Sequestrants Such as EDTA (ethylene diamine tetraacetic acid) salts added in low level To aid rinsing in hard water To boost the efficiency of preservative 60 Anti-build-up shampoos Are formulate to help remove excess build-up of conditioning agents and styling aids 61 Hair conditioners Conditioning Means many things to many people : Reduction of fly-away Gloss Sheen Manageability Ease of handling Simply general overall appearance 62 Conditioner should impart the condition of the hair as follow : Improved wet and dry combing Reduced fly-away (antistatic) Increase gloss and volume Improve curled retention Repair the damage of hair shaft Increase moisturing 63 Basic ingredients in the formulation Primary surfactants (nearly always cationic) Polymers Bodying agents Auxiliary emulsifiers Oily components Other ‘active’ ingredients 64 Conditioners (con.) Thickeners Perfumes Preservative Diluents (usually water) Colors Other non-functional ingredient 65 Cationic surfactants The most common active ingredients: quaternary ammonium compound (quats) properties related to charge density Highly charged cationic will be more strongly attracted to the negatively charged hair surface 66 Cationic surfactants (con.) On the hair surface, the number, shape and size of the fatty chain in mol. are determinants Two fatty acid chains > lubricity than one chain Long chain > effective lubricant than short chain 67 Bodying agents Conditioners are perceived to be more effective when thick and creamy Using high level of fatty alcohol along with other waxy esters 68 Auxiliary emulsifiers Some quats are good emulsifiers, some are not Incompatibility with anionic surfactants Surfactants emulsion stability can’t be obtained with cationic alone Non-ionic surfactants are in used Choosing 2 surfactants : should consider HLB (Hydrophilic Lipophilic Balance) 69 Oil components Should be considered the effect of oil on : Ease of manufactures Product stability Using at typically low level, less affecting stability Small quantities of exotic oil with attractive names may be included 70 Thickeners Salt solution are in used Add only very small amount at a time (viscosity will peak at low concentration than in shampoo) Add salt solution when emulsion is cold (maximum 30 oC) Use dilute salt solution (10% max) add very slow with continue stirring Small amount of salt solution with high-shear mixing Try a small batch and scale up carefully 71 Manufacturing Using two phases method Heating oil and water phases Combining together Cooling process According to high water phase /oil ratio Only part of water is heated is formed a concentrate emulsion Adding the rest of water at cold stage 72 Clear Conditioners Using aqueous solution of quarts, polymers, or both Conditioning other active ingredients such as : Parthenol, water-soluble silicone derivative Thickening by electrolyte as shampoo Developing quite strong lather 73 “2-in-1” shampoos - contain both cleansing and high levels of conditioning agents - over 20% shampoos are sold of this type - silicone is the basic substance derive from natural substances 74 How 2-in-1 formulations work: (1) surfactant molecules (blue)and conditioner particles (pink) surround the hair; each conditioner particle is trapped inside a crystal 'cage' 75 (2) The surfactant molecules are attracted to the dirt on the hair surface and lift it away, leaving the hair clean 76 (3) When the hair is rinsed, the conditioner particles are released from their 'cages'; they are not washed away but, because of their electrical charge (+), they are drawn towards the (-) charges of the hair 77 4) They cling to the hair, smoothing out any roughness on the surface and protecting the cuticle 78 Hair thickener Hair can be made thicken by Causing it to swell Coating it to increase its diameter Hair will be swollen in water / more under alkali conditions Powerful humectants may be used to increase moisture content of hair Application of panthenol solution cause the swelling of hair 79 Styling aids Hair Sprays, Hair gels Various description terms : Light hold, medium hold, strong hold, ultra hold, mega hold The main ingredients in hair sprays are : Polymer Plastizer Perfume Solvent Neutralizer Other addition 80 Polymers Ideal hair spray polymer should be soluble in ethanol Hydrophilic enough is be easily removed from hair by shampooing Hydrophilic enough to compatible hydrocation propellants 81 Polymers (con.) Should give powerful hold without brittleness Easily remove by combing or brushing Must be good adhesion and not sticky For example : Vinyl pyrrolidone derivative Vinyl acetate etc. 82 Solvent Non-aerosol product Ethanol alone or slightly dilute with water Excellent solvent for most resins The addition of water to solvent system may be necessary: To improve water solubility of ingredients To retard evaporation salt To reduce cause To prevent perception from on acid-resin based system 83 Plasticizers Using to modify the properties of polymer flim Making it more flexible Only small quantities are normally required (0.5% of dry weight polymer) For examples: Ester Various silicone Protein