6. Microbiological analysis of agricultural products

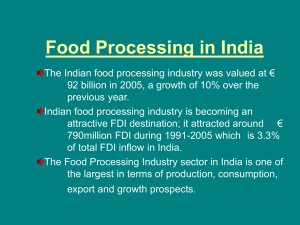

advertisement