Polyol Lanolin derivatives 84 Neutralizer Calculated from the acid value of the resin Can be obtained from polymer 85 Hair Gels Majority of gels on the market are aqueous/ aqueous alcoholic Carboxyvinyl polymer are the most important/ carbomer 940 • • • • Create the clear gel foam Have some fixative power Contribute to overall hold of the formulation As a primative film former 86 Hair gels (con.) Carbomer 940 gives the clearest gel • Degrades by UV light: loss of viscosity and clarity • Overcome by adding UV absorber • Sensitive with metal ion => catalyst gel to be degrade • Addition of EDTA is an effective way 87 Permanent Waving Mode of action is as follows: Reduction of –S-S- bonds between cystine amino acid groping on an adjacent polypeptides chains Reassignments of hair into its new position Reforming of the –S-S- bonds by oxidation the various –SH residues will be linked into new partners on the adjacent chains 88 Factor affecting the efficacy of the product Processing time Processing temperature Concentration of reducing agent Ratio of lotion to hair quantities Penetration of the lotion pH The nature and the condition of untreated hair 89 Permanent waving Waving lotion are available in various physical foams Clear, cloudy liquid, cream or lotion, gel or thickened liquid Using low conductivity, demineralised water Using equipment made of 316 grade stainless steel or prolypropylene for all contact parts Avoiding heavy metal contamination which may be decompose the products and produce discoloration 90 Permantent waving (con.) The addtion of sequestrans is needed Emulsion type or gel-type product: • Required hot processing • Thioglycollate should be added last after cooling the mix 91 Permantent waving (con.) The products can be extreme: • The products is at high pH and strong reducing • The sulfphide odour emitted during processing of the hair are very hard to mask 92 Neutralisation The reforming of the –S-S- bonds by oxidation Oxidation is commonly carried out by hydrogen peroxide (easier using than the other oxidizing agent) With a surfactant added to enhance penetration The solution may be clouded or produced in form of a pourable emulsion 93 Neutralisation (con.) Bromated, the second most popular type of neutralizer Since both waving lotion and neutralizers Usually have guite extreme pHs and exhibit considerable redox potential They are not particularly susceptible microbiological contamination 94 Effect of Air and Sunlight 95 Hair dyes Temporary, semi-permanent, permanent dyes Temporary dyes Any soluble colors can be used The color does not penetrate to the hair shaft Complete removable by a single shampoo 96 Hair dyes (con.) Another mean is by using color spray organic and inorganic pigments can be suspended in gum-thickened or emulsion base 97 Semi-permanent dyes Using dyestuffs whose cationic characteristic gives them a natural affinity of hair Metallised dyes are not very compatible with salt The blend of amphoteric, cationic, non-ionic surfactants with low salt levels is preferred Performance may be enhanced by the inclusion of solvents 98 Semi-permanent dyes (con.) Water causes considerable swelling of the hair shaft Aqueous solution with some solvents cause even more leading is greatly increasd dye uptake Hair has more pores near the end than the root Treated hair has more porous than untreated hair 99 Permanent hair dyes Permanent or oxidation dyes Consist of two parts - A dye intermediate solution and oxidizing agent - The latter always being hydrogenperoxide Dye intermediates are blended of primary intermediates and coupling agents or modifiers in a suitable base 100 Permanent hair dyes (con.) During the permanent dying of hair, the dye intermediate solution and oxidizing solution are mixed and applied to the hair The primary intermediate are gradually oxidized Then undergo coupling reaction with modifier 101 Permanent hair dyes (con.) The primary intermediate are all small molecules can penetrate the hair shaft, particularly the wet, alkali conditions during the hair application The oxidation and coupling reactions produce much larger molecules Many of which are then “trapped” in the hair shaft Thereby making the effect permanent 102 Some general remarks about product development: 1. Make sure that the discussion is clear, the brief should include, as minimum : • Require performance parameters in as much detail as possible 103 General remarks (con.) * * * * Benchmark product, unless the development is in a completely new area Guidelines on costs Purpose claims The required timing 104 General remarks (con.) 1. Do not produce a Rolls Royce when a mini would be sufficient 2. Do not use new raw materials if one from existing stocks will do 3. Specification often appear virtually identical alternative sources of supplier should be investigated 105 General remarks (con.) 4. Ensure reproducibility on scale up making use of suitable plant and equipment 5. Keep formulations as simple as possible 6. Try to develop products which can be made as cheap as possible: • with minimum energy requirement • minimum time for processing 106 107